MLGC Series Compact External Guide Cylinder With Fine Lock – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

Fine lock cylinder with built-in lock mechanism and guide rod are integrated compactly.

[Features]

・ New guide body reduces mass by 9%

・ It can be locked in both directions

・ Maximum piston speed: 500 mm/s

・ Air cushion is equipped as standard

・ Operating position can be detected

Danh mục: AUTOMATION, Cylinders With Guides - Xi Lanh Khí Nén SMC, SMC

Download

MLGC Series Compact External Guide Cylinder With Fine Lock Details – Xi Lanh Khí Nén SMC

MLGC Series Compact External Guide Cylinder With Fine Lock product image

MLGC Series Compact External Guide Cylinder With Fine Lock Specifications

| Model | MLGC□□20 | MLGC□□25 | MLGC□□32 | MLG□□40 | |

|---|---|---|---|---|---|

| Basic Cylinder | CDLG1BA [Bore size] [Thread type] – [Stroke] – [Lock operation] – [Auto switch] | ||||

| Tube Inner Diameter (mm) | 20 | 25 | 32 | 40 | |

| Action | Double acting | ||||

| Fluid | Air | ||||

| Proof Pressure | 1.5 MPa | ||||

| Maximum operating pressure | 1.0 MPa | ||||

| Minimum operating pressure | 0.2 MPa (horizontal, no load) | ||||

| Ambient and Working Fluid Temperature | -10 to 60 ℃ | ||||

| Piston speed*1 | 50 to 500 mm/s | ||||

| Cushioning | Air cushion | ||||

| Basic Cylinder Lubrication | Not required | ||||

| Stroke Length Tolerance | (+0.2 to +1.9) mm | ||||

| Non-rotating accuracy*2 | Slide bearing | ±0.06 ° | ±0.05 ° | ±0.05 ° | ±0.04 ° |

| Ball Bushing Bearing | ±0.04 ° | ±0.04 ° | ±0.04 ° | ±0.04 ° | |

| Piping port size*3 (Rc, NPT) |

Cylinder port | M5 × 0.8 | 1/8 | ||

| Lock port | 1/8 | ||||

| Locking Method | ■ Spring locking (exhaust locking) ■ Pneumatic locking (pressure locking) ■ Spring and pneumatic locking |

||||

- *1Constraints associated with the allowable kinetic energy are imposed on the speeds at which the piston can be locked. The maximum speed of 750 mm/s can be accommodated if the piston is to be locked in the stationary state for the purpose of drop prevention.

- *2When the cylinder is retracted (initial value), with no load or without deflection of the guide rod, the non-rotating accuracy shall be the value in the table or less.

- *3For bore size 20 and 25, M5 × 0.8 only is available.

Model/Stroke Table

| Model (Bearing Type) | Tube Inner Diameter (mm) | Standard Stroke (mm) | Long Stroke (mm) |

|---|---|---|---|

| MLGCM (slide bearing) MLGCL (ball bushing bearing) |

20 | 75, 100, 125, 150, 200 | 250, 300, 350, 400 |

| 25 | 75, 100, 125, 150 200, 250, 300 |

350, 400, 450, 500 | |

| 32 | 350, 400, 450, 500, 600 | ||

| 40 | 350, 400, 450, 500, 600, 700, 800 |

- *Intermediate and short strokes not listed above are produced to order.

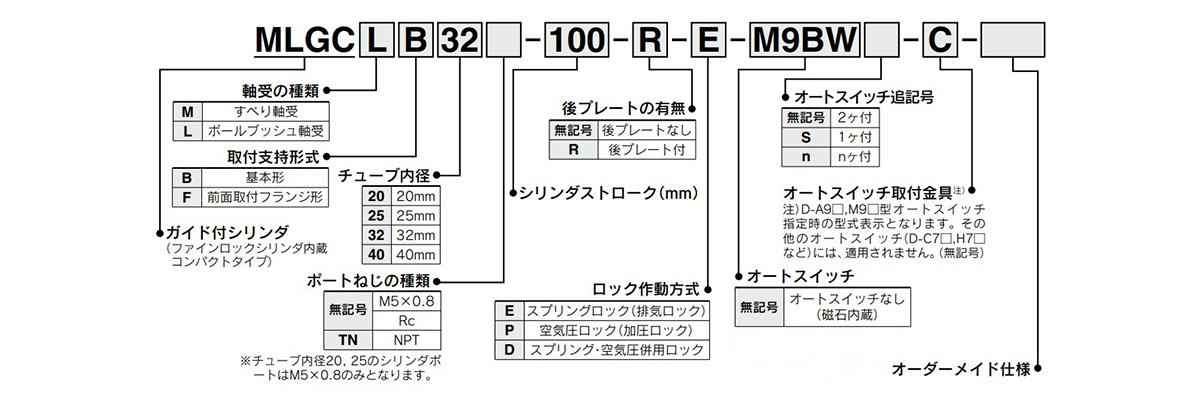

Model Number Notation

Model number examples

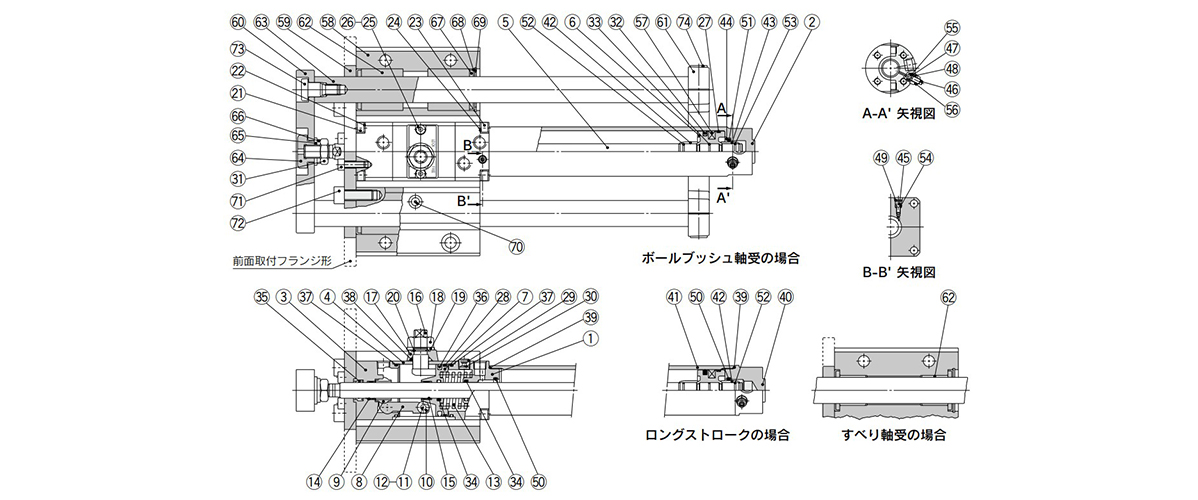

Diagram: With Rear Plate

Diagram: MLGC Series Compact External Guide Cylinder With Fine Lock

Components

| Number | Part Name | Material | Notes | |

|---|---|---|---|---|

| 1 | Rod cover | Aluminum alloy | Clear hard anodized | |

| 2 | Tube cover | Aluminum alloy | Hard anodized aluminum | |

| 3 | Cover | Carbon steel | Nitrided | |

| 4 | Intermediate Cover | Aluminum alloy | Clear hard anodized | |

| 5 | Piston rod | Carbon steel | Hard chrome plated | ø20 (20-mm diameter), ø25 (25-mm diameter): stainless steel |

| 6 | Piston | Aluminum alloy | Chromate | |

| 7 | Brake Piston | Carbon steel | Nitrided | |

| 8 | Brake Arm | Carbon steel | Nitrided | |

| 9 | Brake Shoe | Special friction material | – | |

| 10 | Roller | Carbon steel | Nitrided | |

| 11 | Pin | Carbon steel | Heat treated | |

| 12 | Retaining Ring | Stainless steel | – | |

| 13 | Brake spring | Spring steel wire | Dacrodized | For spring locking, spring/pneumatic locking |

| 14 | Bushing | Resin/Copper alloy (Multiple layers) | – | |

| 15 | Bushing | Resin/Copper alloy (Multiple layers) | – | |

| 16 | Manual Lock Release Cam | Chrome molybdenum steel | Nitrided, nickel plated | |

| 17 | Cam Guide | Carbon steel | Nitrided, painted | |

| 18 | Lock nut | Rolled steel | Nickel plated | |

| 19 | Flat Washer | Rolled steel | Nickel plated | |

| 20 | Retaining Ring | Stainless steel | – | |

| 21 | Hex Socket Head Cap Screw | Chrome molybdenum steel | Nickel plated | |

| 22 | Spring Washer | Steel wire | Nickel plated | |

| 23 | Hex Socket Head Cap Screw | Chrome molybdenum steel | Nickel plated | |

| 24 | Spring Washer | Steel wire | Nickel plated | |

| 25 | Hex Socket Head Cap Screw | Chrome molybdenum steel | Nickel plated | |

| 26 | Spring Washer | Steel wire | Nickel plated | |

| 27 | Wear Ring | Resin | – | |

| 28 | Wear Ring | Resin | – | |

| 29 | Hexagon socket head plug | Carbon steel | Nickel plated | E type only |

| 30 | Element | Bronze | – | |

| 31 | Rod end nut | Rolled steel | Nickel plated | |

| 32 | Piston packing | NBR | – | |

| 33 | Piston gasket | NBR | – | |

| 34 | Rod Seal A | NBR | – | |

| 35 | Rod Seal B | NBR | – | |

| 36 | Brake Piston Seal | NBR | – | |

| 37 | Intermediate Cover Gasket | NBR | – | |

| 38 | Cam Gasket | NBR | – | |

| 39 | Cylinder Tube Gasket | NBR | – | |

| 40 | Head cover | Aluminum alloy | Clear hard anodized | |

| 41 | Cylinder Tube | Aluminum alloy | Hard anodized aluminum | |

| 42 | Cushion Ring A | Aluminum alloy | Anodized aluminum | |

| 43 | Cushion Ring B | Aluminum alloy | Anodized aluminum | |

| 44 | Seal Retainer | Rolled steel | Zinc chromate | |

| 45 | Cushion valve A | Chrome molybdenum steel | Electroless nickel plating | |

| 46 | Cushion valve B | Rolled steel | Electroless nickel plating | |

| 47 | Valve retainer | Rolled steel | Electroless nickel plating | |

| 48 | Lock nut | Rolled steel | Nickel plated | |

| 49 | Retaining Ring | Stainless steel | – | |

| 50 | Cushion seal A | Urethane | – | |

| 51 | Cushion seal B | Urethane | – | |

| 52 | Cushion ring gasket A | NBR | – | |

| 53 | Cushion ring gasket B | NBR | – | |

| 54 | Valve seal A | NBR | – | |

| 55 | Valve seal B | NBR | – | |

| 56 | Valve retainer gasket | NBR | – | |

| 57 | Magnet | – | – | |

| 58 | Guide body | Aluminum alloy | Clear anodizing | |

| 59 | Small flange | Rolled steel | Nickel plated | Basic type |

| Large flange | Front mounting flange | |||

| 60 | Front plate | Rolled steel | Nickel plated | |

| 61 | Rear plate | Cast iron | Platinum silver | |

| 62 | Slide bearing | Resin/Copper alloy (Multiple layers) | For slide bearing | |

| Ball Bushing Bearing | – | For ball bushing bearing | ||

| 63 | Guide rod | Carbon steel | Hard chrome plated | For slide bearing |

| High carbon chrome bearing steel | Quenched, hard chrome plated | For ball bushing bearing | ||

| 64 | End bracket | Carbon steel | Nickel plated | |

| 65 | Flat Washer | Rolled steel | Nickel plated | |

| 66 | Spring Washer | Steel wire | Nickel plated | |

| 67 | Felt | Felt | – | |

| 68 | Holder | Stainless steel | – | |

| 69 | Type C Retaining Ring for Hole | Carbon tool steel | Phosphate conversion coating | |

| 70 | Grease nipple | – | Nickel plated | |

| 71 | Hex Socket Head Cap Screw | Chrome molybdenum steel | Nickel plated | For cylinder mounting |

| 72 | Hex Socket Head Cap Screw | Chrome molybdenum steel | Nickel plated | For large/small flange mounting |

| 73 | Bolt for guide | Chrome molybdenum steel | Nickel plated | For front plate mounting |

| 74 | Hex Socket Head Cap Screw | Chrome molybdenum steel | Nickel plated | For rear plate mounting |

- *For products without a rear plate, (61) and (74) are not required.

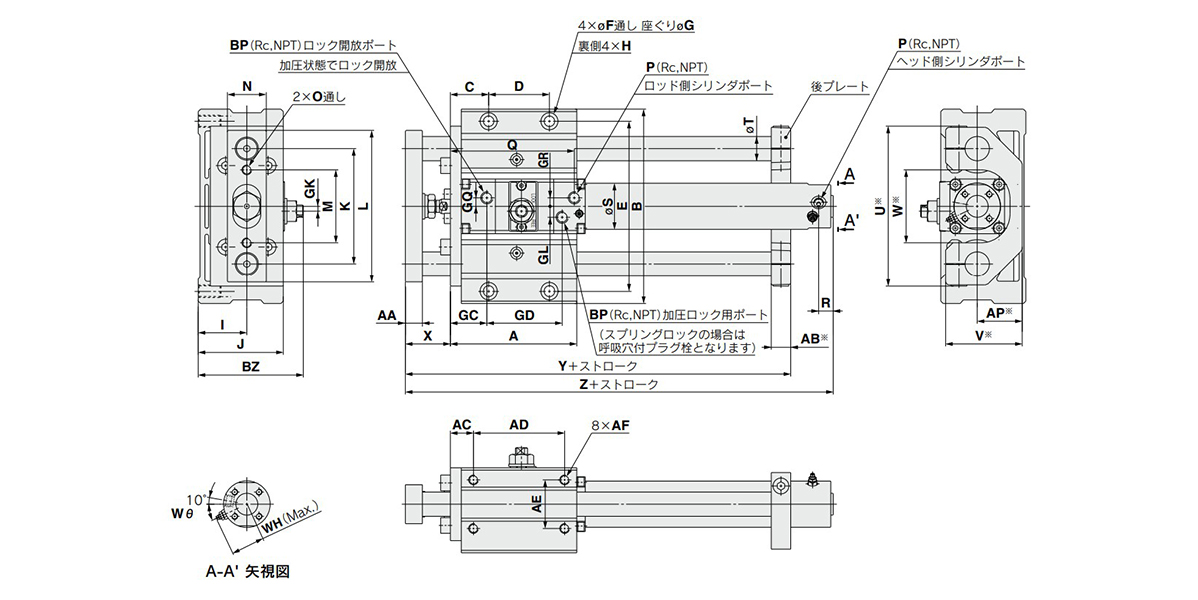

MLGC Series Compact External Guide Cylinder With Fine Lock Example Dimensions

(Units: mm)

Dimensional drawings: basic / with rear plate MLGC□B□□-□-R-□

With standard stroke

(Units: mm)

| Tube Inner Diameter (mm) | Stroke range (mm) | A | AA | AB* | AC | AD | AE | AF | AP* | B | BP*3 | BZ | C | D | E | F | G | GC |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 75, 100, 125, 150, 200 | 94 | 11 | 13 | 16.5 | 70 | 35 | M6 × 1 depth 12 | 32 | 135 | 1/8 | 73.5 | 26.5 | 50 | 118 | 6.8 | 11 depth 8 | 28 |

| 25 | 75, 100, 125, 150, 200, 250, 300 | 104 | 14 | 16 | 19 | 75 | 40 | M8 × 1.25 depth 16 | 37 | 160 | 1/8 | 86.5 | 31.5 | 50 | 140 | 8.6 | 14 depth 10 | 29 |

| 32 | 104 | 14 | 16 | 19 | 75 | 40 | M8 × 1.25 depth 16 | 37 | 160 | 1/8 | 86.5 | 31.5 | 50 | 140 | 8.6 | 14 depth 10 | 30 | |

| 40 | 142 | 17 | 19 | 22 | 110 | 45 | M10 × 1.5 depth 20 | 42 | 194 | 1/8 | 95 | 37 | 80 | 170 | 10.5 | 17 depth 12 | 35 |

(Units: mm)

| Tube Inner Diameter (mm) | GD | GK | GL | GQ | GR | H | I | J | K | L | M | N | O | P*2 | Q | R | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 54 | 3.5 | 5.5 | 4 | 4 | M8 × 1.25 depth 14 | 35 | 60 | 80 | 105 | 50 | 25 | M6 × 1 | M5 × 0.8 | 94 | 12 | 26 |

| 25 | 62 | 4 | 9 | 7 | 7 | M10 × 1.5 depth 18 | 40 | 70 | 95 | 125 | 60 | 32 | M8 × 1.25 | M5 × 0.8 | 104 | 12 | 31 |

| 32 | 62 | 4 | 9 | 7 | 7 | M10 × 1.5 depth 18 | 40 | 70 | 95 | 125 | 60 | 32 | M8 × 1.25 | 1/8 | 104 | 12 | 38 |

| 40 | 67 | 4 | 11 | 8 | 7 | M12 × 1.75 depth 21 | 45 | 82.5 | 115 | 150 | 75 | 38 | M8 × 1.25 | 1/8 | 115 | 12 | 47 |

(Units: mm)

| Tube Inner Diameter (mm) | T | U* | V* | W* | WH | W θ | X | Y | Z |

|---|---|---|---|---|---|---|---|---|---|

| 20 | 16 | 112 | 53 | 50 | 23 | 30 ° | 30 | 146 | 182 |

| 25 | 20 | 132 | 63 | 60 | 25 | 30 ° | 37 | 167 | 199 |

| 32 | 20 | 132 | 63 | 60 | 28.5 | 25 ° | 37 | 167 | 202 |

| 40 | 25 | 162 | 73 | 70 | 33 | 20 ° | 44 | 210 | 227 |

Without Rear Plate

(Units: mm)

| Tube Inner Diameter (mm) | Y |

|---|---|

| 20 | 129 |

| 25 | 146 |

| 32 | 146 |

| 40 | 191 |

Long Stroke

(Units: mm)

| Tube Inner Diameter (mm) | Stroke range (mm) | R | Z |

|---|---|---|---|

| 20 | 250 to 400 | 14 | 190 |

| 25 | 350 to 500 | 14 | 207 |

| 32 | 350 to 600 | 14 | 210 |

| 40 | 350 to 800 | 15 | 236 |

- *1: For products without a rear plate, dimensions marked with * are not required.

- *2: For bore size 20 and 25, M5 × 0.8 only is available. Rc, NPT and G ports are available for bore size 32 or greater.

- *3: Rc and NPT ports can be selected.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Guided |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | Cushion | Air cushion |

| Operating Pressure(MPa) | 0.2 to 1.0 | Specifications | Built-in magnet | Specification of cylinder | Built-in fine lock cylinder compact type |

| Locking Direction | Bidirectional |

MLGCLB20-15-R-D-H7BL

MLGCLB20-50-R-E

MLGCLB20-75-D

MLGCLB20-75-E

MLGCLB20-75-E-H7BWL

MLGCLB20-75-E-M9BAL-C

MLGCLB20-75-P

MLGCLB20-75-R-D

MLGCLB20-75-R-D-B73L

MLGCLB20-75-R-D-H7BWL

MLGCLB20-75-R-E

MLGCLB20-75-R-E-C73

MLGCLB20-75-R-E-C73Z

MLGCLB20-75-R-E-H7BW

MLGCLB20-75-R-E-M9BWSDPC3-C

MLGCLB20-50-R-E

MLGCLB20-75-D

MLGCLB20-75-E

MLGCLB20-75-E-H7BWL

MLGCLB20-75-E-M9BAL-C

MLGCLB20-75-P

MLGCLB20-75-R-D

MLGCLB20-75-R-D-B73L

MLGCLB20-75-R-D-H7BWL

MLGCLB20-75-R-E

MLGCLB20-75-R-E-C73

MLGCLB20-75-R-E-C73Z

MLGCLB20-75-R-E-H7BW

MLGCLB20-75-R-E-M9BWSDPC3-C

MLGCLB25-30-P

MLGCLB25-40-D-H7BWSDPC

MLGCLB25-50-D

MLGCLB25-50-D-C73L3

MLGCLB25-50-E

MLGCLB25-50-E-H7BW

MLGCLB25-75-D

MLGCLB25-75-D-C73L3

MLGCLB25-75-D-C735

MLGCLB25-75-D-H7BWL

MLGCLB25-75-E

MLGCLB25-75-E-H7BAL

MLGCLB25-75-E-H7BW

MLGCLB25-75-E-H7BWL3

MLGCLB25-40-D-H7BWSDPC

MLGCLB25-50-D

MLGCLB25-50-D-C73L3

MLGCLB25-50-E

MLGCLB25-50-E-H7BW

MLGCLB25-75-D

MLGCLB25-75-D-C73L3

MLGCLB25-75-D-C735

MLGCLB25-75-D-H7BWL

MLGCLB25-75-E

MLGCLB25-75-E-H7BAL

MLGCLB25-75-E-H7BW

MLGCLB25-75-E-H7BWL3

MLGCLB32-10-D

MLGCLB32-10-E

MLGCLB32-15-E

MLGCLB32-25-R-D

MLGCLB32-30-R-D-C73

MLGCLB32-30-R-D-C73C

MLGCLB32-30-R-D-C73CS

MLGCLB32-30-R-E

MLGCLB32-30-R-E-C73CS

MLGCLB40-20-R-E-H7BAL

MLGCLB40-50-E

MLGCLB40-50-E-A93

MLGCLB40-50-E-A93L4

MLGCLB40-50-E-H7BAL

MLGCLB40-50-R-E-M9BWLS

MLGCLB40-70-R-E

MLGCLB40-70-R-E-K59WLS

MLGCLB32-10-E

MLGCLB32-15-E

MLGCLB32-25-R-D

MLGCLB32-30-R-D-C73

MLGCLB32-30-R-D-C73C

MLGCLB32-30-R-D-C73CS

MLGCLB32-30-R-E

MLGCLB32-30-R-E-C73CS

MLGCLB40-20-R-E-H7BAL

MLGCLB40-50-E

MLGCLB40-50-E-A93

MLGCLB40-50-E-A93L4

MLGCLB40-50-E-H7BAL

MLGCLB40-50-R-E-M9BWLS

MLGCLB40-70-R-E

MLGCLB40-70-R-E-K59WLS