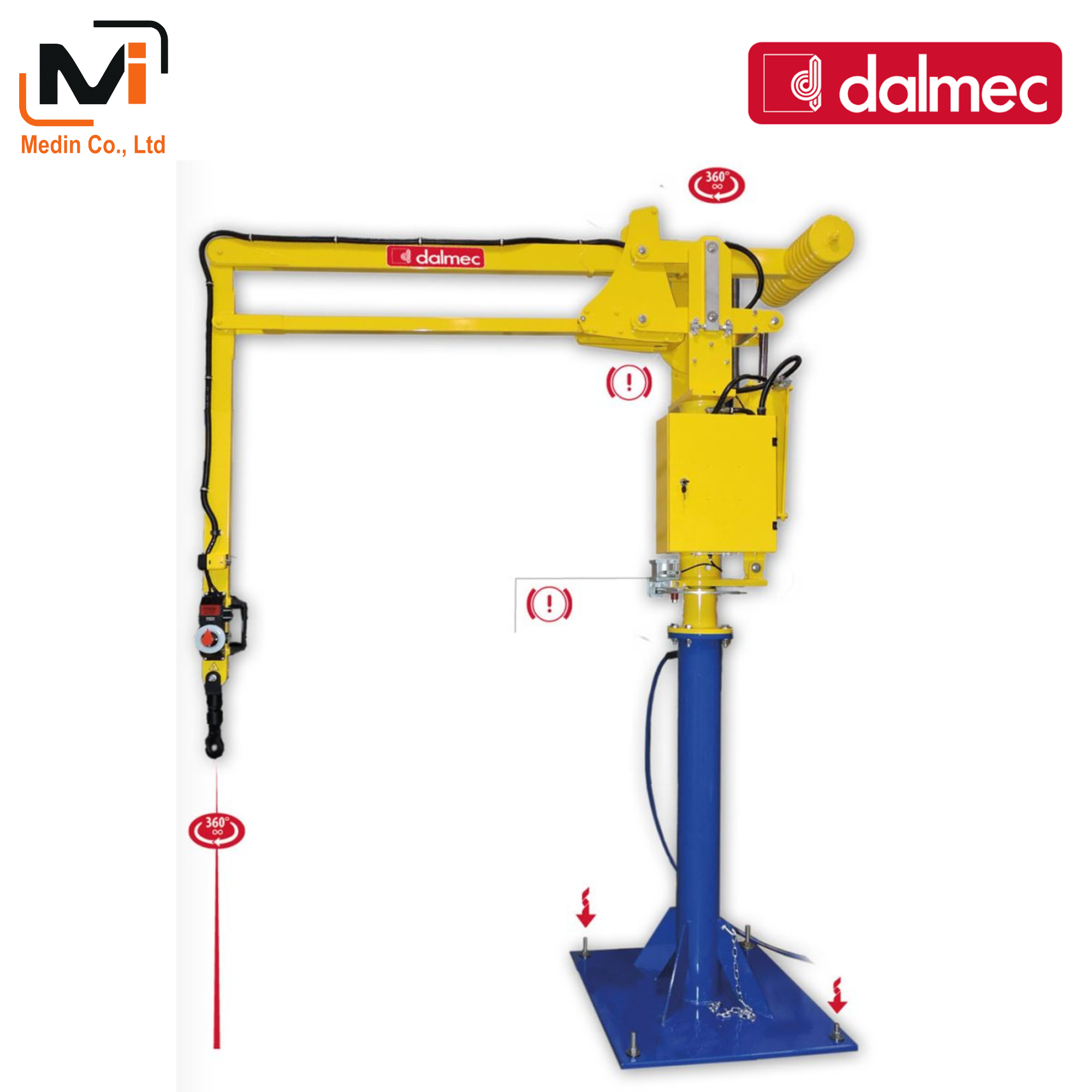

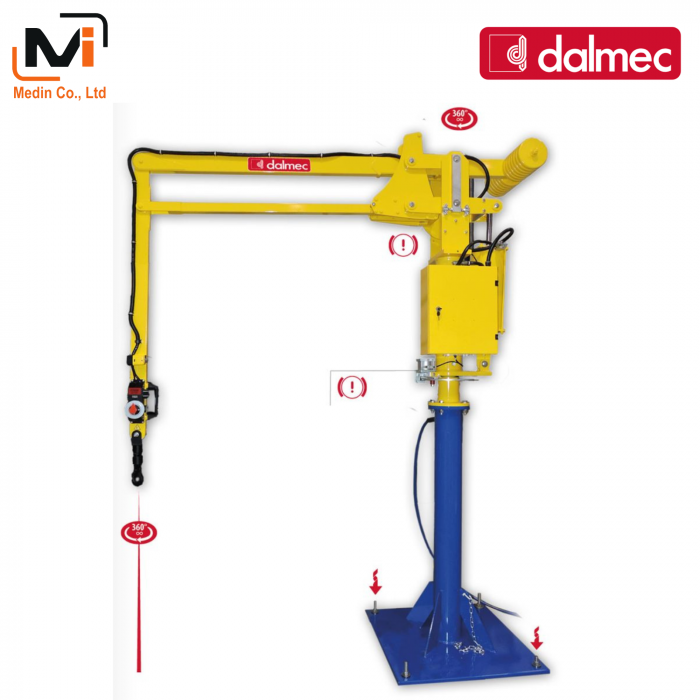

INDUSTRIAL MANIPULATOR PARTNER PS WITH ARTICULATED ARMS

The Manipulator PARTNER PS is a good working assistant for the operator who can work quickly, with precision and without any effort, in excellent ergonomic and safety conditions. Equipped with special gripping tools, it is particularly suitable to manually handle loads in a weightless condition in any direction.

OPERATING

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied. The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced. The operator can change the load level applying a minimum force on the gripping tool or directly on the load.