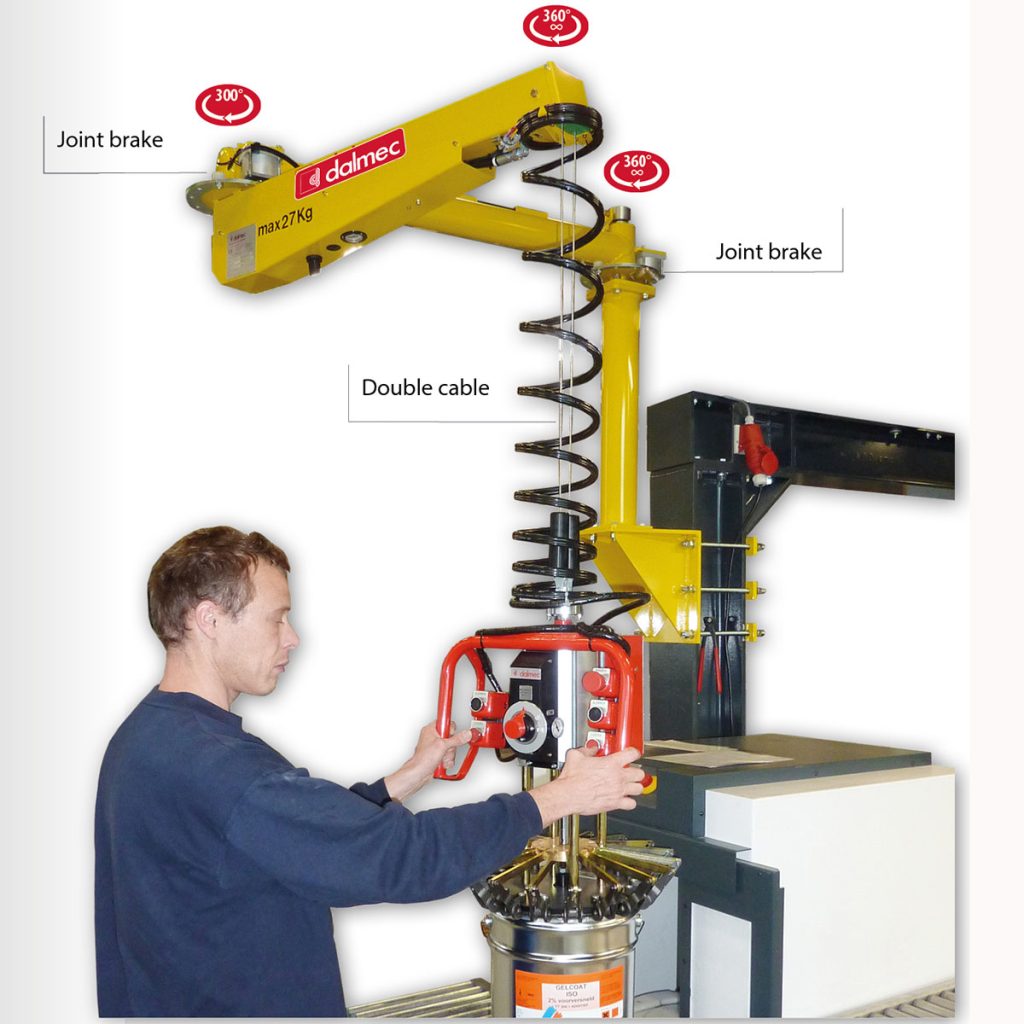

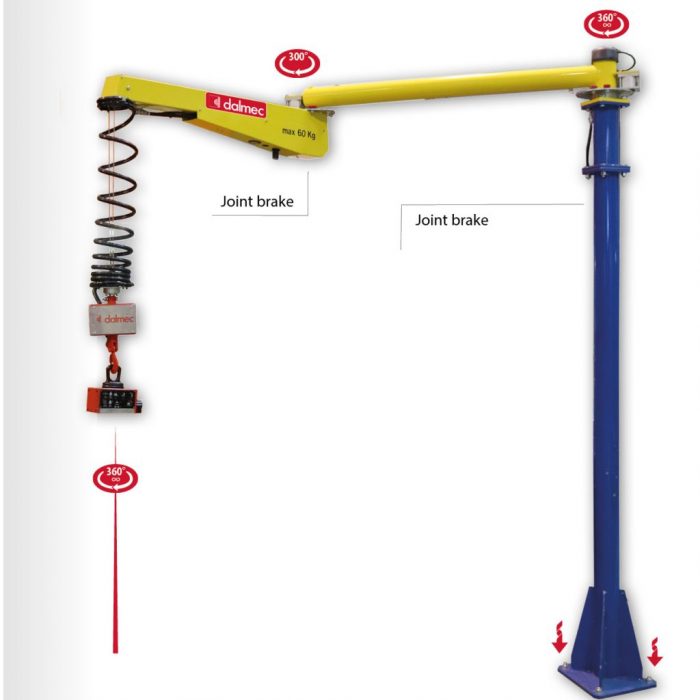

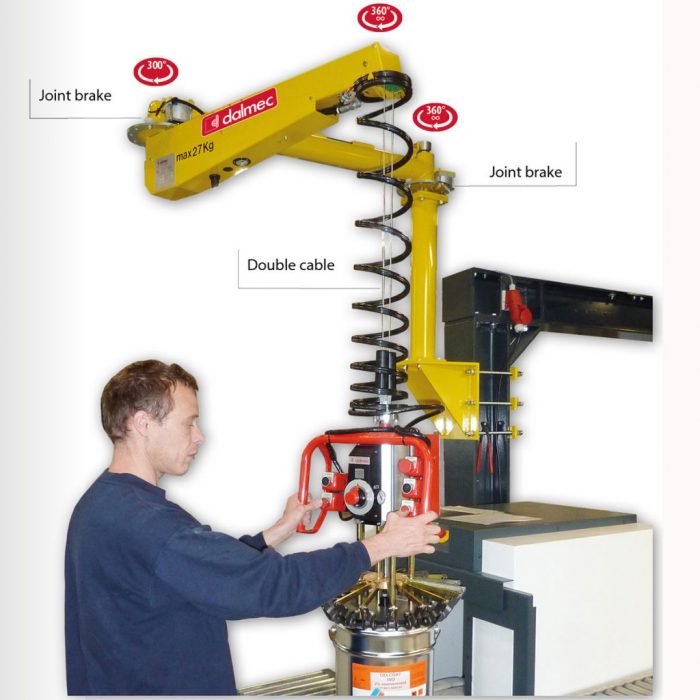

MANIPULATOR WITH DOUBLE CABLE POSIVEL PV

POSIVEL PV, generally realized with hook, can be equipped with simple gripping tools to allow the handling of light loads in a weightless condition in any direction. The particular double arm structure and medium joint makes it easy to handle and precise throughout the working area.

OPERATION

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied.

The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced.

The operator can change the load level applying a minimum force on the gripping tool or directly on the load.