ARM1000/2000 Series Manifold Regulator – Bộ Chỉnh Áp Khí Nén SMC

Product Description

ARM1000/2000 Series Manifold Regulator – Bộ Chỉnh Áp Khí Nén SMC

Manifold regulator with 4 connection methods.

[Features]

·Compact pressure gauge ø15 (diameter 15 mm)

·Standard specifications with backflow function

· Space saving

Download

ARM1000/2000 Series Manifold Regulator Specifications – Bộ Chỉnh Áp Khí Nén SMC

ARM2000-4B2 external appearance

ARM2000-4A2-01G external appearance

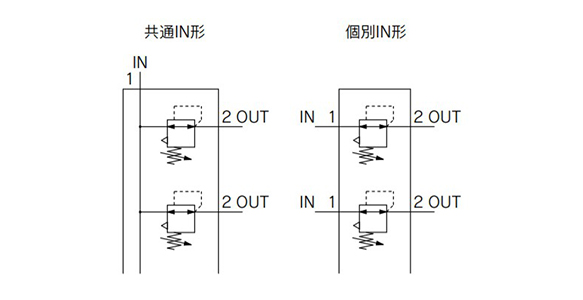

Common IN (left) / individual IN (right) JIS symbols

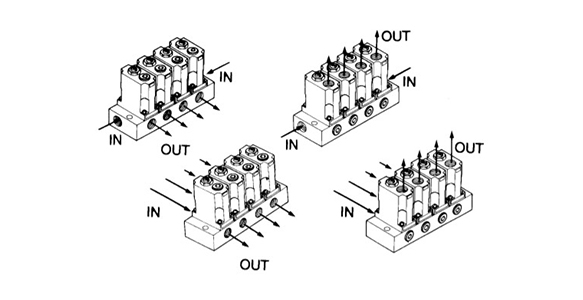

Conceptual diagram of connection variants

| Ambient and fluid temperature | -5 to +60°C (no freezing) |

|---|---|

| Fluid | Air |

| Cracking pressure (valve) | 0.02 MPa |

| Structure | Relieving type |

Port Size / Weight

| Model | Piping specifications | Connection port size | Weight (g) | ||

|---|---|---|---|---|---|

| IN side | OUT side | Total weight (n: stations) | Regulator (except manifold) | ||

| ARM1000 | Common IN | 1/8 | 1/8 | (80 × n) + 23 | 57 |

| Individual IN | 1/8 | 1/8 | (79 × n) +25 | ||

| ARM2000 | Common IN | 1/4 | 1/8 | (188 × n) +43 | 136 |

| Individual IN | 1/8 | 1/8 | (187 × n) +45 | ||

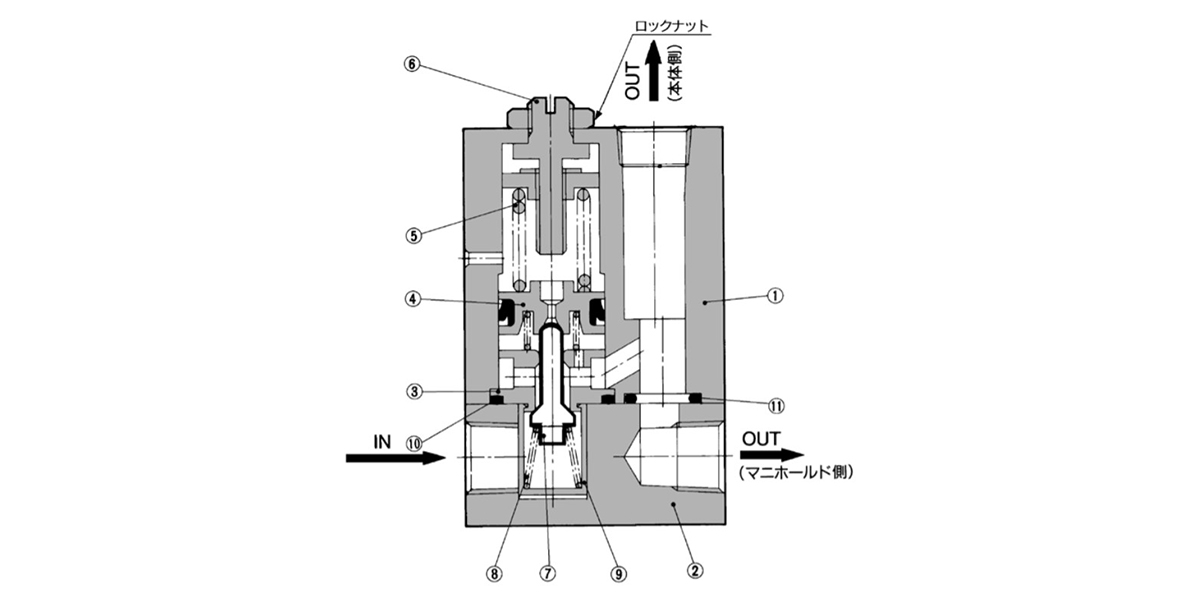

Diagram (Individual IN)

Individual IN Diagram

| Number | Part name | Material | Note |

|---|---|---|---|

| 1 | Main body | Die-cast aluminum | Chromate treatment |

| 2 | Manifolds | Aluminum alloy | Chromate treatment |

| 3 | Valve guide | Brass | – |

| 4 | Piston | Brass | – |

| 5 | Pressure regulator spring | Steel wire | Zinc chromate |

| 6 | Adjusting screw | Structural steel | Electroless nickel plating |

| Number | Part name | Material |

|---|---|---|

| 7 | Valve | Brass, HNBR |

| 8 | Valve spring | Stainless steel |

| 9 | Valve retainer | Polyacetal |

| 10 | O-ring | NBR |

| 11 | O-ring | NBR |

Setting

- 1.Make sure to check the inlet pressure before setting the outlet pressure. Turning the pressure adjustment handle clockwise increases the outlet pressure and turning it counterclockwise decreases the pressure. (To set the pressure, do so in the direction of pressure)

- 2.The outlet pressure range must be 85% or less than the inlet pressure.

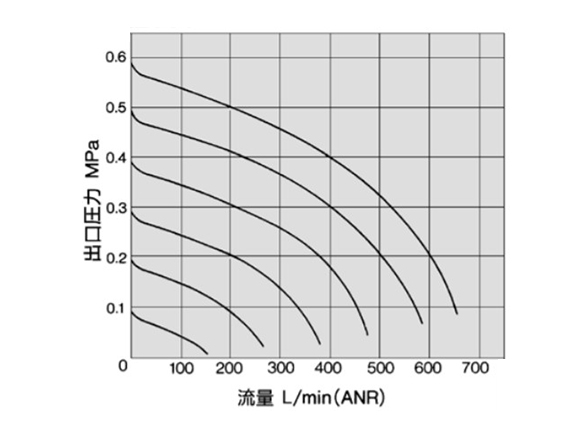

Flow Characteristics (Representative Values)

Conditions: inlet pressure = 0.7 MPa

ARM1000 flow rate characteristics graph

ARM2000 flow rate characteristics graph

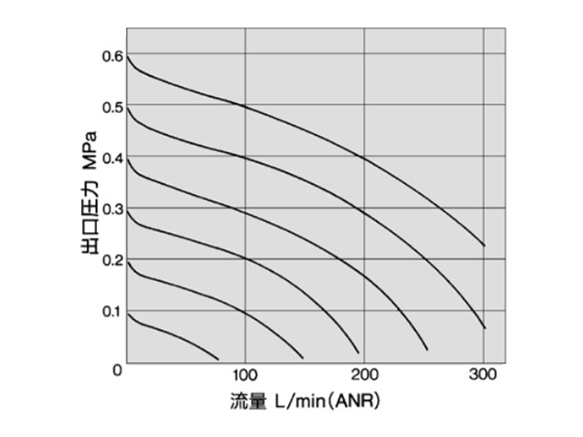

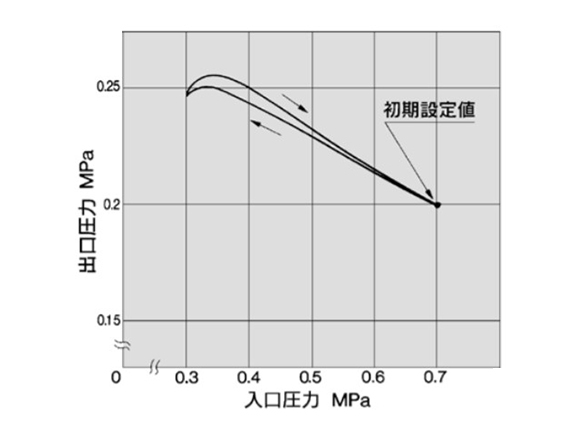

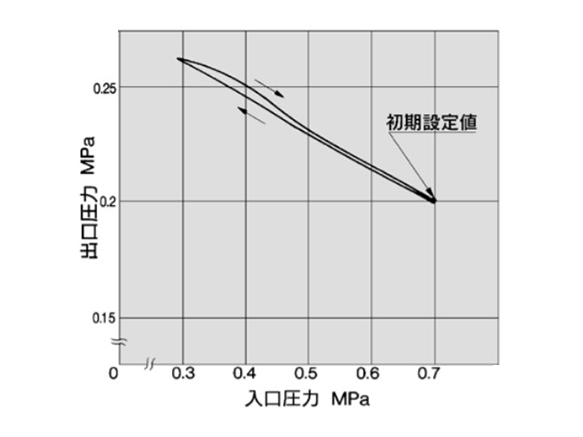

Pressure Characteristics (Representative Values)

Conditions (initial settings): inlet pressure 0.7 MPa, outlet pressure 0.2 MPa, flow rate 10 L/min (ANR)

ARM1000 pressure characteristics graph

ARM2000 pressure characteristics graph

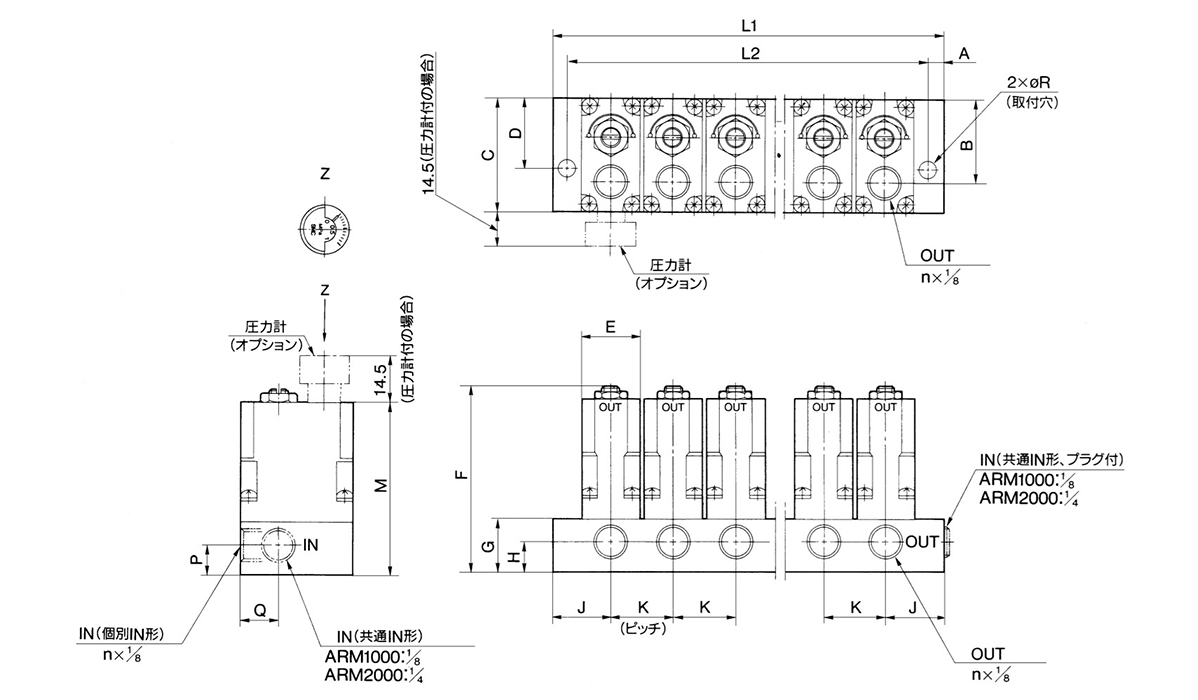

Dimensions

(Unit: mm)

ARM1000/2000 Series dimensional drawing

External Dimensions Table

(Unit: mm)

| Model | Symbol | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | J | K | M | P | Q | R | |

| ARM1000 | 4.5 | 25 | 34 | 21 | 18 | 56 | 16 | 9 | 18 | 19 | 52 | 9 | 11.5 | 4.8 |

| ARM2000 | 4.5 | 34.5 | 43 | 28 | 27 | 70 | 20 | 11.5 | 24 | 28 | 66 | 11.5 | 16.5 | 4.8 |

Dimensions by the Number of Stations

(Unit: mm)

| Model | Symbol | Manifold stations (n) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | ||

| ARM1000 | L1 | 36 | 55 | 74 | 93 | 112 | 131 | 150 | 169 | 188 | 207 |

| L2 | 27 | 46 | 65 | 84 | 103 | 122 | 141 | 160 | 179 | 198 | |

| ARM2000 | L1 | 48 | 76 | 104 | 132 | 160 | 188 | 216 | 244 | 272 | 300 |

| L2 | 39 | 67 | 95 | 123 | 151 | 179 | 207 | 235 | 263 | 291 | |

Precautions

Mounting/Adjustment

- *In the case of the common IN type, supply pressure from the two IN ports from both ends. Failure to observe this procedure could lead to an excessive pressure drop.

- *Release the lock to adjust the pressure. After the adjustment, engage the lock. Failure to observe this procedure could damage the handle or cause the outlet pressure to fluctuate.

Lock operating method

Loosen the handle locking nut to release the lock, and tighten it to lock it. - *The attached reverse flow mechanism is placed between the electromagnetic valve and actuator and can be used as a check regulator.

Maintenance

- *Make sure to perform a periodic inspection of the pressure gauge when it is used by installing it between a solenoid valve and an actuator, etc. Because of the possibility of creating sudden pressure fluctuations, the durability of the product could be shortened. Under certain circumstances, the use of an electronic type pressure gauge is recommended.

Other precautions

- *Be sure to read the safety precautions as well as the common precautions in the manufacturer’s catalog before use.

- *The images for this product are representative images. *The product shown may differ from the actual product.

- *See the manufacturer’s catalog for information other than the above.

Basic Information

| Regulator, Pressure Boosting Valve | Regulator | Regulator Type | Manifold shaped | Applicable Fluid | Air |

|---|---|---|---|---|---|

| Shape | Standard | Operating Environment | Standard | Exhaust Mechanism | Relief |

| Adverse Current Function | Presence | Operating Pressure Range(MPa) | null::0.8 | Control Side, Connection Dia. | 1/8 |

ARM1000-1A1-01-1

ARM1000-1A1-01G

ARM1000-1A1-01G-1

ARM1000-1A1-N01G

ARM1000-1A1-N01G-1

ARM1000-2A1-01

ARM1000-2A1-01-1

ARM1000-2A1-01G

ARM1000-2A1-01G-1

ARM1000-2A1-N01

ARM1000-2A1-N01G

ARM1000-2A1-N01G-1

ARM1000-3A1-01

ARM1000-3A1-01G

ARM1000-3A1-01G-1

ARM1000-3A1-N01G

ARM1000-3A1-N01G-1

ARM1000-4A1-01

ARM1000-1A2-01

ARM1000-1A2-01G

ARM1000-1A2-01G-1

ARM1000-2A2-01

ARM1000-2A2-01G

ARM1000-2A2-01G-1

ARM1000-3A2-01

ARM1000-3A2-01G

ARM1000-3A2-01G-1

ARM1000-3A2-N01

ARM1000-4A2-01

ARM1000-4A2-01G

ARM1000-4A2-01G-1

ARM1000-4A2-N01G

ARM1000-4A2-N01G-1

ARM1000-5A2-01

ARM1000-5A2-01G

ARM1000-1B1-01-1

ARM1000-1B1-01G

ARM1000-1B1-01G-1

ARM1000-1B1-N01

ARM1000-1B1-N01G

ARM1000-2B1-01

ARM1000-2B1-01G

ARM1000-2B1-01G-1

ARM1000-3B1-01

ARM1000-3B1-01-1

ARM1000-3B1-01G

ARM1000-3B1-01G-1

ARM1000-4B1-01

ARM1000-4B1-01-1

ARM1000-1B2-01

ARM1000-1B2-01G

ARM1000-1B2-01G-1

ARM1000-1B2-N01G

ARM1000-2B2-01

ARM1000-2B2-01-1

ARM1000-2B2-01G

ARM1000-2B2-01G-1

ARM1000-3B2-01

ARM1000-3B2-01-1

ARM1000-3B2-01G

ARM1000-3B2-01G-1

ARM1000-4B2-01

ARM2000-1A1-01

ARM2000-1A1-01G

ARM2000-1A1-01G-1

ARM2000-1A1-N01

ARM2000-2A1-01

ARM2000-2A1-01-1

ARM2000-2A1-01G

ARM2000-2A1-01G-1

ARM2000-2A1-N01

ARM2000-3A1-01

ARM2000-3A1-01-1

ARM2000-1A2-01G

ARM2000-2A2-01

ARM2000-2A2-01G

ARM2000-2A2-01G-1

ARM2000-2A2-N01G

ARM2000-2A2-N01G-1

ARM2000-3A2-01

ARM2000-3A2-01G

ARM2000-3A2-01G-1

ARM2000-4A2-01

ARM2000-4A2-01G

ARM2000-1B1-01

ARM2000-1B1-01-1

ARM2000-1B1-01G

ARM2000-1B1-01G-1

ARM2000-1B1-N01

ARM2000-2B1-01

ARM2000-2B1-01G

ARM2000-2B1-01G-1

ARM2000-2B1-N01

ARM2000-3B1-01

ARM2000-3B1-01G

ARM2000-3B1-01G-1

ARM2000-3B1-N01-1

ARM2000-1B2-01

ARM2000-1B2-01G

ARM2000-1B2-01G-1

ARM2000-2B2-01

ARM2000-2B2-01G

ARM2000-2B2-01G-1

ARM2000-3B2-01

ARM2000-3B2-01G

ARM2000-4B2-01

ARM2000-4B2-01G

ARM2000-4B2-01G-1

ARM2000-5B2-01

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.

👉 Công ty 𝐌𝐞𝐝𝐢𝐧 hỗ trợ:

![]() 𝑇𝑢̛ 𝑣𝑎̂́𝑛 𝑔𝑖𝑎̉𝑖 𝑝ℎ𝑎́𝑝 𝑡𝑜̂́𝑖 𝑢̛𝑢

𝑇𝑢̛ 𝑣𝑎̂́𝑛 𝑔𝑖𝑎̉𝑖 𝑝ℎ𝑎́𝑝 𝑡𝑜̂́𝑖 𝑢̛𝑢

![]() 𝐶𝑜́ 𝑠𝑎̆̃𝑛 𝑠𝑎̉𝑛 𝑝ℎ𝑎̂̉𝑚 𝑑𝑢̀𝑛𝑔 𝑡ℎ𝑢̛̉

𝐶𝑜́ 𝑠𝑎̆̃𝑛 𝑠𝑎̉𝑛 𝑝ℎ𝑎̂̉𝑚 𝑑𝑢̀𝑛𝑔 𝑡ℎ𝑢̛̉

![]() 𝐻𝑜̂̃ 𝑡𝑟𝑜̛̣ 𝑡𝑒𝑠𝑡 𝑡𝑎̣̂𝑛 𝑛𝑜̛𝑖

𝐻𝑜̂̃ 𝑡𝑟𝑜̛̣ 𝑡𝑒𝑠𝑡 𝑡𝑎̣̂𝑛 𝑛𝑜̛𝑖

👉 Nếu bạn có bất kỳ yêu cầu nào, vui lòng liên hệ với chúng tôi.

☎️ Hotline: 0902782082

🌐 Website: https://www.medin.com.vn/

- 𝐕𝐏 𝐇𝐨 𝐂𝐡𝐢 𝐌𝐢𝐧𝐡: 01 Đường 410C, Phước Long A, Tp. Thủ Đức

- 𝐇𝐚 𝐍𝐨𝐢 𝐛𝐫𝐚𝐧𝐜𝐡: 562 Nguyễn Văn Cừ, Long Biên, Hà Nội

- 𝐃𝐚 𝐍𝐚𝐧𝐠 𝐛𝐫𝐚𝐧𝐜𝐡: 63 Phan Đăng Lưu, Hải Châu, Đà Nẵng