Electro-Pneumatic E-P HYREG VY1 Series – Bộ Chỉnh Áp Khí Nén SMC

Product Description

Electro-Pneumatic E-P HYREG VY1 Series – Bộ Chỉnh Áp Khí Nén SMC

The Electro-Pneumatic E-P HYREG VY1 Series is a hybrid regulator combining a regulator and a solenoid valve.

[Features]

· Stepless controls via electric signals.

· Simple circuit configuration.

· Easy to handle.

· Manifold capable.

[Applications]

· Cylinder thrust control.

· Drive and thrust control.

· Flow control of various fluids / Pressure control of tanks / Air flow control for nozzles.

Download

Electro-Pneumatic E-P HYREG VY1 Series Details – Bộ Chỉnh Áp Khí Nén SMC

Electro-Pneumatic E-P HYREG VY1 Series: product image (1)

Electro-Pneumatic E-P HYREG VY1 Series: product image (2)

Electro-Pneumatic E-P HYREG VY1 Series Specification

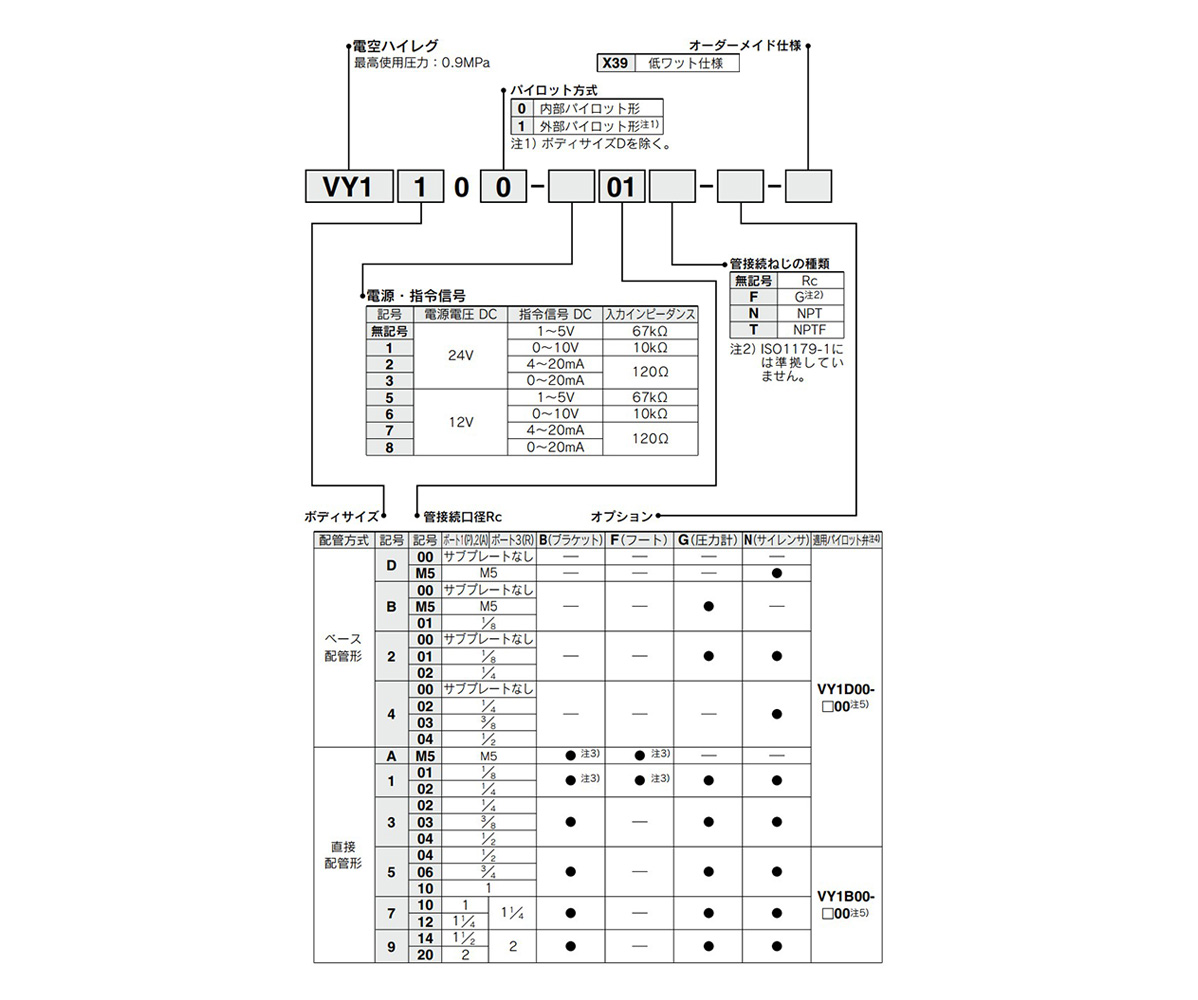

Model number notation (standard specifications)

Standard specification, Model number example

- *Note 3) Only the bracket or foot can be mounted. They cannot be mounted together.

- *Note 4) When the pilot valve is replaced, it may not satisfy characteristics such as accuracy. As such, be sure to check that the product works without problems under the operating conditions before using. If the manufacturer is asked to repair the product, the manufacturer will perform an inspection to confirm the characteristics.

- *Note 5) The □ in the applicable pilot valve part number designates the power source / command signal.

- *Note 6) Cut off the command signal when pressure control on the secondary (outlet) side is not required, such as when the line is temporarily halted, etc.

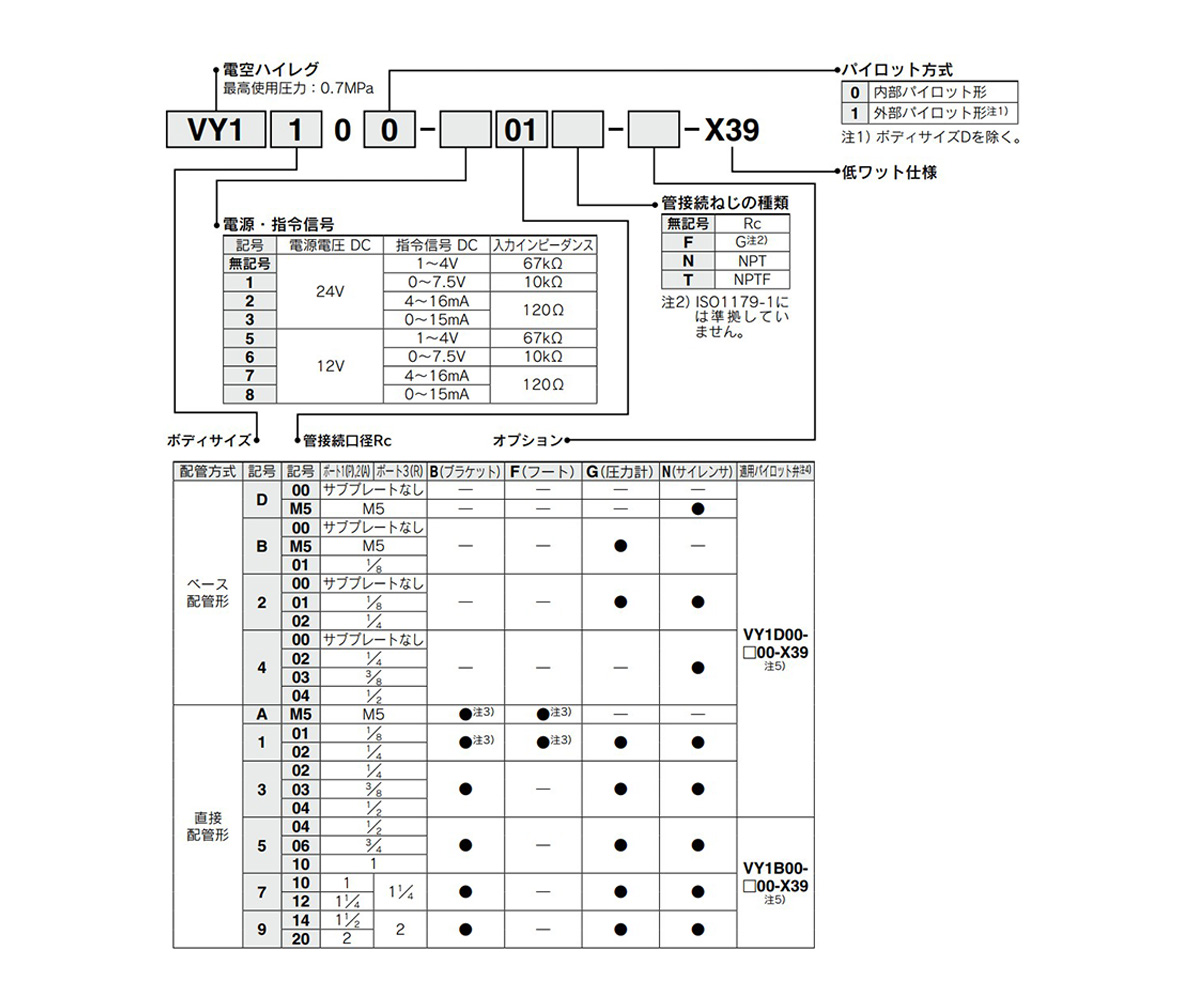

Model Number Notation (Made-to-Order Specifications)

Made-to-order specifications: model number example

- *Note 3) Only the bracket or foot can be mounted. They cannot be mounted together.

- *Note 4) When the pilot valve is replaced, it may not satisfy characteristics such as accuracy. As such, be sure to check that the product works without problems under the operating conditions before using. If the manufacturer is asked to repair the product, the manufacturer will perform an inspection to confirm the characteristics.

- *Note 5) The □ in the applicable pilot valve part number designates the power source / command signal.

Standard (Standard Specification)

| Model | VY1D00 | VY1A0 (0 to 1) |

VY1B0 (0 to 1) |

VY110 (0 to 1) |

VY120 (0 to 1) |

VY130 (0 to 1) |

VY140 (0 to 1) |

VY150 (0 to 1) |

VY170 (0 to 1) |

VY190 (0 to 1) |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Piping connection port diameter | Port | M5 | M5 | M5 | 01 | 01 | 02 | 01 | 02 | 02 | 03 | 04 | 02 | 03 | 04 | 04 | 06 | 10 | 10 | 12 | 14 | 20 |

| 1(P) | M5 | M5 | M5 | 1/8 | 1/8 | 1/4 | 1/8 | 1/4 | 1/4 | 3/8 | 1/2 | 1/4 | 3/8 | 1/2 | 1/2 | 3/4 | 1 | 1 | 1 1/4 | 1 1/2 | 2 | |

| 2(A) | ||||||||||||||||||||||

| 3(R) | 1 1/4 | 2 | ||||||||||||||||||||

| Weight (kg) Note 1) | 0.11 | 0.16 | 0.19 | 0.25 | 0.35 | 0.55 | 0.75 | 1.5 | 2 | 4 | ||||||||||||

| Hysteresis Note 2) | 0.009 MPa | 0.023 MPa | 0.027 MPa | 0.045 MPa | ||||||||||||||||||

| Sensitivity Note 2) | 0.005 MPa | 0.009 MPa | 0.014 MPa | 0.018 MPa | ||||||||||||||||||

| Repeatability Note 2) | ±0.005 MPa | ±0.009 MPa | ±0.009 MPa | ±0.018 MPa | ||||||||||||||||||

| Response time Note 2) | 10 ms | 30 ms | ||||||||||||||||||||

| Applicable fluids | Air | |||||||||||||||||||||

| Ambient temperature and working fluid temperature | 0 to +50°C (no condensation) | |||||||||||||||||||||

| Maximum operating pressure | 0.9 MPa | |||||||||||||||||||||

| Set pressure range | 0.05 to 0.84 MPa (at supply pressure of 0.9 MPa) | |||||||||||||||||||||

| External pilot pressure | – (Direct operated) | Set pressure +0.04 MPa to 0.9 MPa (for VY1□01) | ||||||||||||||||||||

| Command signal Note 3) | 1 to 5 V DC, 0 to 10 V DC, 4 to 20 mA DC, 0 to 20 mA DC | |||||||||||||||||||||

| Power supply | 12 V DC ±10%, 24 V DC ±10%, 1.8 W or less | |||||||||||||||||||||

| Method of electrical entry of lead wire | DIN terminal | |||||||||||||||||||||

| Compatible cable | Cable outer diameter ø4 to 6.5 (outer diameter 4 to 6.5 mm) | |||||||||||||||||||||

| Bleed amount (pilot EXH port) | When not operating: zero, When operating: 10 L/min (ANR) (at supply pressure of 0.9 MPa) | |||||||||||||||||||||

| Installation orientation | Free | |||||||||||||||||||||

| Lubrication | Not required Note 4) | |||||||||||||||||||||

- *Note 1) The weight of the base piping type (sizes D, B, 2, 4) is indicated for specifications with a subplate.

- *Note 2) All values indicated for the characteristics are the maximum values.

- *Note 3) Cut off the command signal when pressure control on the secondary (outlet) side is not required, such as when the line is temporarily halted, etc.

- *Note 4) To lubricate the secondary (outlet) side of VY, use VY as an external pilot. Avoid lubrication to the pilot air.

- *Note 5) The non-lubricated specification is not applicable to these models.

- *Note 6) The service life is approximately 4,000 to 5,000 operating hours (when using AF + AFM).

This may be approx. 3,000 hours with ultra-dry air (dew point -40°C equivalent).

Specifications (Made-To-Order Specifications)

| Maximum operating pressure Note 6) | 0.7 MPa |

|---|---|

| Set pressure range | 0.05 to 0.66 MPa (at supply pressure of 0.7 MPa) |

| External pilot pressure | Set pressure +0.04 MPa to 0.7 MPa |

| Command signal Note 7) | 1 to 4 V DC, 0 to 7.5 V DC, 4 to 16 mA DC, 0 to 15 mA DC |

| Power supply | 12 V DC ±10%, 24 V DC ±10%, 0.8 W or less |

| Bleed amount (pilot EXH port) | When not operating: zero, When operating: 7 L/min (ANR) (at supply pressure of 0.7 MPa) |

- *Specifications other than those written below are the same as the standard specifications.

- *Note 6) Make sure the supply pressure stays below the maximum operating pressure.

Allowing the supply pressure to exceed the maximum operating pressure can cause abnormal leakage from the pressure valve and affect the set pressure. - *Note 7) Cut off the command signal when pressure control on the secondary (outlet) side is not required, such as when the line is temporarily halted, etc.

Structural Drawings

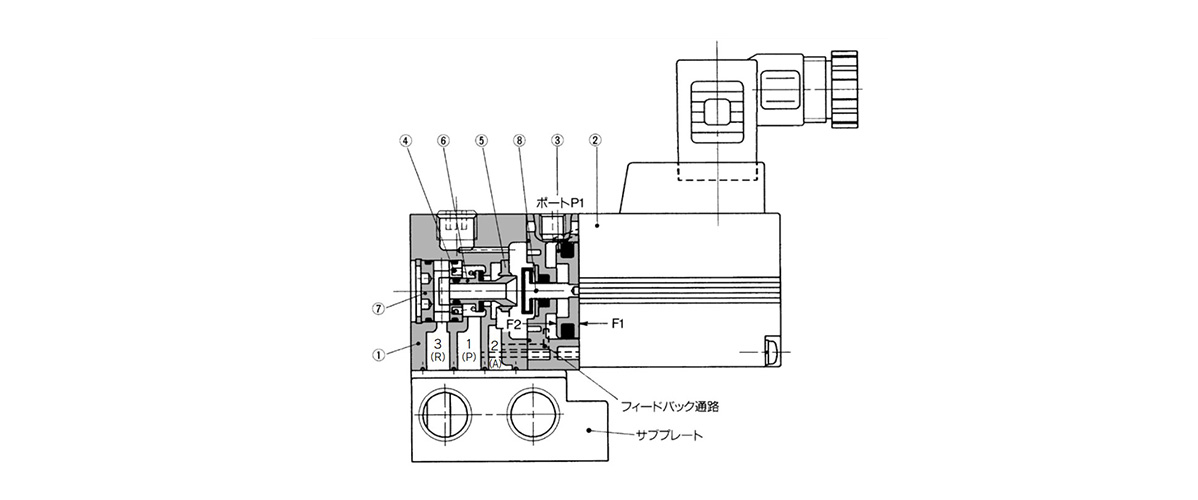

VY1A00/VY1A01, VY1B00/VY1B01 (Pilot Valve: VY1D00-□00)

VY1A00/VY1A01, VY1B00/VY1B01 (Pilot Valve: VY1D00-□00): structural drawings

Component Parts

| Number | Part name | Materials |

|---|---|---|

| 1 | Body | Zinc alloy, cast |

| 2 | Pilot valve assembly | – |

| 3 | Pressure regulating piston | Aluminum alloy |

| 4 | Spring | Stainless steel |

| 5 | Valve guide | Stainless steel |

| 6 | Valve | Aluminum alloy / rubber |

| 7 | Retainer | Aluminum alloy |

| 8 | Rod | Stainless steel / rubber |

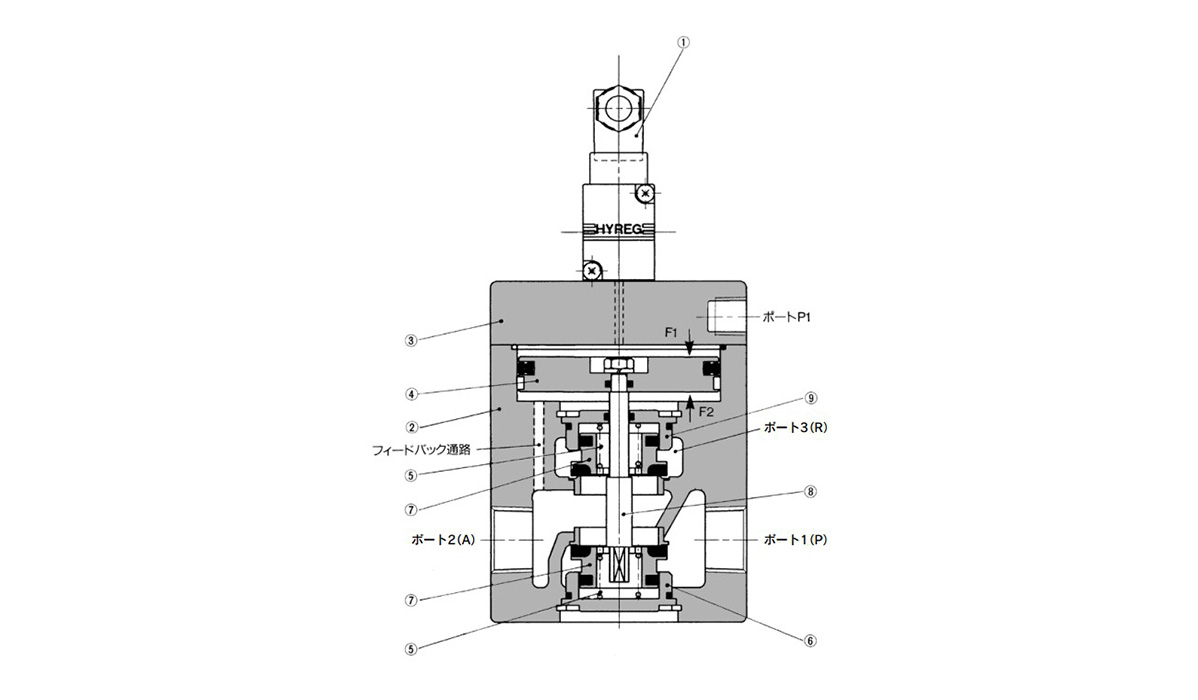

VY1100/VY1101, VY1200/VY1201, VY1300/VY1301, VY1400/VY1401 (Pilot Valve: VY1D00-□00), (Pilot Valve: VY1B00-□00), VY1500/VY1501, VY1700/VY1701, VY1900/VY1901

VY1100/VY1101, VY1200/VY1201, VY1300/VY1301, VY1400/VY1401 (Pilot valve: VY1D00-□00), (Pilot Valve: VY1B00-□00), VY1500/VY1501, VY1700/VY1701, VY1900/VY1901: structural drawings

Component Parts

| Number | Part name | Materials |

|---|---|---|

| 1 | Pilot valve assembly | – |

| 2 | Body | Aluminum alloy, cast |

| 3 | Cover | Aluminum alloy, cast |

| 4 | Pressure regulating piston | Aluminum alloy |

| 5 | Spring | Stainless steel |

| 6 | Valve guide | Aluminum alloy |

| 7 | Poppet valve | Aluminum alloy / rubber |

| 8 | Shaft | Stainless steel |

| 9 | Valve guide | Aluminum alloy |

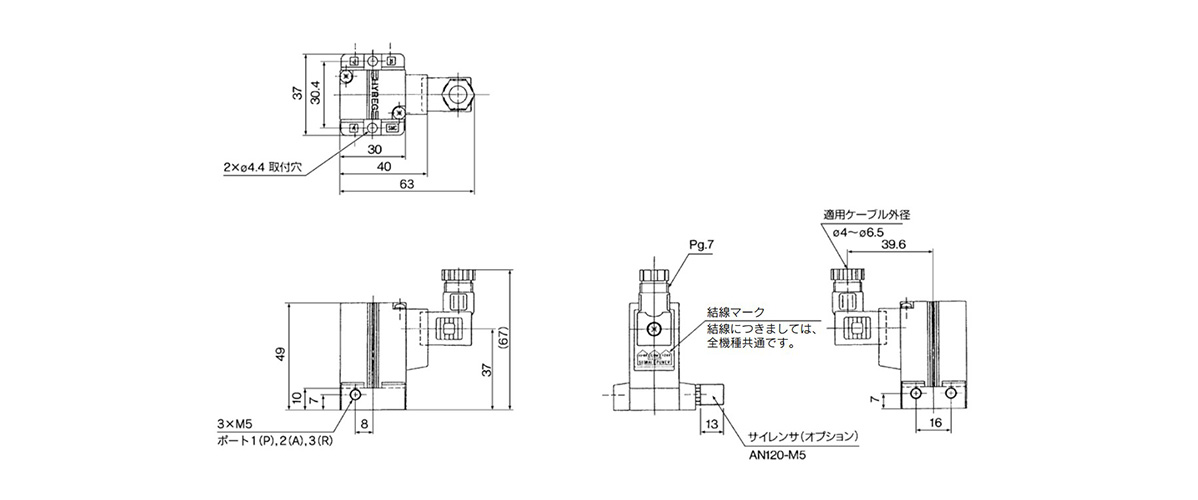

Electro-Pneumatic E-P HYREG VY1 Series: Dimensions Examples

(Unit: mm)

VY1D00 dimensional drawing

Basic Information

| Regulator, Pressure Boosting Valve | Regulator | Regulator Type | Electropneumatic | Applicable Fluid | Air |

|---|---|---|---|---|---|

| Shape | Standard | Operating Environment | Standard | Adverse Current Function | No |

VY1100-01-B

VY1100-01-BG

VY1100-01-BGN

VY1100-01-BGN-X39

VY1100-01-BN

VY1100-01-BN-X39

VY1100-01-F

VY1100-01-F-X39

VY1100-01-FG

VY1100-01-FG-X39

VY1100-01-FGN

VY1100-01-FN

VY1200-00

VY1200-00-G

VY1200-00-GN

VY1200-00-N

VY1200-00-X39

VY1200-01

VY1200-01-G

VY1200-01-G-X39

VY1200-01-GN

VY1200-01-GN-X39

VY1300-02

VY1300-02-B

VY1300-02-BG

VY1300-02-BGN

VY1300-02-BGN-X39

VY1300-02-BN

VY1300-02-GN

VY1300-02-N

VY1300-02-X39

VY1300-02F

VY1400-00-N

VY1400-02

VY1400-03

VY1400-03-N

VY1400-03N

VY1400-04

VY1400-04-N

VY1400-04F

VY1400-04N

VY1400-100

VY1500-04

VY1500-04-B

VY1500-04-BG

VY1500-04-BGN

VY1500-04-BN

VY1500-04-GN

VY1500-04-N

VY1500-04-X39

VY1500-04F

VY1500-04N

VY1500-06

VY1500-06-B

VY1500-06-BG

VY1500-06-BGN

VY1700-10

VY1700-10-BG

VY1700-10-BGN

VY1700-10-GN

VY1700-10-N

VY1700-10-N-X39

VY1700-10F

VY1700-10N

VY1700-10N-BG

VY1700-12

VY1700-12-B

VY1900-14-BG

VY1900-14-BN

VY1900-14-GN

VY1900-14-GN-X39

VY1900-14-N

VY1900-14-X39

VY1900-14F

VY1900-14F-BGN

VY1900-14F-GN

VY1900-14N

VY1900-14N-B

VY1900-20

VY1900-20-BGN

VY1900-20-GN

VY1900-20-N

VY1A00-1M5

VY1A00-1M5-B

VY1A00-1M5-F

VY1A00-2M5

VY1A00-2M5-B

VY1A00-2M5-F

VY1A00-5M5

VY1A00-5M5-B

VY1A00-5M5-F

VY1A00-6M5

VY1A00-6M5-B

VY1A00-6M5-B-X39

VY1A00-6M5-F

VY1A00-8M5-B

VY1A00-M5

VY1A00-M5-B

VY1A00-M5-F

VY1A01-1M5

VY1B00-00-G

VY1B00-00-X39

VY1B00-01

VY1B00-01-G

VY1B00-01F

VY1B00-01N

VY1B00-1M5

VY1B00-2M5-G

VY1B00-6M5

VY1B00-100

VY1B00-100-G

VY1B00-100-X39

VY1B00-101

VY1B00-101-G

VY1B00-101F

VY1B00-101N

VY1B00-200

VY1B00-200-X39

VY1D00-00

VY1D00-00-X39

VY1D00-1M5

VY1D00-1M5-N

VY1D00-2M5

VY1D00-5M5

VY1D00-6M5

VY1D00-6M5-N

VY1D00-7M5

VY1D00-100

VY1D00-100-X39

VY1D00-200

VY1D00-200-X39

VY1D00-300

VY1D00-500

VY1D00-600

VY1D00-800

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.

👉 Công ty 𝐌𝐞𝐝𝐢𝐧 hỗ trợ:

![]() 𝑇𝑢̛ 𝑣𝑎̂́𝑛 𝑔𝑖𝑎̉𝑖 𝑝ℎ𝑎́𝑝 𝑡𝑜̂́𝑖 𝑢̛𝑢

𝑇𝑢̛ 𝑣𝑎̂́𝑛 𝑔𝑖𝑎̉𝑖 𝑝ℎ𝑎́𝑝 𝑡𝑜̂́𝑖 𝑢̛𝑢

![]() 𝐶𝑜́ 𝑠𝑎̆̃𝑛 𝑠𝑎̉𝑛 𝑝ℎ𝑎̂̉𝑚 𝑑𝑢̀𝑛𝑔 𝑡ℎ𝑢̛̉

𝐶𝑜́ 𝑠𝑎̆̃𝑛 𝑠𝑎̉𝑛 𝑝ℎ𝑎̂̉𝑚 𝑑𝑢̀𝑛𝑔 𝑡ℎ𝑢̛̉

![]() 𝐻𝑜̂̃ 𝑡𝑟𝑜̛̣ 𝑡𝑒𝑠𝑡 𝑡𝑎̣̂𝑛 𝑛𝑜̛𝑖

𝐻𝑜̂̃ 𝑡𝑟𝑜̛̣ 𝑡𝑒𝑠𝑡 𝑡𝑎̣̂𝑛 𝑛𝑜̛𝑖

👉 Nếu bạn có bất kỳ yêu cầu nào, vui lòng liên hệ với chúng tôi.

☎️ Hotline: 0902782082

🌐 Website: https://www.medin.com.vn/

- 𝐕𝐏 𝐇𝐨 𝐂𝐡𝐢 𝐌𝐢𝐧𝐡: 01 Đường 410C, Phước Long A, Tp. Thủ Đức

- 𝐇𝐚 𝐍𝐨𝐢 𝐛𝐫𝐚𝐧𝐜𝐡: 562 Nguyễn Văn Cừ, Long Biên, Hà Nội

- 𝐃𝐚 𝐍𝐚𝐧𝐠 𝐛𝐫𝐚𝐧𝐜𝐡: 63 Phan Đăng Lưu, Hải Châu, Đà Nẵng