Mechanically Jointed Rodless Cylinder, Basic Type, MY1B-Z Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

The MY1B-Z series is a basic type of Mechanically Jointed Rodless Cylinder in which piping is possible from 4 directions.

[Features]

· Adjusting the cushion needle is easy.

· An auto switch is mountable to either the front or rear sides.

Download

Mechanical Joint Type Rodless Cylinder, Basic Type, MY1B-Z Series Specifications – Xi Lanh Khí Nén SMC

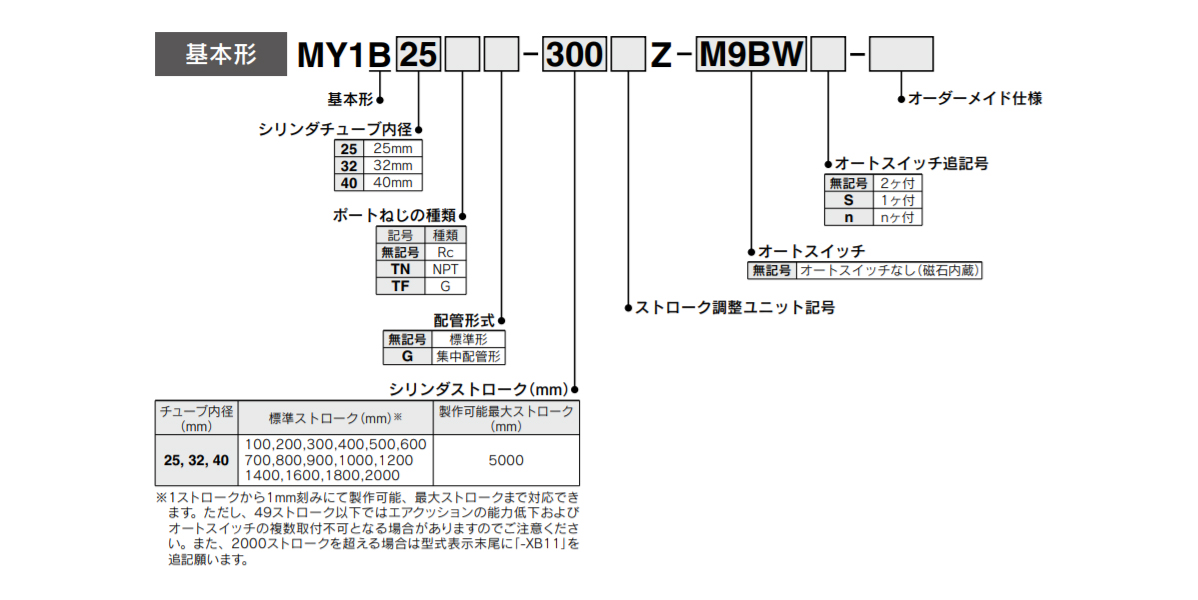

Model Indication Method

Model Indication Method

Specifications

| Tube inner diameter (mm) | 25 | 32 | 40 | |

|---|---|---|---|---|

| Usable fluids | Air | |||

| Operating type | Double-acting type | |||

| Operating pressure range | 0.1 to 0.8 MPa | |||

| Guaranteed pressure resistance | 1.2 MPa | |||

| Ambient temperature and working fluid temperature | 5 to 60°C | |||

| Cushion | Air cushion | |||

| Lubrication | Lubrication-free | |||

| Allowable difference of stroke length | 2,700 or less (0 to +1.8), 2,701 to 5,000 (0 to +2.8) | |||

| Piping connection port diameter | Front/side port | Rc 1/8 | Rc 1/4 | |

| Bottom port | ø6 (diameter 6 mm) | ø8 (diameter 8 mm) | ||

Theoretical output table

Unit: N

| Tube inner diameter (mm) |

Pressure receiving area (mm2) |

Operating pressure (MPa) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | ||

| 25 | 490 | 98 | 147 | 196 | 245 | 294 | 343 | 392 |

| 32 | 804 | 161 | 241 | 322 | 402 | 483 | 563 | 643 |

| 40 | 1,256 | 251 | 377 | 502 | 628 | 754 | 879 | 1,005 |

Note: Theoretical output (N) = pressure (MPa) × pressure receiving area (mm2).

Weight table

Unit: kg

| Tube inner diameter (mm) |

Basic weight | Extra weight per 50 strokes |

Side port bracket weight (per 1 pair) |

Stroke adjustment unit weight (per 1 unit) |

||

|---|---|---|---|---|---|---|

| A /B type | A unit weight |

L unit weight |

H unit weight |

|||

| 25 | 1.14 | 0.11 | 0.02 | 0.06 | 0.10 | 0.18 |

| 32 | 2.28 | 0.17 | 0.02 | 0.12 | 0.21 | 0.40 |

| 40 | 3.11 | 0.25 | 0.04 | 0.23 | 0.32 | 0.49 |

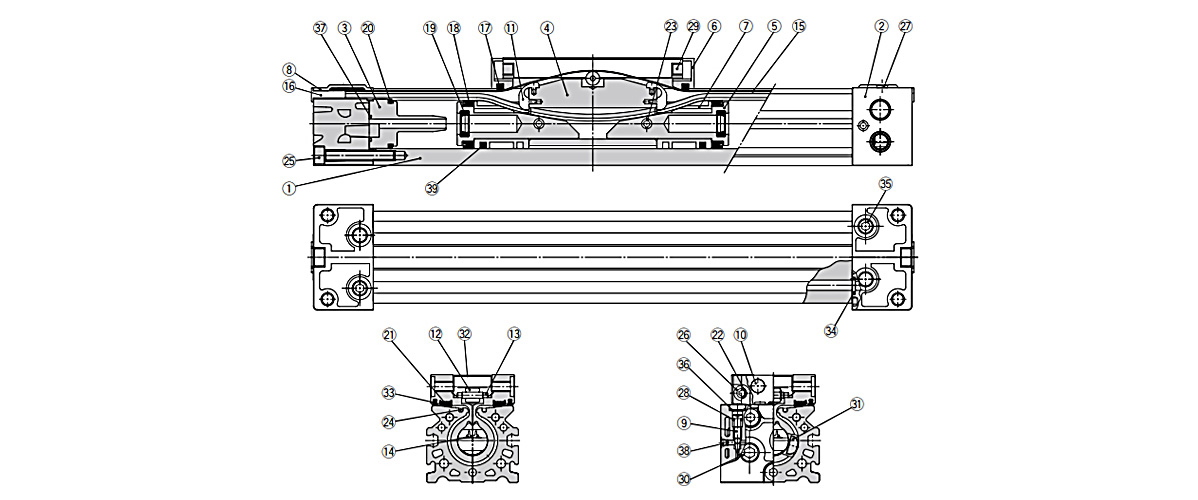

Structural Drawing

MY1B25 to 40

Components

| Number | Description | Materials | Additional notes |

|---|---|---|---|

| 1 | Cylinder tube | Aluminum alloy | Hard anodized aluminum |

| 2 | Head cover | Aluminum alloy | Painted |

| 3 | Cushion boss | Polyacetal | – |

| 4 | Piston yoke | Aluminum alloy | Anodized aluminum |

| 5 | Piston | Aluminum alloy | Chromate |

| 6 | End cover | Polyacetal | – |

| 7 | Wear ring | Polyacetal | – |

| 8 | Head plate | Stainless steel | – |

| 9 | Cushion needle | Rolled steel | Nickel plating |

| 10 | Stopper | Carbon steel | Nickel plating |

| 11 | Belt separator | Polyacetal | – |

| 12 | Guide roller | Polyacetal | – |

| 13 | Parallel pin | Carbon steel | – |

| 16 | Belt clamp | Polybutylene terephthalate | – |

| 21 | Bearing | Polyacetal | – |

| 22 | Spacer | Stainless steel | – |

| 23 | Spring pin | Carbon tool steel | – |

| 24 | Seal magnet | Rubber magnet | – |

| 25 | Hex socket head bolt | Chrome molybdenum steel | Chromate |

| 26 | Hex socket head cap button screw | Chrome molybdenum steel | Chromate |

| 27 | Thin-head screw | Chrome molybdenum steel | Chromate |

| 29 | Double-round parallel key | Carbon steel | – |

| 30 | Hex socket head taper plug | Carbon steel | Chromate (in the case of centralized piping: 7 pcs.) |

| 31 | Magnet | Rare earth magnet | – |

| 32 | Top cover | Stainless steel | – |

| 35 | Hex socket head taper plug | Carbon steel | Chromate (in the case of centralized piping: 3 pcs.) |

| 36 | CR-type retaining ring | Steel for springs | – |

| 38 | Steel ball | Bearing steel | – |

| 39 | Lub-retainer | Special resin | – |

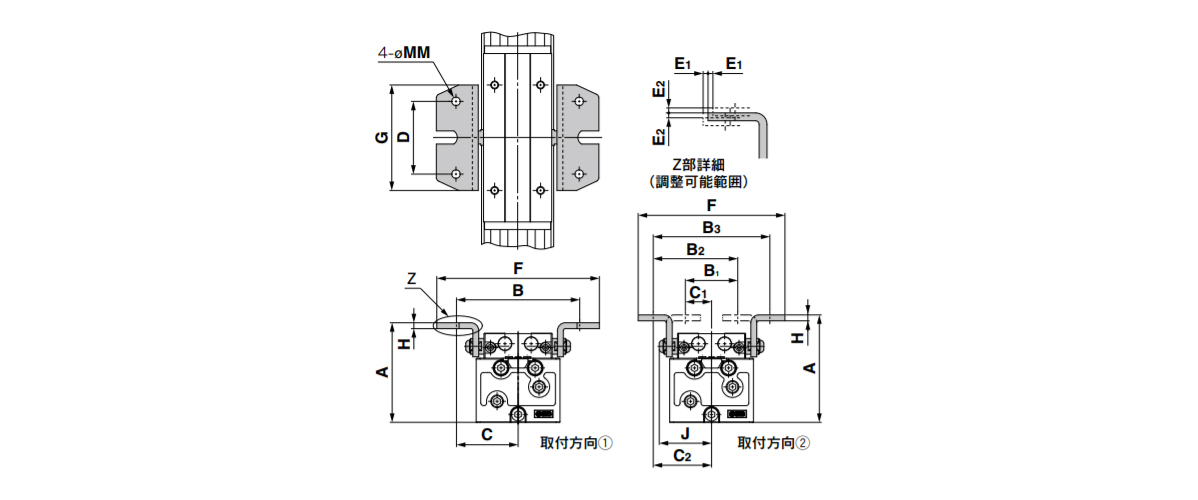

Mechanically Jointed Rodless Cylinder, Basic Type, MY1B-Z Series, example dimensions

L-type mounting dimensions

Mounting direction can be selected from 2 types with 1 pair of brackets, enabling compact combinations.

(Unit: mm)

| Model | Compatible cylinders | Common | Mounting direction (1) | Mounting direction (2) | Adjustable range | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D | G | H | J | MM | A | B | C | F | A | B1 | B2 | B3 | C1 | C2 | F | E1 | E2 | ||

| MY-J25 | MY1B25□ | 40 | 60 | 3.2 | 35 | 5.5 | 63 | 78 | 39 | 100 | 65 | 28 | 53 | 78 | 14 | 39 | 96 | 1 | 1 |

| MY-J32 | MY1B32□ | 55 | 80 | 4.5 | 40 | 6.5 | 76 | 94 | 47 | 124 | 82 | 40 | 64 | 88 | 20 | 44 | 111 | 1 | 1 |

| MY-J40 | MY1B40□ | 74 | 100 | 4.5 | 47 | 6.5 | 92 | 112 | 56 | 144 | 98 | 44 | 76 | 108 | 22 | 54 | 131 | 1 | 1 |

MY1B25-50LZ-M9BL

MY1B25-50Z-A93

MY1B25-60ALZ

MY1B25-60Z

MY1B25-60Z-M9B

MY1B25-70L7Z

MY1B25-70Z

MY1B25-70Z-M9N

MY1B25-75Z

MY1B25-75Z-M9BAL

MY1B25-80Z

MY1B25-80Z-M9N

MY1B25-90Z-M9N

MY1B25-95Z

MY1B25-95Z-M9BVL

MY1B25-1000A6Z

MY1B25-1000A6Z-A93L

MY1B25-1000A7Z

MY1B25-1000A7Z-M9BW

MY1B25-1000ALZ

MY1B25-1000AZ-A90

MY1B25-1000AZ-A93

MY1B25-1000AZ-A93L

MY1B25-1000AZ-M9BASBPC

MY1B25-1000AZ-M9BL

MY1B25-1000AZ-M9BM

MY1B25-1000AZ-M9N

MY1B25-1000AZ-M9NA

MY1B25-1000H6H7Z

MY1B25-1000H6H7Z-M9BL

MY1B25-50Z-A93

MY1B25-60ALZ

MY1B25-60Z

MY1B25-60Z-M9B

MY1B25-70L7Z

MY1B25-70Z

MY1B25-70Z-M9N

MY1B25-75Z

MY1B25-75Z-M9BAL

MY1B25-80Z

MY1B25-80Z-M9N

MY1B25-90Z-M9N

MY1B25-95Z

MY1B25-95Z-M9BVL

MY1B25-1000A6Z

MY1B25-1000A6Z-A93L

MY1B25-1000A7Z

MY1B25-1000A7Z-M9BW

MY1B25-1000ALZ

MY1B25-1000AZ-A90

MY1B25-1000AZ-A93

MY1B25-1000AZ-A93L

MY1B25-1000AZ-M9BASBPC

MY1B25-1000AZ-M9BL

MY1B25-1000AZ-M9BM

MY1B25-1000AZ-M9N

MY1B25-1000AZ-M9NA

MY1B25-1000H6H7Z

MY1B25-1000H6H7Z-M9BL

Part Number

MY1B32-50HZ

MY1B32-50LZ

MY1B32-50Z

MY1B32-55Z

MY1B32-55Z-A93

MY1B32-60HZ-M9BL

MY1B32-65AZ

MY1B32-65AZ-M9NL

MY1B32-65Z

MY1B32-1000A7Z-M9BW

MY1B32-1000AHZ-M9BWL

MY1B32-1000ALZ

MY1B32-1000ALZ-M9BL

MY1B32-1000AZ-A93

MY1B32-1000AZ-A93L

MY1B32-1000AZ-M9B

MY1B32-1000AZ-M9BAL

MY1B32-1000H6H7Z-M9B

MY1B32-1000H6H7Z-M9BV

MY1B32-1000H6Z

MY1B32-1000H6Z-M9BL

MY1B32-1000H7H6Z

MY1B32-1000H7SZ

MY1B32-1000H7Z

MY1B32-1000H7Z-M9BL

MY1B32-1000H7Z-M9NVL

MY1B32-1000HH6Z

MY1B32-1000HH6Z-A93L

MY1B32-1000HLZ

MY1B32-50HZ

MY1B32-50LZ

MY1B32-50Z

MY1B32-55Z

MY1B32-55Z-A93

MY1B32-60HZ-M9BL

MY1B32-65AZ

MY1B32-65AZ-M9NL

MY1B32-65Z

MY1B32-1000A7Z-M9BW

MY1B32-1000AHZ-M9BWL

MY1B32-1000ALZ

MY1B32-1000ALZ-M9BL

MY1B32-1000AZ-A93

MY1B32-1000AZ-A93L

MY1B32-1000AZ-M9B

MY1B32-1000AZ-M9BAL

MY1B32-1000H6H7Z-M9B

MY1B32-1000H6H7Z-M9BV

MY1B32-1000H6Z

MY1B32-1000H6Z-M9BL

MY1B32-1000H7H6Z

MY1B32-1000H7SZ

MY1B32-1000H7Z

MY1B32-1000H7Z-M9BL

MY1B32-1000H7Z-M9NVL

MY1B32-1000HH6Z

MY1B32-1000HH6Z-A93L

MY1B32-1000HLZ

MY1B40-50HZ

MY1B40-50LZ-M9BVL

MY1B40-60LZ

MY1B40-60LZ-A93L

MY1B40-70H6Z-M9BASBPC

MY1B40-70H7Z-M9BASBPC

MY1B40-75Z

MY1B40-80HSZ-M9BL

MY1B40-1000ALZ

MY1B40-1000ALZ-M9BV

MY1B40-1000ALZ-M9BV3

MY1B40-1000ALZ-M9BW

MY1B40-1000ASZ

MY1B40-1000ASZ-A90

MY1B40-1000ASZ-A93

MY1B40-1000ASZ-M9BW

MY1B40-1000AZ-M9B

MY1B40-1000AZ-M9BW5

MY1B40-1000AZ-M9N

MY1B40-1000AZ-M9NL

MY1B40-1000AZ-M9PZ

MY1B40-1000H6H7Z-M9B

MY1B40-1000H6H7Z-M9BWZ3

MY1B40-1000H6HZ

MY1B40-1000H6Z

MY1B40-1000H6Z-A93L

MY1B40-1000H6Z-M9BL

MY1B40-1000H6Z-M9BWSDPC

MY1B40-1000H6Z-M9N

MY1B40-1000H6Z-M9NL

MY1B40-50LZ-M9BVL

MY1B40-60LZ

MY1B40-60LZ-A93L

MY1B40-70H6Z-M9BASBPC

MY1B40-70H7Z-M9BASBPC

MY1B40-75Z

MY1B40-80HSZ-M9BL

MY1B40-1000ALZ

MY1B40-1000ALZ-M9BV

MY1B40-1000ALZ-M9BV3

MY1B40-1000ALZ-M9BW

MY1B40-1000ASZ

MY1B40-1000ASZ-A90

MY1B40-1000ASZ-A93

MY1B40-1000ASZ-M9BW

MY1B40-1000AZ-M9B

MY1B40-1000AZ-M9BW5

MY1B40-1000AZ-M9N

MY1B40-1000AZ-M9NL

MY1B40-1000AZ-M9PZ

MY1B40-1000H6H7Z-M9B

MY1B40-1000H6H7Z-M9BWZ3

MY1B40-1000H6HZ

MY1B40-1000H6Z

MY1B40-1000H6Z-A93L

MY1B40-1000H6Z-M9BL

MY1B40-1000H6Z-M9BWSDPC

MY1B40-1000H6Z-M9N

MY1B40-1000H6Z-M9NL