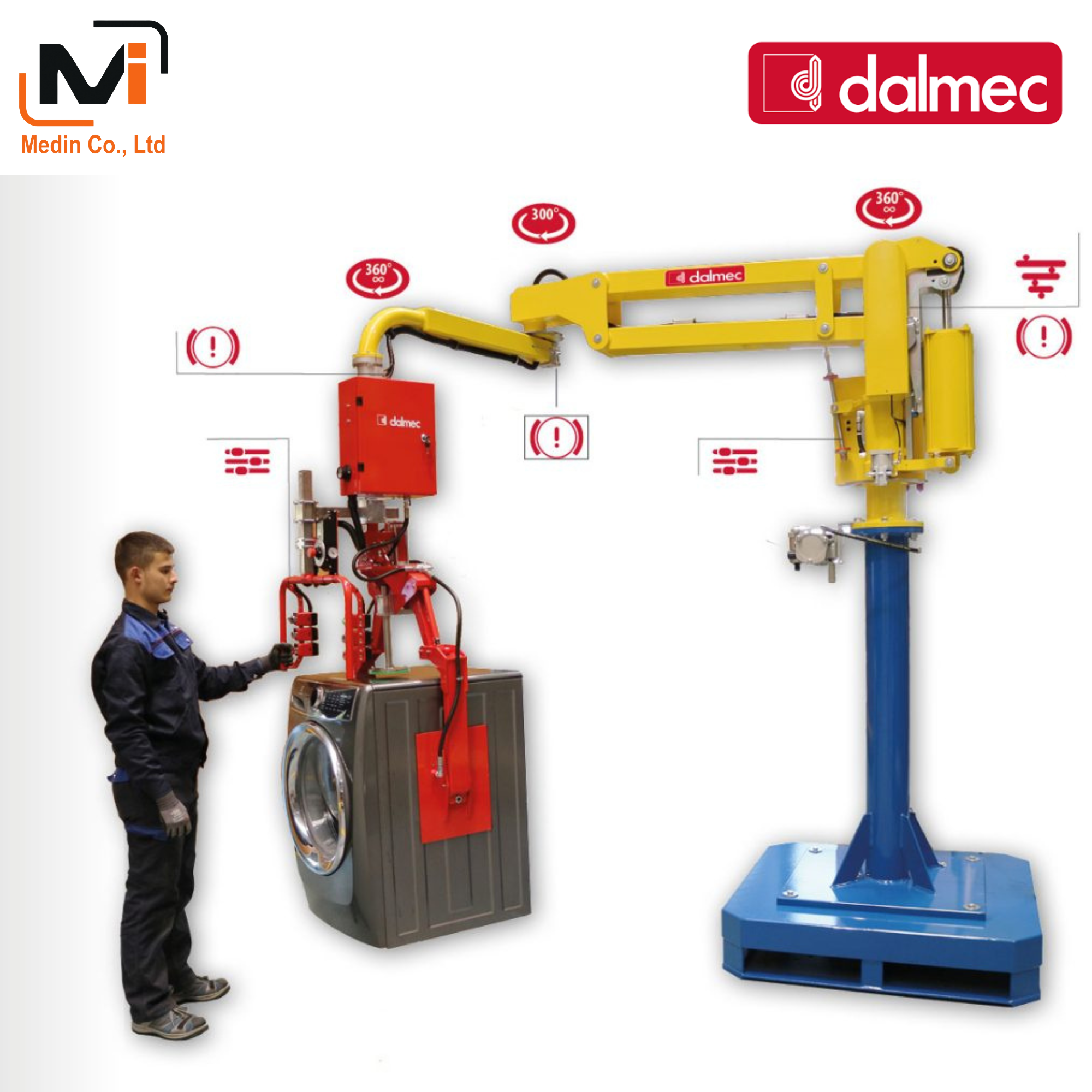

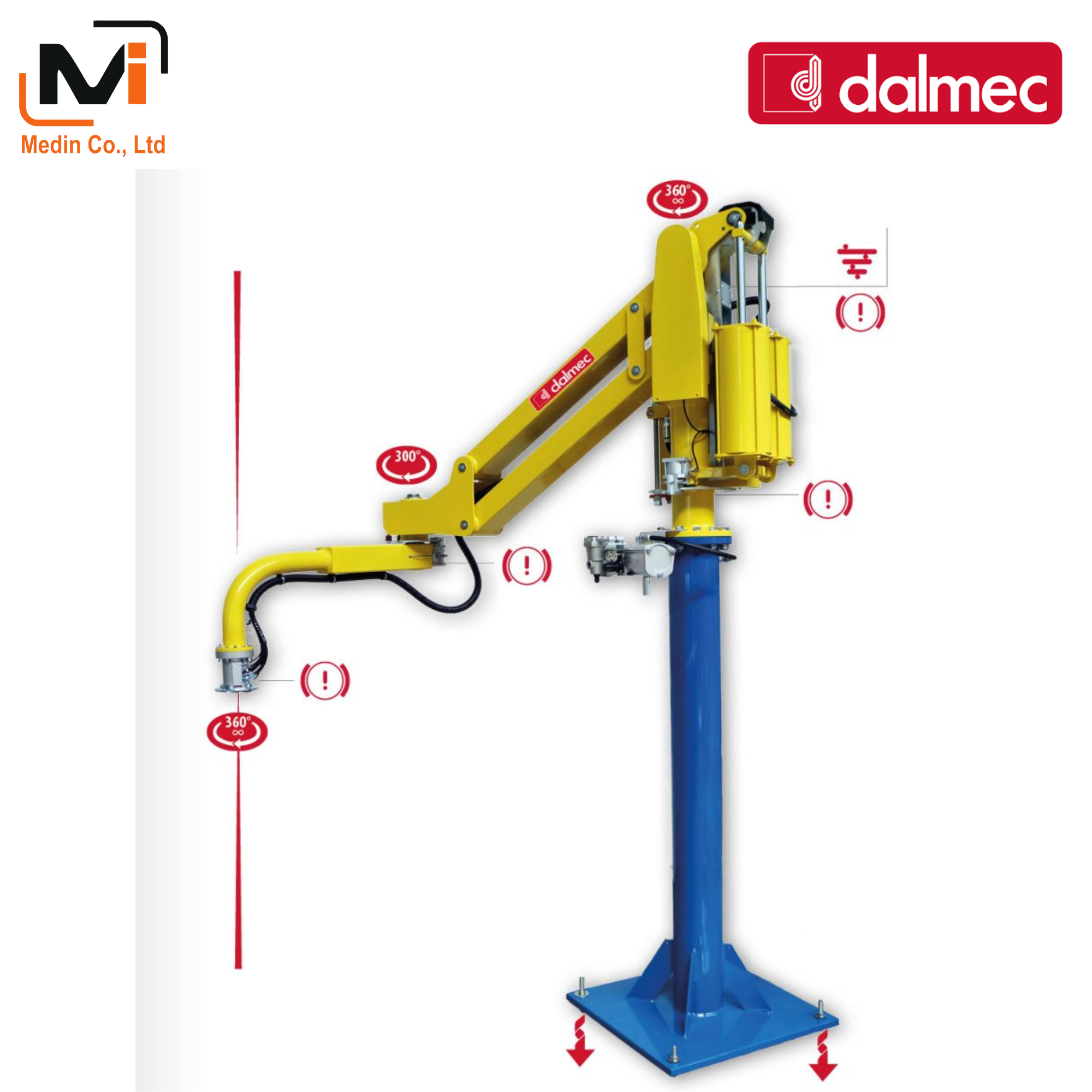

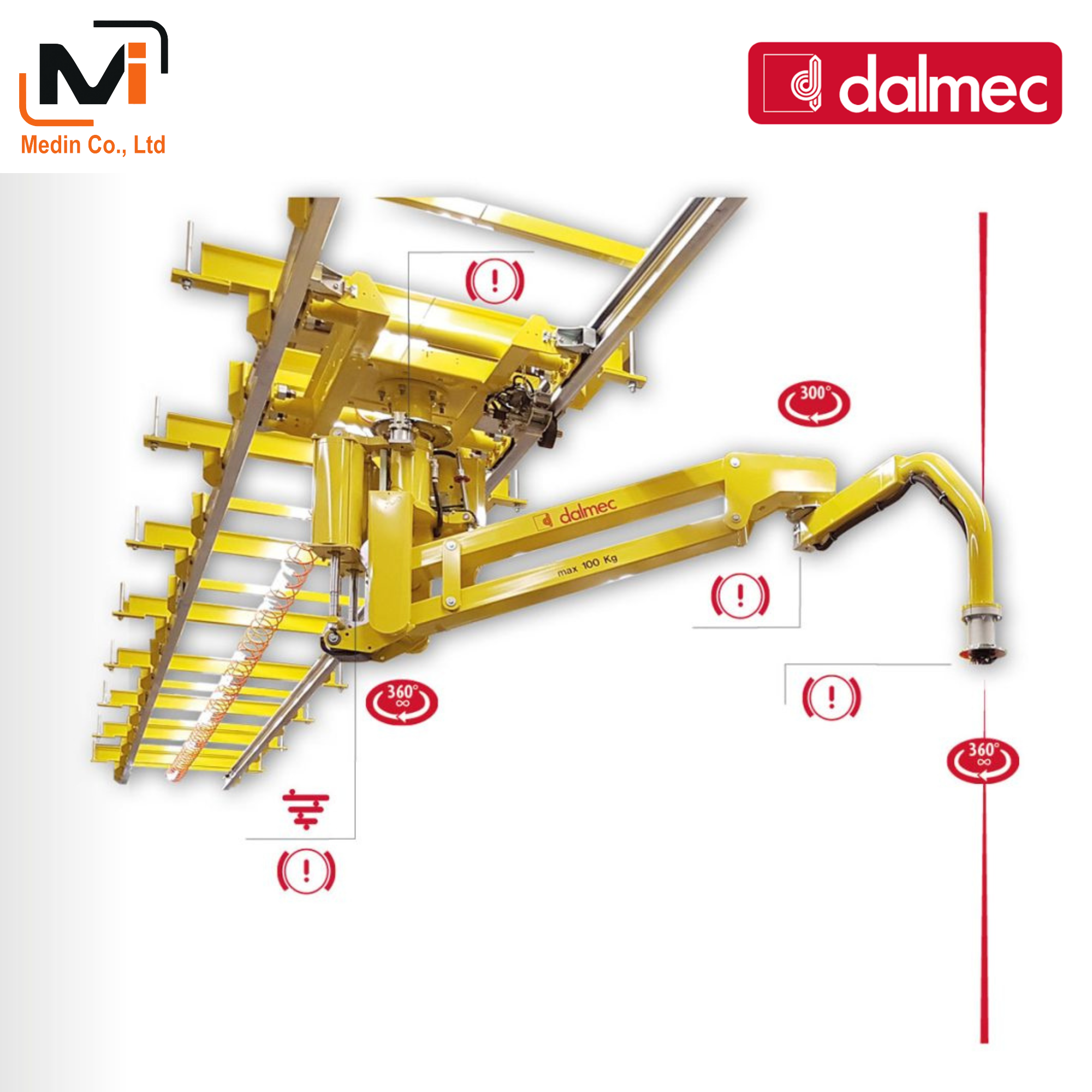

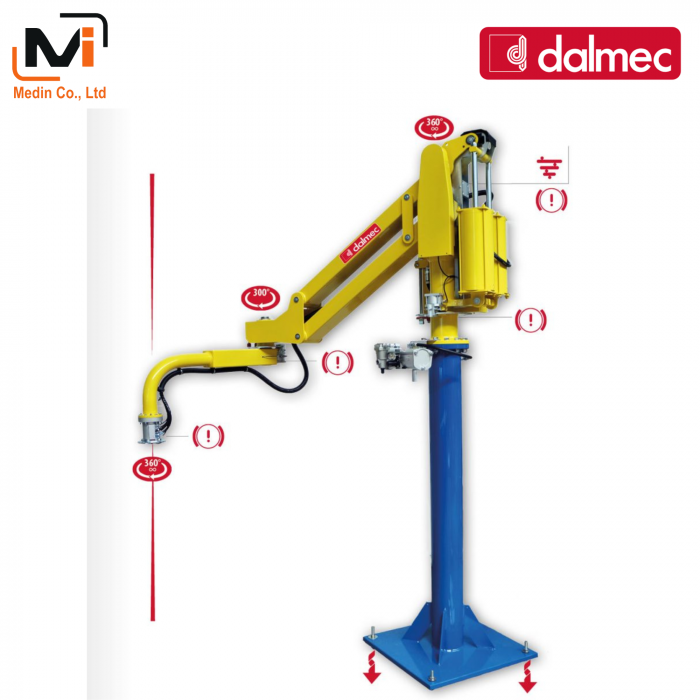

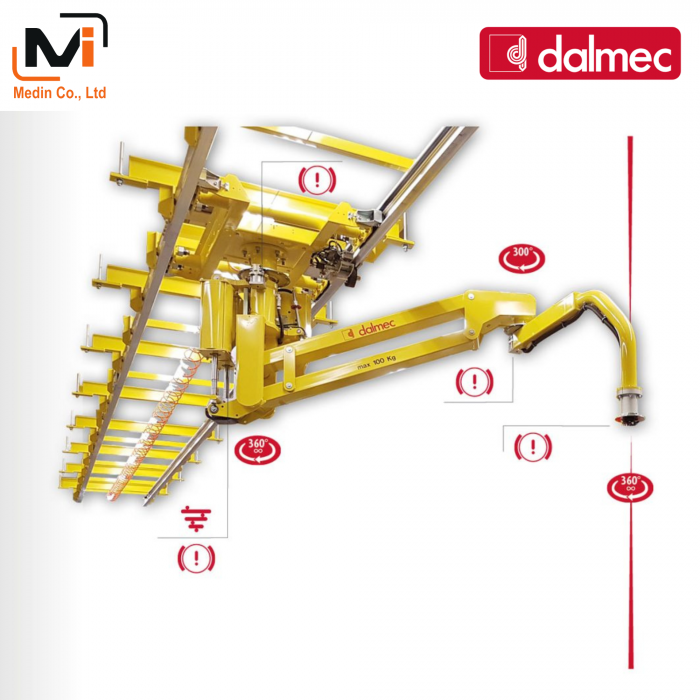

MANIPULATOR WITH ARTICULATED ARMS MAXIPARTNER EQUO ME

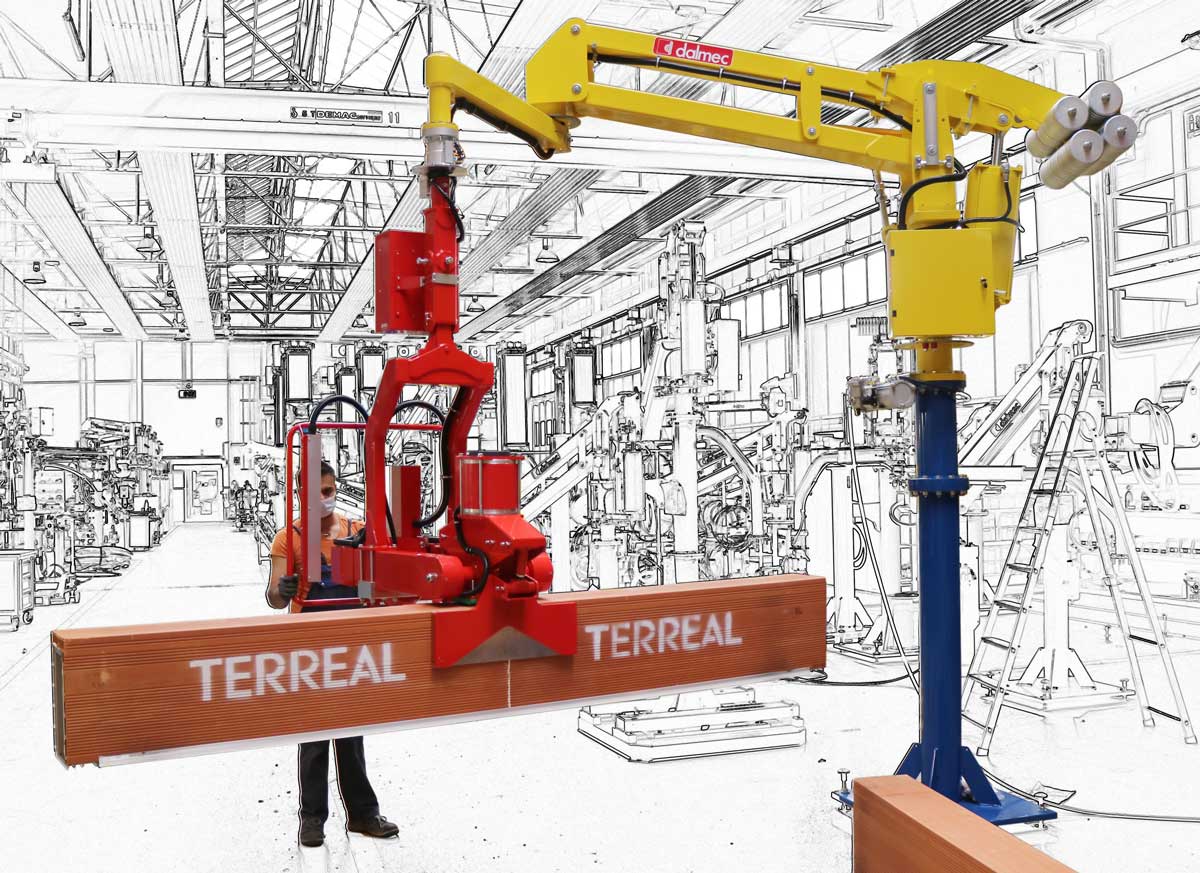

Pneumatic Manipulator MAXIPARTNER EQUO ME with articulated arms, equipped with special gripping tools, is suitable to handle heavy (max 900 kg) and also off-set loads, in any direction, allowing the operator to work with the minimum effort in good ergonomic and safety conditions.

Its slim and strong structure eliminates the “drifting” effect.

OPERATION

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied.

The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced.

The operator can change the load level simply operating a pneumatic control lever.