2-Layer Soft Fluoropolymer Tubing TQ Series – Tubes SMC – Ống dây khí SMC

Product Description

2-Layer Soft Fluoropolymer Tubing TQ Series – Tubes SMC – Ống dây khí SMC

Tubing with a 2-layer structure.

[Features]

· Fluids such as solvents are transferred by flexible piping with superior abrasion resistance.

· Wearing of outer layer tube: Reduced to 1/30.

· Flexibility: Improved by up to 55% (*1). * 1: Compared with SMC Fluoropolymer Tubing / TL (ø6 [6‑mm diameter] × ø4 [4‑mm diameter]).

[Applications]

· Semiconductors, food, medical, machine tools.

Download

2-Layer Soft Fluoropolymer Tubing TQ Series – Tubes SMC – Ống dây khí SMC

Features Of 2-Layer Soft Fluoropolymer Tubing TQ Series

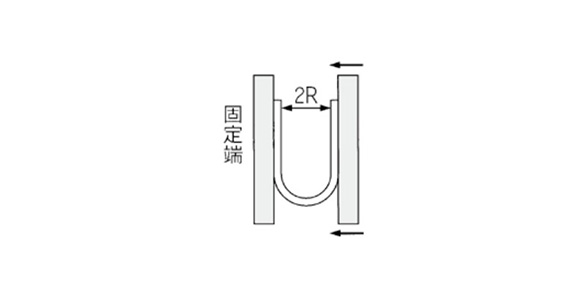

How to measure the minimum bending radius

Bend the tube into a U shape at a temperature of 20°C. Fix one end and bend the loop gradually at 100 mm/min. Measure 2R when the tube breaks or is crushed.

Applicable Fluid List

Fluids in the list below are chemically inert to tubing material. Possible physical effects may occur such as penetration and swelling due to temperature, pressure and chemical density. To use tubing in a solvent environment, tests should be performed under the same environment to ensure no problem occurs under the operating environment.

| Chemical | Inner layer | Outer layer |

|---|---|---|

| Special fluoropolymer | Special nylon resin | |

| Hydrochloric acid | ○ | △ |

| Sulfuric acid | ○ | △ |

| Nitric acid | ○ | × |

| Caustic soda | ○ | △ |

| Caustic potash | ○ | △ |

| Ammonia hydroxide | ○ | ○ |

| Hydrogen peroxide | ○ | △ |

| Water | ○ | ○ |

| Phenol | ○ | × |

| Benzene | ○ | △ |

| Toluene | ○ | △ |

| Xylene | ○ | △ |

| Carbon tetrachloride | ○ | × |

| Acetone | ○ | △ |

| Methyl ethyl ketone | ○ | △ |

| Chemical | Inner layer | Outer layer |

|---|---|---|

| Special fluoropolymer | Special nylon resin | |

| Citric acid | ○ | △ |

| Stearic acid | ○ | △ |

| Formic acid | ○ | △ |

| Ethyl acetate | ○ | ○ |

| Butyl acetate | ○ | △ |

| Methyl alcohol | ○ | ○ |

| Ethyl alcohol | ○ | ○ |

| Butyl alcohol | ○ | ○ |

| Isopropyl alcohol | ○ | ○ |

| Cellosolve | △ | △ |

| Hexane | ○ | △ |

| Cyclohexane | ○ | △ |

| Mineral oil ASTM No. 3 | ○ | ○ |

| Naphtha | ○ | ○ |

- 1. “Chemically inert” means to not cause any chemical reaction.

- 2. Criteria: ◯ Applicable, △ Not recommended, × Inapplicable

- 3. Applicable Fluid List shows the reference values based on test results performed under specific conditions. Application to products is not guaranteed.

- 4. Applicable Fluid List is for tube materials. For use in environments containing solvents, please contact SMC.

Series List And Specifications

| Nominal | TQ0425 | TQ0604 | TQ0806 | TQ1008 | TQ1209 | |

|---|---|---|---|---|---|---|

| Outer diameter (mm) | 4 | 6 | 8 | 10 | 12 | |

| Inner diameter (mm) | 2.5 | 4 | 6 | 8 | 9 | |

| Roll | 20 m | ● | ● | ● | ● | ● |

| 100 m | ● | ● | ● | ● | ● | |

| ColorNote 1) | Translucent (material color) | |||||

| FluidNote 2) | Air, water, inert gas, solvent | |||||

| Applicable fittingsNote 3) Note 7) | Insert fittings KF, KFG2, VCK Series Miniature fittings M, MS Series (Hose-nipple type) Fluoropolymer fittings LQ1, LQ3Note 6) |

|||||

| Maximum operating pressureNote 4) MPa | 20°C | 2.0 | 1.9 | 1.5 | 1.1 | 1.2 |

| Minimum bending radius (tube close bend radius)Note 5) mm | 4 | 9 | 26 | 42 | 37 | |

| Fluid temperature (fixed usage) | Air, inert gas: -20 to 100°C / Water, solvent: 0 to 70°C (No freezing) | |||||

| Material | Inner layer: special fluoropolymer, Outer layer: special nylon resin | |||||

- 1. There may be plasticizer (white powder) deposits on the external surface of the tube. Please exercise caution when using this item in a clean room. Otherwise, the clean level may decrease.

- 2. When solvent is used, make sure to test in the same environment as the actual operating environment, and confirm that no problem will occur under the operating conditions. The standard values of the Applicable Fluid List below are the reference values based on the results of tests performed under specific conditions. The product can be physically affected by temperature, pressure, chemical density, etc., causing permeation or swelling, and this may cause some problems.

- 3. Perform periodic maintenance inspections. If leakage continues to occur after tightening, replace the tube with a new one. If the tube will be used in a location where it moves, perform a test to make sure no problems occur under the actual operating conditions. When the product is used with motion for a long time, or at a high temperature, the tubes may leak due to deterioration of the materials.

- 4. Observe the lesser value of the maximum operating pressure between the tubing and fittings. The surge pressure must not exceed the maximum operating pressure. If the surge pressure exceeds the maximum operating pressure, it will result in damage to tubes and fittings. Furthermore, abnormal temperature rise caused by adiabatic compression may result in the tube bursting.

- 5. The minimum bend radius (tube close bend radius) is not guaranteed. The value of 2R is measured with a bent or flattened tube.

- 6. For the installation of fluoropolymer fitting LQ1 and LQ3, please contact SMC.

- 7. A fitting that seals the outer diameter of the tube such as a one-touch fitting is not applicable since it is in contact with the wetted part of the external layer nylon material.

TQ0425-20

TQ0425-100

TQ0604-20

TQ0604-100

TQ0806-20

TQ0806-100

TQ1008-20

TQ1008-100

TQ1209-20

TQ1209-100

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Là Đại lý uỷ quyền của Weller tại Việt Nam.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.

👉 Công ty Medin hỗ trợ:

![]() Tư vấn giải pháp tối ưu

Tư vấn giải pháp tối ưu

![]() Có sẵn sản phẩm dùng thử

Có sẵn sản phẩm dùng thử

![]() Hỗ trợ test tận nơi

Hỗ trợ test tận nơi

👉 Nếu bạn có bất kỳ yêu cầu nào, vui lòng liên hệ với chúng tôi.

☎️ Hotline: 0902782082

🌐 Website: https://www.medin.com.vn/

- VP Ho Chi Minh: 01 Đường 410C, Phước Long A, Tp. Thủ Đức

- Ha Noi Branch: 562 Nguyễn Văn Cừ, Long Biên, Hà Nội

- Da Nang Branch: 63 Phan Đăng Lưu, Hải Châu, Đà Nẵng