Mechanically Jointed Rodless Cylinder, Cam Follower Guide Type, MY1C Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

An air slide table made by SMC

[Features]

· Capable of smooth operation even when there is an unbalanced load

· Moment-resistant and capable of supporting long strokes

Download

Details of Mechanical Joint Type Rodless Cylinder, Cam Follower Guide Type MY1C Series – Xi Lanh Khí Nén SMC

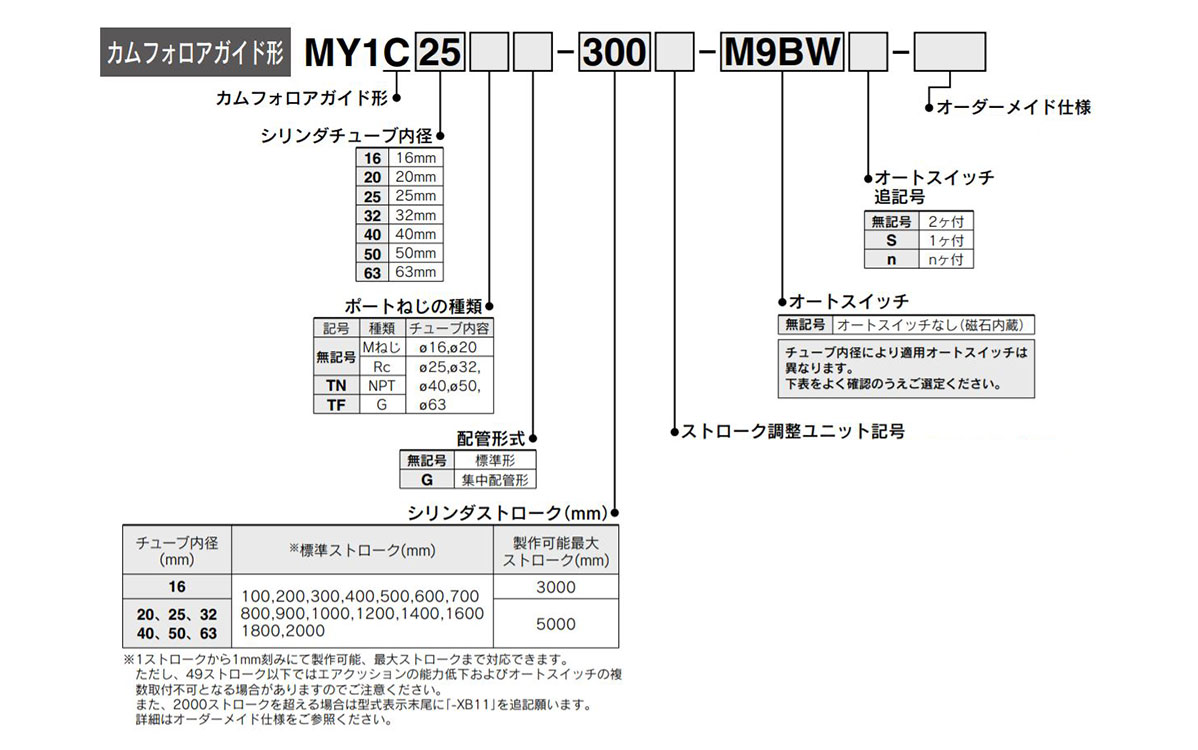

Model number examples

* Strokes can be manufactured in increments of 1 mm starting from 1 stroke up to the maximum stroke. However, note that if the stroke is 49 strokes or less, the air cushion capacity may decline and mounting multiple auto switches may not be possible.

* Please refer to the catalog for the stroke adjustment unit.

Standard Specifications

| Tube Internal Diameter (mm) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | |

|---|---|---|---|---|---|---|---|---|

| Fluid | Air | |||||||

| Operation Type | Double-acting type | |||||||

| Operating Pressure Range | 0.15 to 0.8 MPa | 0.1 to 0.8 MPa | ||||||

| Proof Pressure | 1.2 MPa | |||||||

| Ambient and fluid temperature | 5 to 60°C | |||||||

| Cushioning | Air cushion | |||||||

| Lubrication | Not required | |||||||

| Stroke Length Tolerance | 1,000 or less (0~+1.8) 1,001 to 3,000 (0~+2.8) |

2,700 or less (0 to +1.8), 2,701 to 5,000 (0~+2.8) | ||||||

| Piping Connection Port Diameter | Front/side port | M5 × 0.8 | Rc 1/8 | Rc 1/4 | Rc 3/8 | |||

| Bottom port | ø4 (Port size 4 mm) | ø6 (Port size 6 mm) | ø8 (Port size 8 mm) | ø10 (Port size 10 mm) | ||||

Piston Speed

| Tube Internal Diameter (mm) | 16 to 63 | |

|---|---|---|

| No stroke adjustment unit | 100 to 1,000 mm/s | |

| Stroke adjustment unit | A unit | *1) 100 to 1,000 mm/s |

| L unit, H unit | *2) 100 to 1,500 mm/s | |

*1) Be aware that if the stroke adjustment allowance with the adjust bolt leveling mount increases, the air cushion capacity will decrease. Meanwhile, in ranges exceeding the air cushion stroke, the working piston speed will become 100 to 200 mm/s.

*2) The piston speed used for centralized piping is 100 to 1,000 mm/s.

*3) Use at a speed within the range of the absorption capacity. See catalog.

Theoretical Output Table

(Unit: N)

| Tube Internal diameter (mm) |

Pressure received Area (mm^2) |

Operating Pressure (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | ||

| 16 | 200 | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| 20 | 314 | 62 | 94 | 125 | 157 | 188 | 219 | 251 |

| 25 | 490 | 98 | 147 | 196 | 245 | 294 | 343 | 392 |

| 32 | 804 | 161 | 241 | 322 | 402 | 483 | 563 | 643 |

| 40 | 1,256 | 251 | 377 | 502 | 628 | 754 | 879 | 1,005 |

| 50 | 1,962 | 392 | 588 | 784 | 981 | 1,177 | 1,373 | 1,569 |

| 63 | 3,115 | 623 | 934 | 1,246 | 1,557 | 1,869 | 2,180 | 2,492 |

*) Theoretical output (N) = pressure (MPa) × pressure receiving area (mm^2).

Weight Table

(Unit: kg)

| Tube Internal diameter (mm) |

Basic Weight |

Extra weight per 50 strokes |

Movable Part Weight |

Side support Bracket weight (Per pair) |

Stroke adjustment unit weight (Per unit) |

||

|---|---|---|---|---|---|---|---|

| A/B type | A unit Weight |

L unit Weight |

H unit Weight |

||||

| 16 | 0.67 | 0.12 | 0.22 | 0.01 | 0.03 | 0.04 | – |

| 20 | 1.06 | 0.15 | 0.31 | 0.02 | 0.04 | 0.05 | 0.08 |

| 25 | 1.58 | 0.24 | 0.41 | 0.02 | 0.07 | 0.11 | 0.18 |

| 32 | 3.14 | 0.37 | 0.86 | 0.04 | 0.14 | 0.23 | 0.39 |

| 40 | 5.60 | 0.52 | 1.49 | 0.08 | 0.25 | 0.34 | 0.48 |

| 50 | 10.14 | 0.76 | 2.59 | 0.08 | 0.36 | 0.51 | 3.38 |

| 63 | 16.67 | 1.10 | 4.26 | 0.17 | 0.68 | 0.83 | 1.08 |

Calculation method/example: MY1C25-300 A

- Basic weight: 1.58 kg

- Extra weight: 0.24/50st

- A unit weight: 0.07 kg

- Cylinder Stroke: 300st

1.58 + 0.24 × 300 ÷ 50 + 0.07 × 2≒3.16 kg

Specifications of options

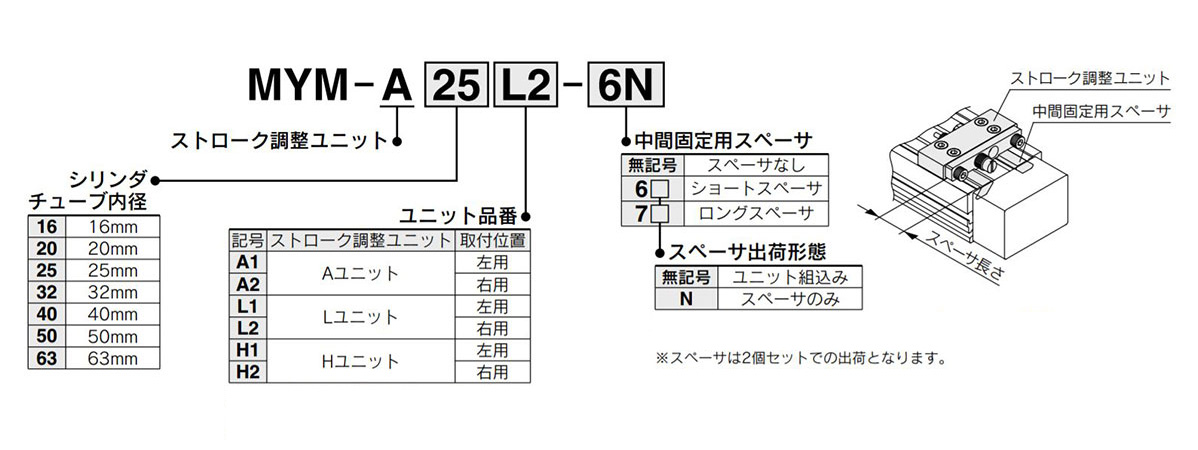

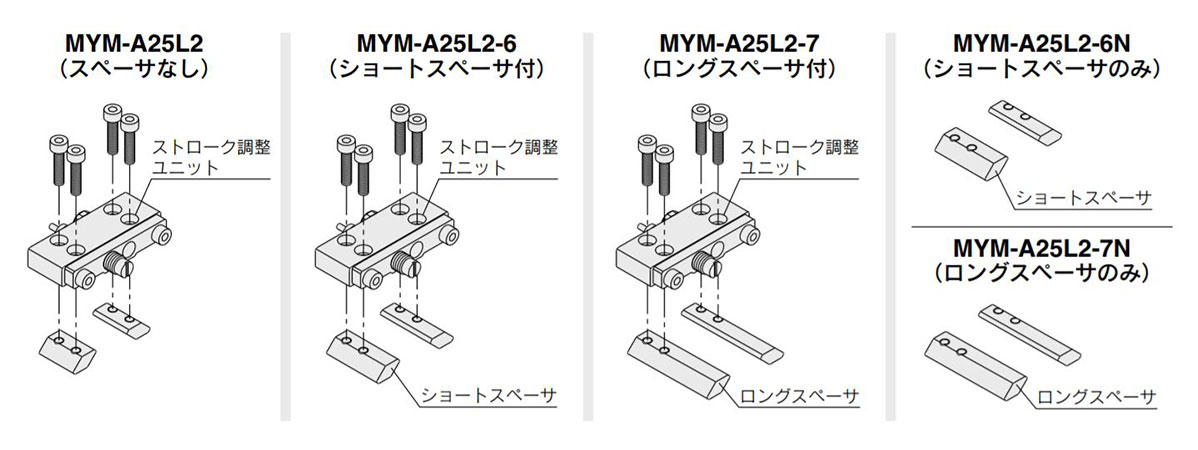

Model identification method for options, image

*1) Refer to the catalog for details on the adjustment range.

*2) ø16 (cylinder inner diameter: 16 mm) is available for A and L units only.

* The spacer is a mounting bracket for fixing the stroke adjustment unit at the intermediate position of the stroke.

Optional components

Optional component image

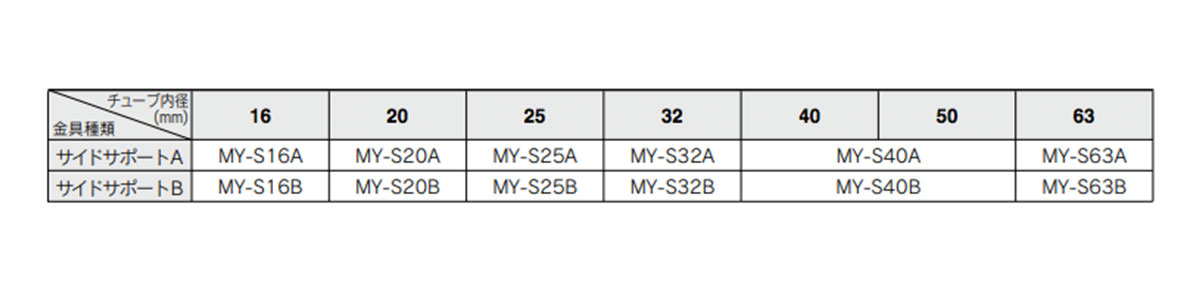

Side support model

Image of side support model table

- * Please refer to the catalog for details such as dimensions.

- * The side support is a pair on the left and right.

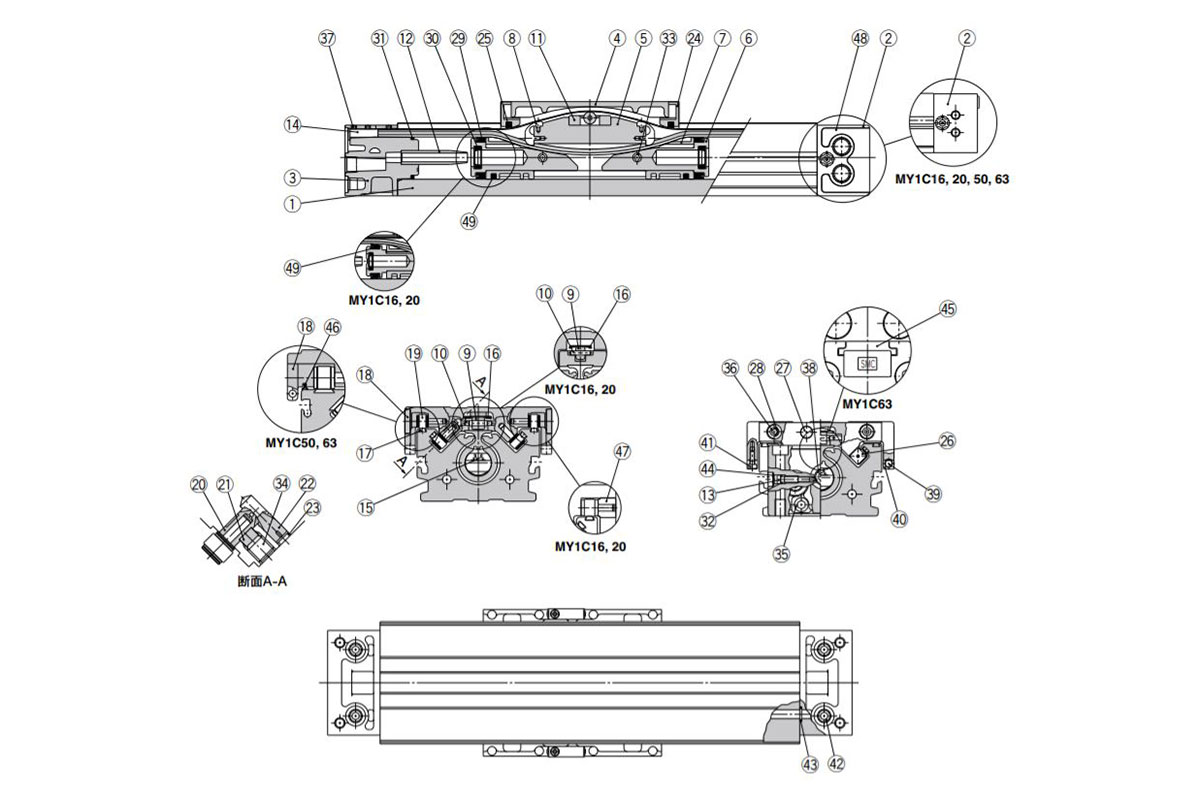

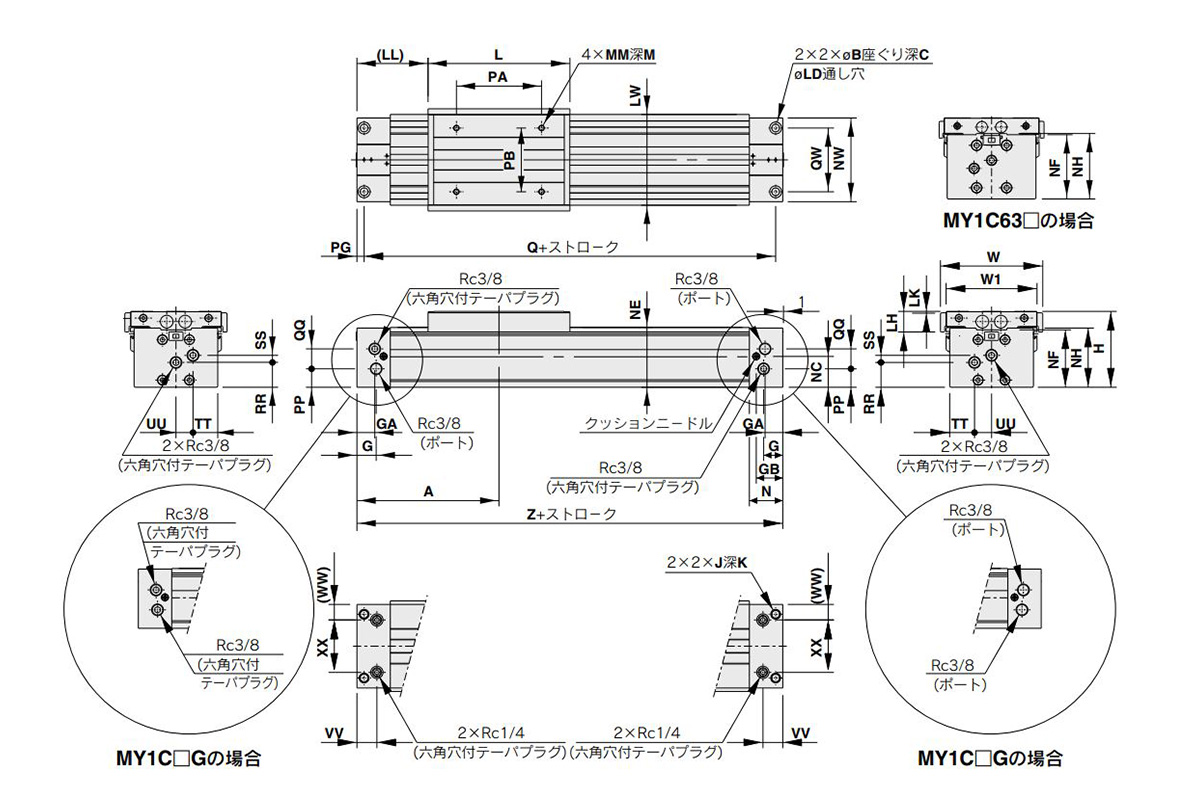

Diagram

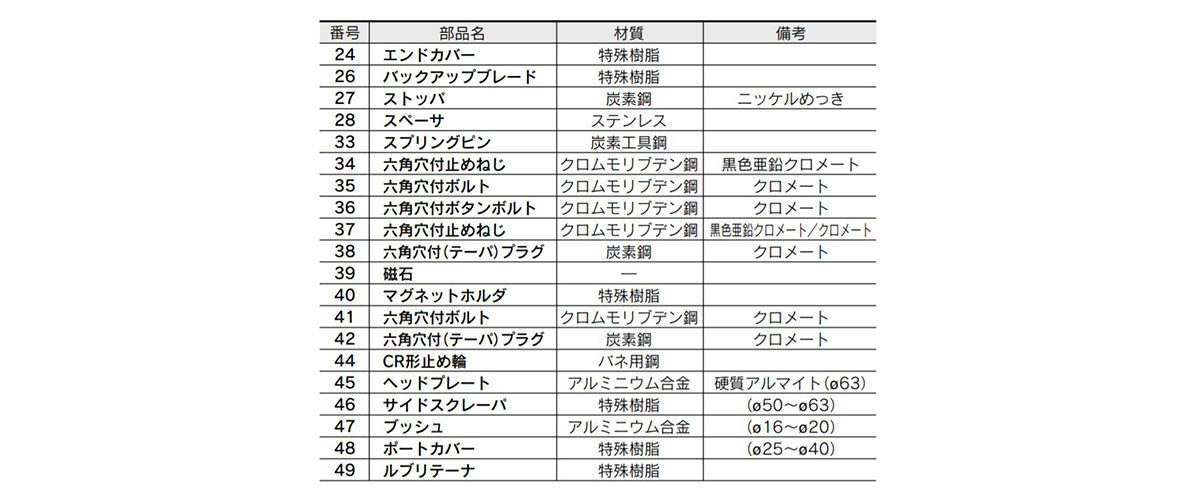

Structural drawing of Mechanical Joint Type Rodless Cylinder, Cam Follower Guide Type MY1C Series

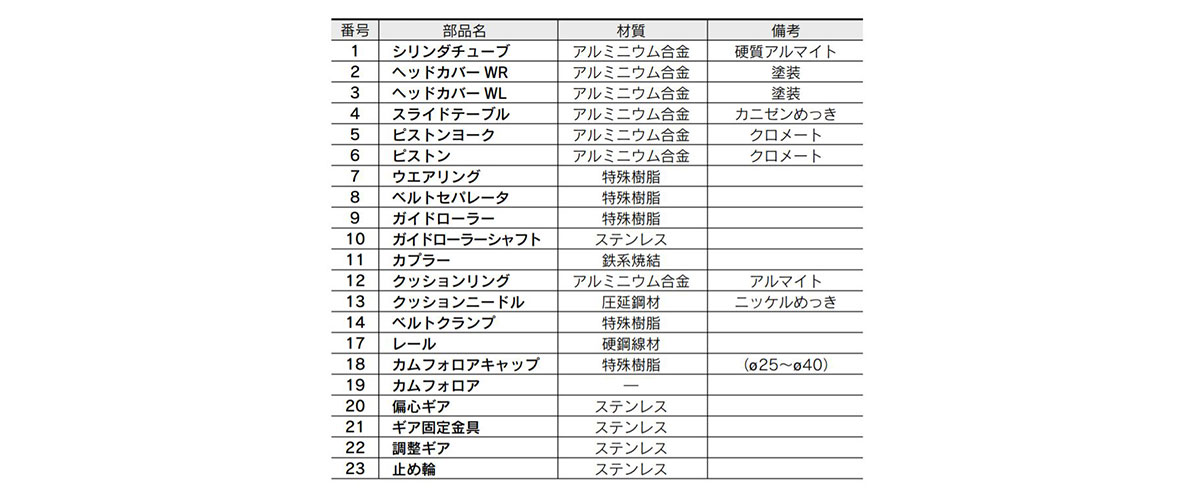

Component parts table image

Image 1 for components parts table

Image 2 for components parts table

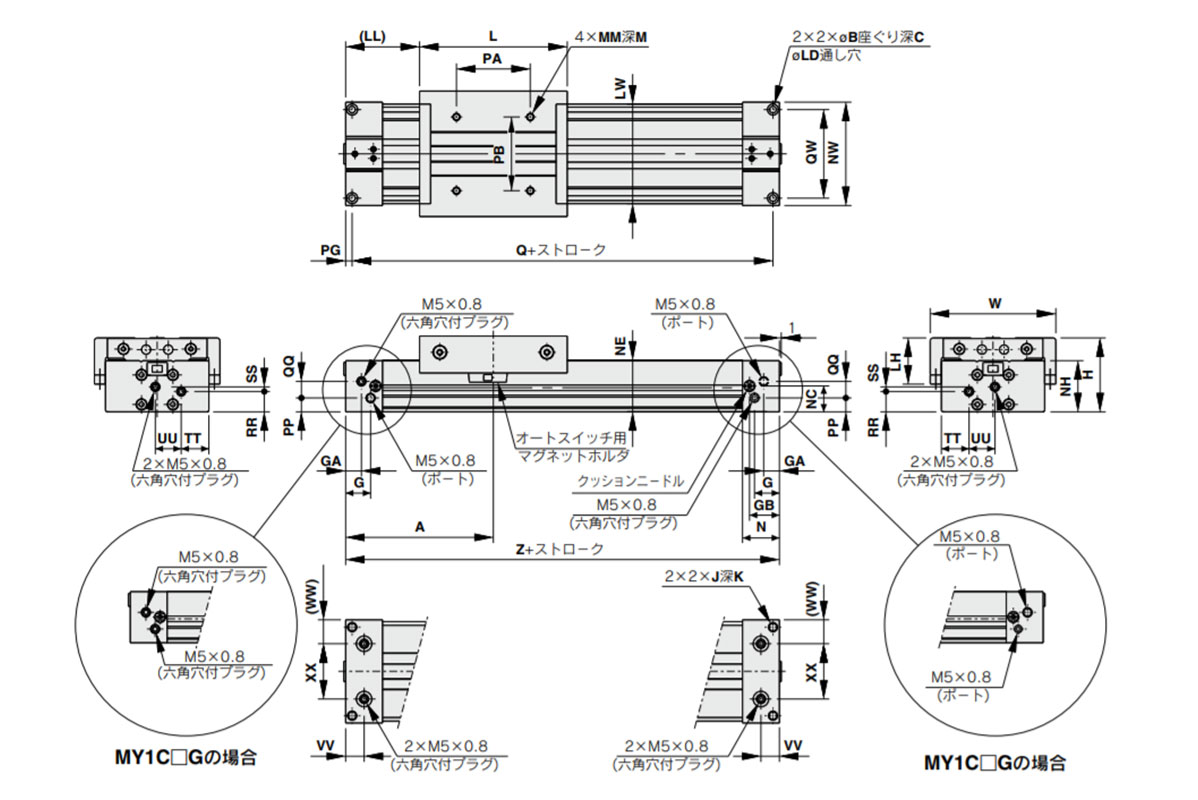

Dimensions example of mechanical Joint Type Rodless Cylinder, Cam Follower Guide Type MY1C Series

Standard type / centralized piping type ø16 (Cylinder inner diameter: 16 mm) ø20 (Cylinder inner diameter: 20 mm)

(Units: mm)

Dimensional drawing of MY1C16□/MY1C20□-Stroke

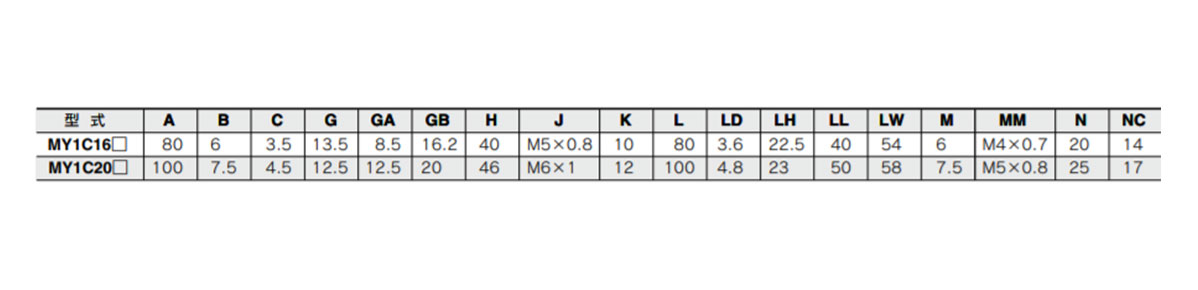

(Units: mm)

Dimension table image 1 of MY1C16□/MY1C20□

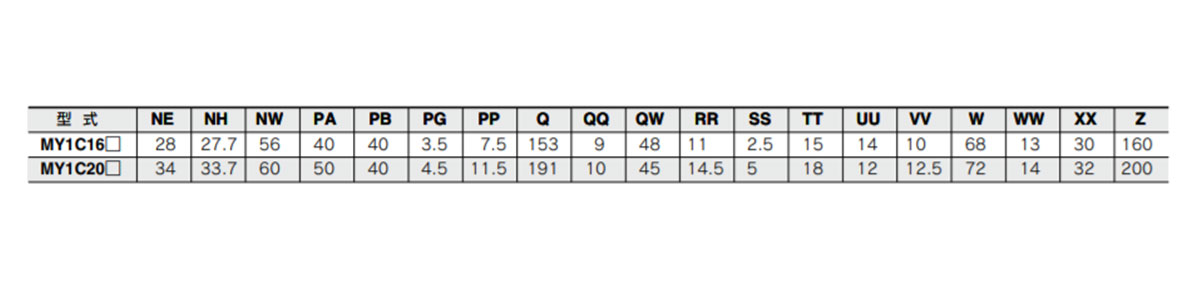

(Units: mm)

Dimension table image 2 of MY1C16□/MY1C20□

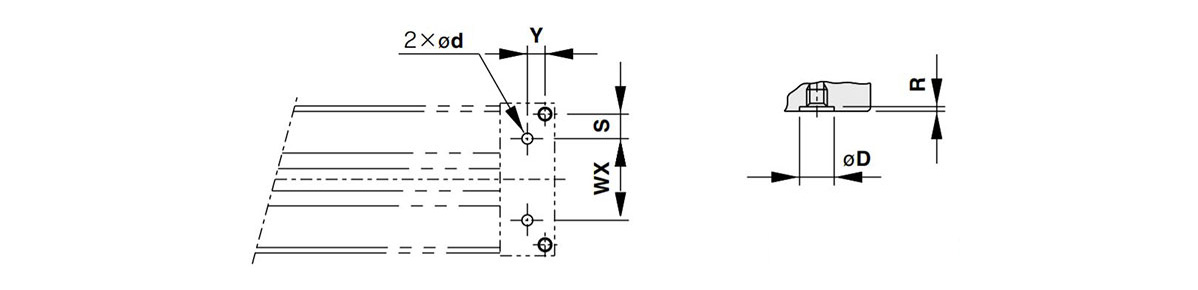

Piping hole dimensional drawing for centralized bottom piping of MY1C16□/MY1C20□ (right: Bottom side piping (Applicable O-ring)

(Units: mm)

Image of piping hole dimension table for centralized bottom piping

* Please process the mounting surface with these dimensions.

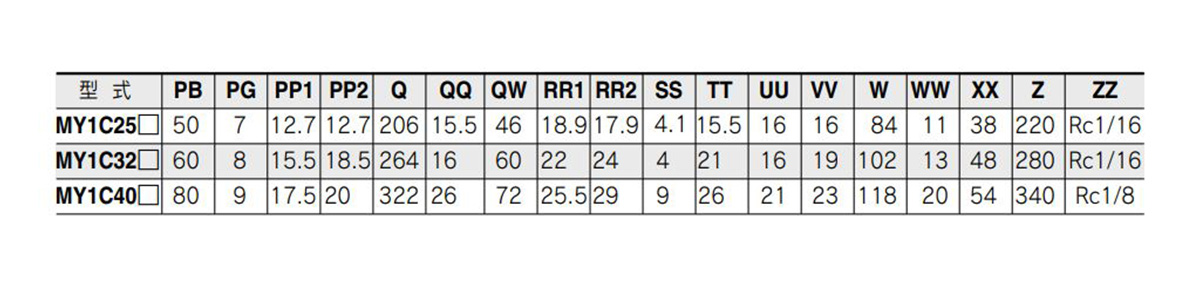

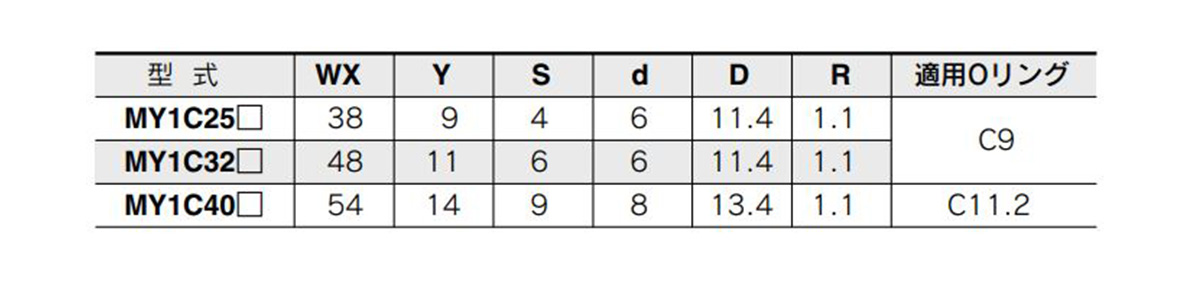

Standard type / centralized piping type ø25 (Cylinder inner diameter: 25 mm) ø32 (Cylinder inner diameter: 32 mm), ø40 (Cylinder inner diameter: 40 mm)

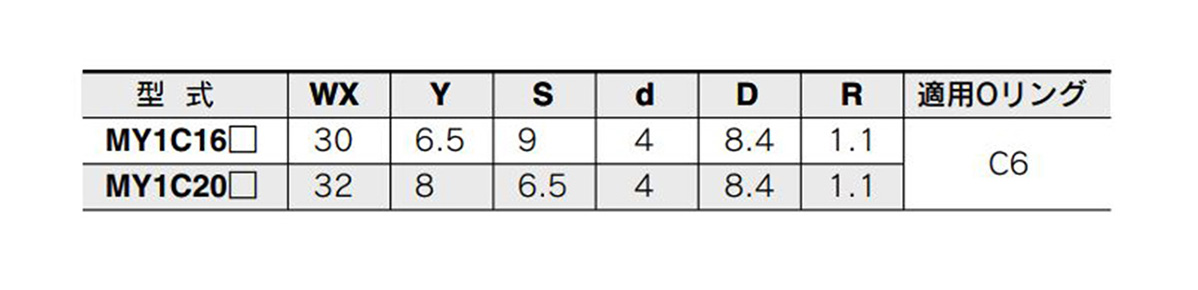

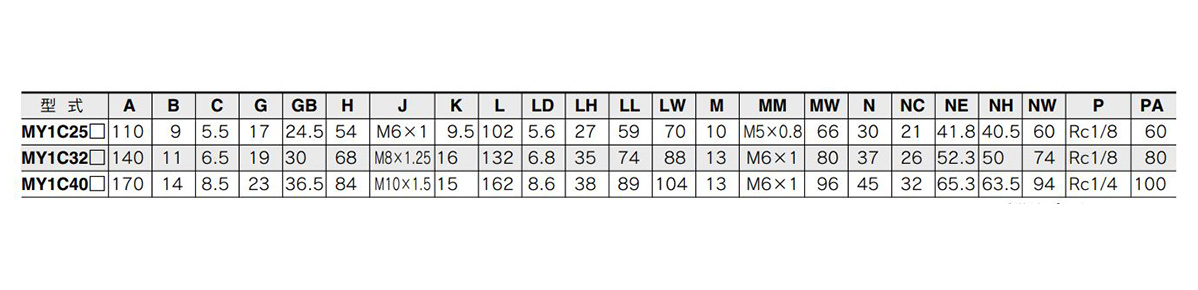

Dimensional drawing of MY1C25□/MY1C2532□/MY1C2540□-Stroke

(Units: mm)

Dimension table image 1 of MY1C25□/MY1C2532□/MY1C2540□

* P indicates the cylinder supply port.

(Units: mm)

Dimension table image 2 of MY1C25□/MY1C2532□/MY1C2540□

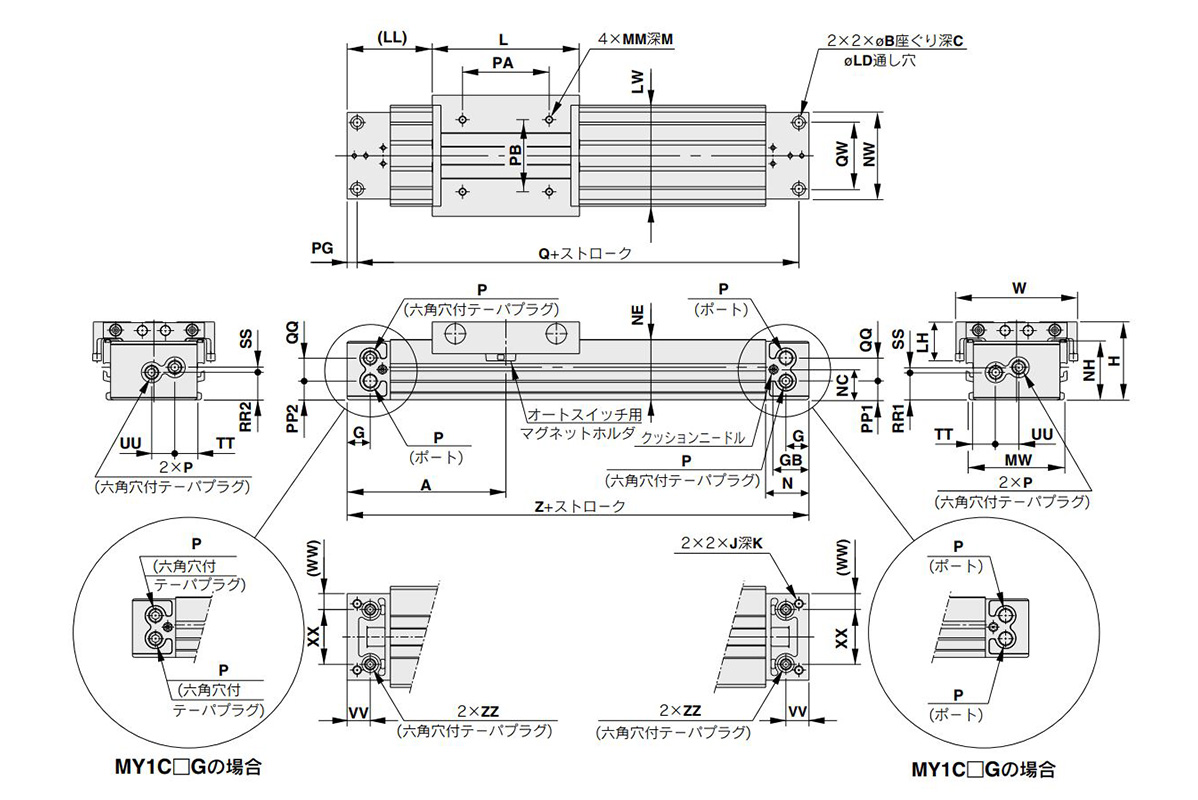

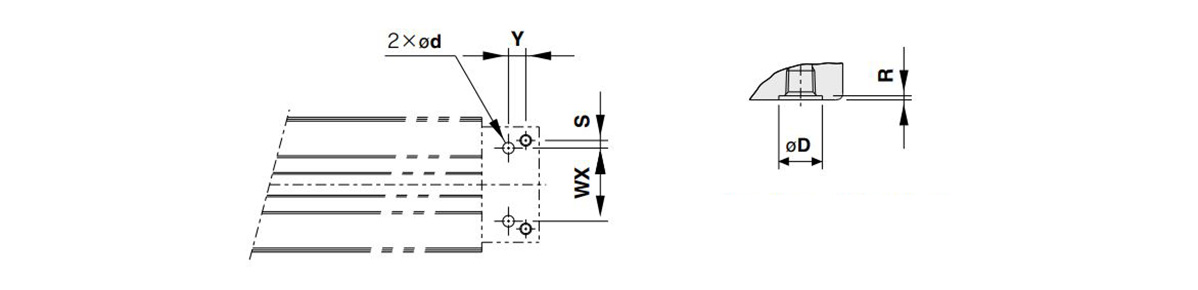

Piping hole dimensional drawing for centralized bottom piping of MY1C25□/MY1C2532□/MY1C2540 (right: Bottom side (ZZ section) piping section (applicable O-ring)

(Units: mm)

Image of piping hole dimension table for centralized bottom piping MY1C25□/MY1C2532□/MY1C2540□

* Please process the mounting surface with these dimensions.

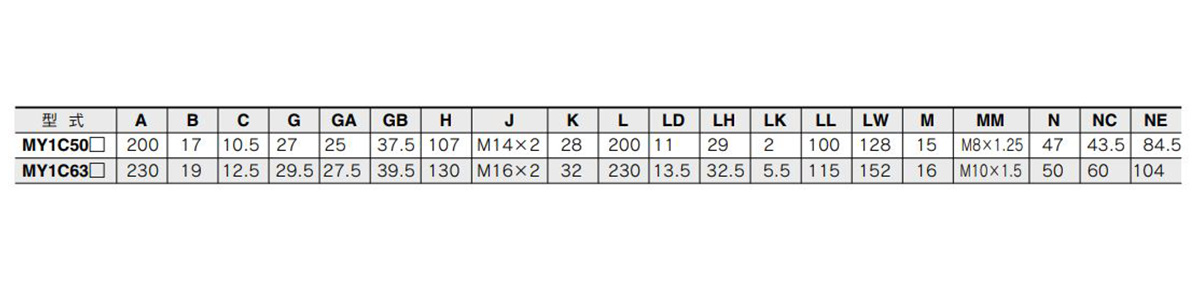

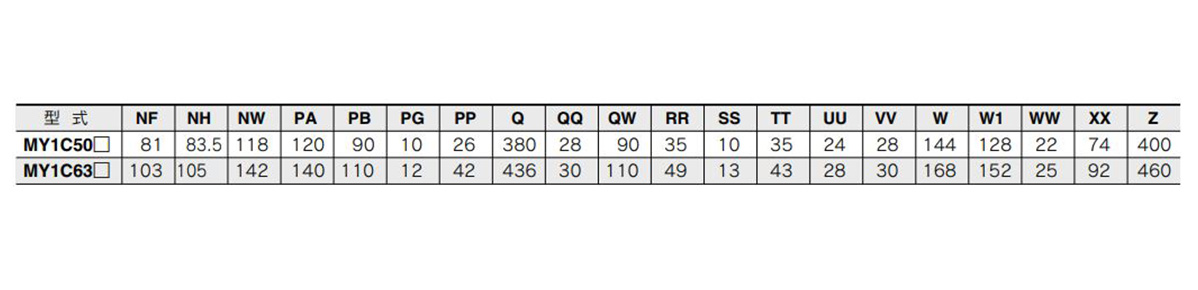

Standard type/ Centralized piping type ø50 (Cylinder inner diameter: 50 mm) ø63 (Cylinder inner diameter: 63 mm)

Dimensional drawing of MY1C50□/MY1C5063□ Stroke

(Units: mm)

Dimension table image 1 of MY1C50□/MY1C5063□

(Units: mm)

Dimension table image 2 of MY1C50□/MY1C5063□

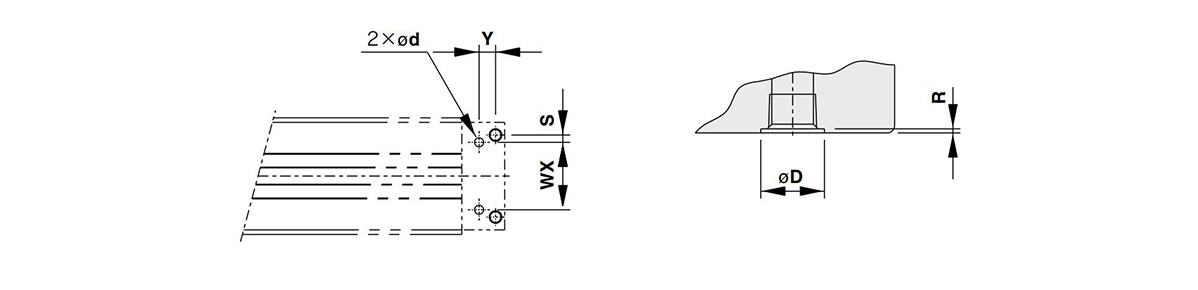

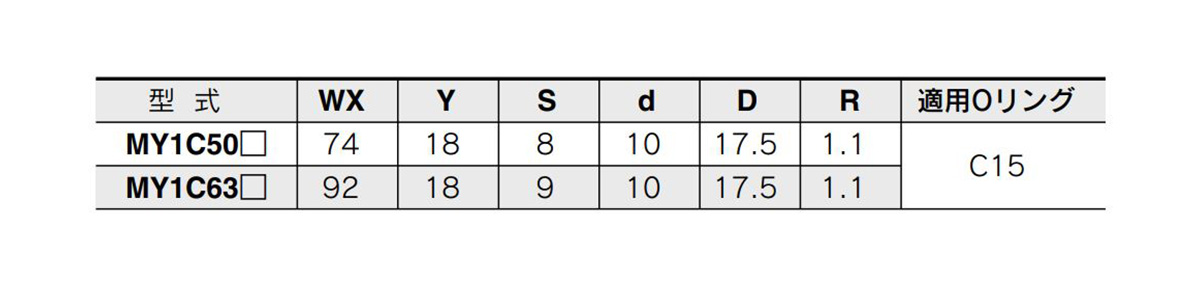

Piping hole dimensional drawing for centralized bottom piping of MY1C50□/MY1C5063□ (right: Bottom side (ZZ section) piping section (applicable O-ring)

(Units: mm)

Image of piping hole dimension table for centralized bottom piping MY1C50□/MY1C5063□

* Please process the mounting surface with these dimensions.

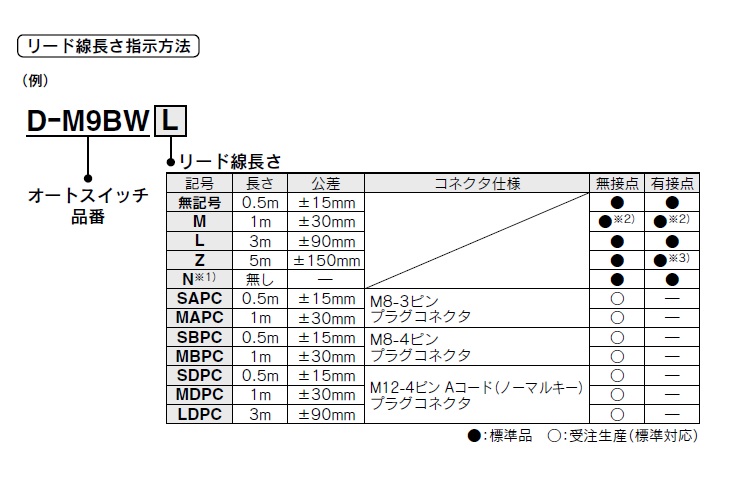

Please refer to the table below for details about lead wire / connector specifications.

Basic Information

| Type | Rodless Cylinder | Rodless Cylinder Joint Type | Mechanically Jointed |

|---|

MY1C16-50A-M9BWVSDPC

MY1C16-50A-M9BWVSDPCS

MY1C16-52

MY1C16-75L

MY1C16-80

MY1C16-80L-A93L

MY1C16-85

MY1C16-85-M9BW

MY1C16-90

MY1C16-90A-M9NVL

MY1C16-95

MY1C16-100

MY1C16-1000

MY1C16-1000-A90

MY1C16-1000-A90L

MY1C20-55L

MY1C20-60

MY1C20-60L

MY1C20-70

MY1C20-75

MY1C20-100

MY1C20-1000

MY1C20-1000-A90

MY1C20-1000-A90L

MY1C20-1000-A90LS

MY1C20-1000-A90S

MY1C20-1000-A90V

MY1C20-1000-A90VL

MY1C20-1000-A90VLS

MY1C20-1000-A90VS

MY1C20-1000-A93

MY1C20-1000-A93L

MY1C25-75

MY1C25-75-M9BL

MY1C25-75L-M9NL

MY1C25-80

MY1C25-80A-Z73L

MY1C25-80H

MY1C25-80H-Z73L

MY1C25-95L-Z73

MY1C25-100

MY1C25-1000

MY1C25-1000-M9BWL

MY1C25-1000-M9BWVSDPC

MY1C25-1000-M9N

MY1C25-1000-XC67

MY1C32-50-M9BVL5

MY1C32-50A

MY1C32-50A-XC56

MY1C32-50L-M9N

MY1C32-50L-M9NL

MY1C32-53

MY1C32-60

MY1C32-60L

MY1C32-60L-M9N

MY1C32-65

MY1C32-65H

MY1C32-75

MY1C32-80

MY1C32-80A

MY1C32-80L-M9N

MY1C32-80L-Y59A

MY1C40-53

MY1C40-55

MY1C40-55L-Z73L

MY1C40-60

MY1C40-60H

MY1C40-60L-M9NL

MY1C40-65

MY1C40-66

MY1C40-80

MY1C50-50-XC56

MY1C50-70

MY1C50-70H

MY1C50-73

MY1C50-73-Z73L

MY1C50-100

MY1C50-1000

MY1C50-1000-M9B

MY1C50-1000-M9BW

MY1C50-1000-M9BWL

MY1C50-1000-Y7BW

MY1C63-100

MY1C63-1000

MY1C63-1000-M9BW

MY1C63-1000-M9NL

MY1C63-1000-Y7BW

MY1C63-1000-Y7BWL

MY1C63-1000-Y7BWLS

MY1C63-1000-Y7BWS

MY1C63-1000-Y7BWV

MY1C63-1000-Y7BWVL

MY1C63-1000-Y7BWVL3