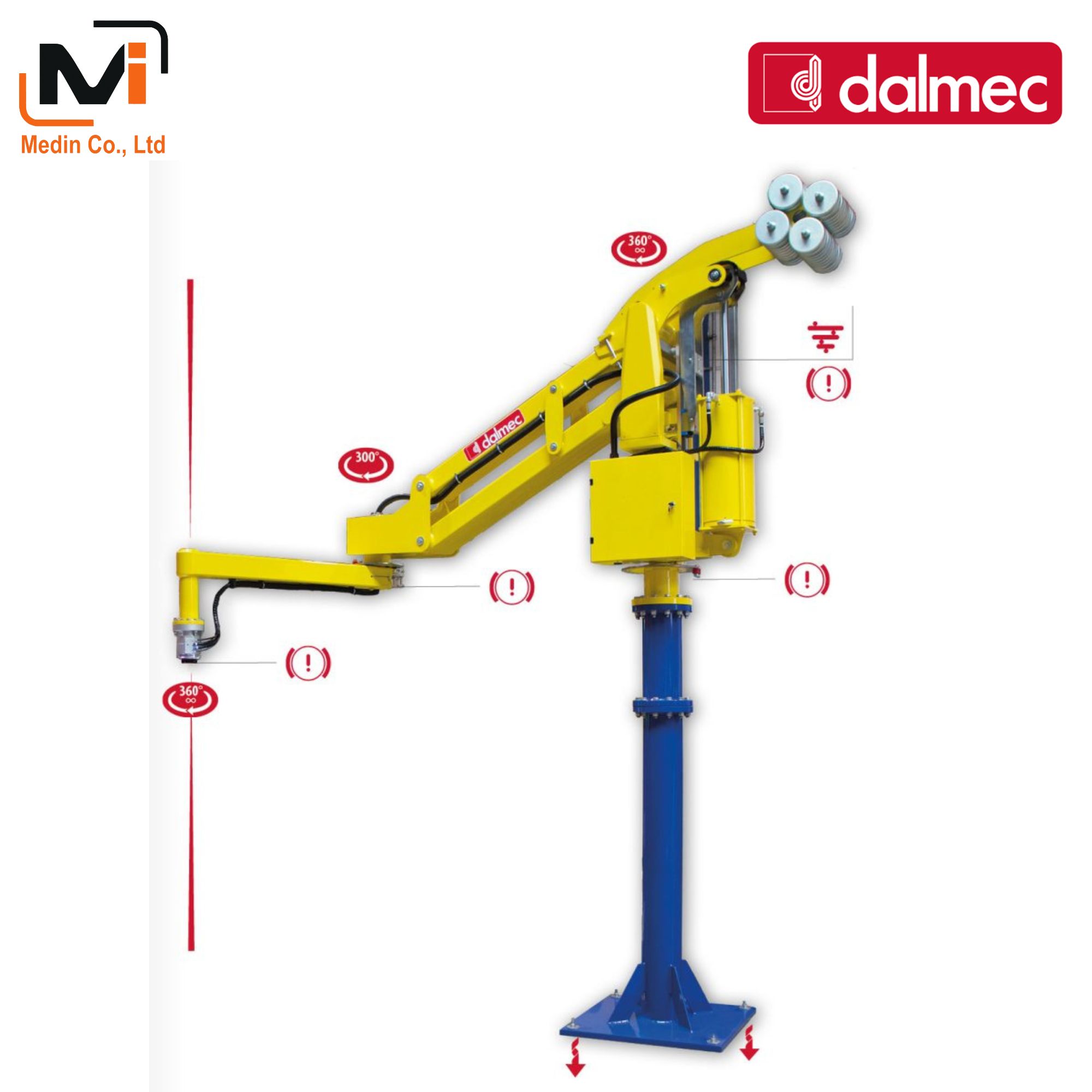

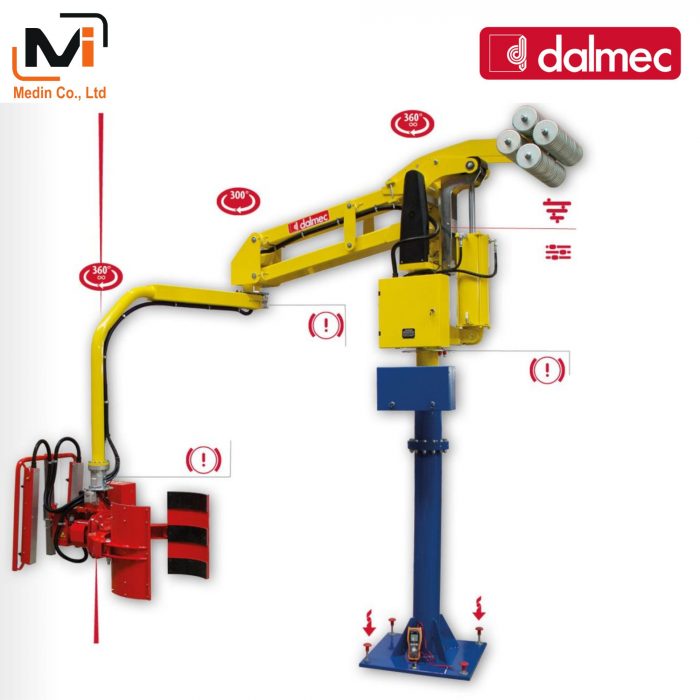

| Fixed plate for floor anchoring | Autostable base-plate for forklift truck | Autostable base-plate for pallet truck |

Maxipartner Manipulators With Rigid Arms – Tay Trợ Lực Dalmec

Max weight capacity: 900 kg

Max working radius: 4500 mm

Vertical lift: 2200 mm

Working pressure: 0.7 ÷ 0.8 Mpa

Control system: solely pneumatic

Max vertical lifting speed: 0,5 meters/second

Noise level: <70 dB

Downloads

Maxipartner Manipulators With Rigid Arms – Tay Trợ Lực Dalmec

Features

Max working radius: 4500 mm

Vertical lift: 2200 mm

Working pressure: 0.7 ÷ 0.8 Mpa

Control system: solely pneumatic

Supply: filtrated compressed-air (40 µm), not lubricated

Max vertical lifting speed: 0,5 meters/second

Working temperature: from +0° to +45° C

Noise level: <70 dB

Consumption: from 100 Nl ÷ 400 Nl per working cycle

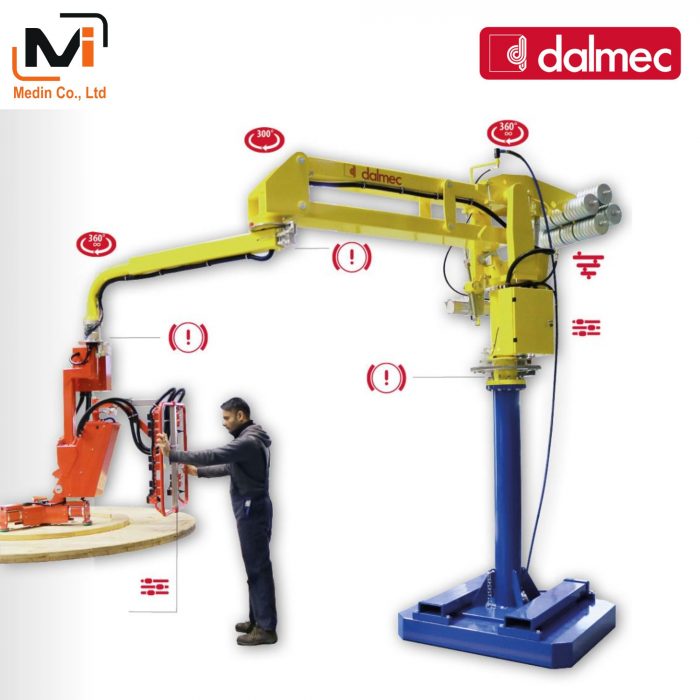

Rotations: – constant 360° on the column and tooling axis – 300° on the intermediate axis

Execution

- Atex Column

- Atex Fixed Overhead

- Atex Overhead Running

- Column

- Fixed Overhead

- Overhead Running

Description of the Manipulator

MANIPULATOR WITH ARTICULATED ARMS MAXIPARTNER EQUO ME

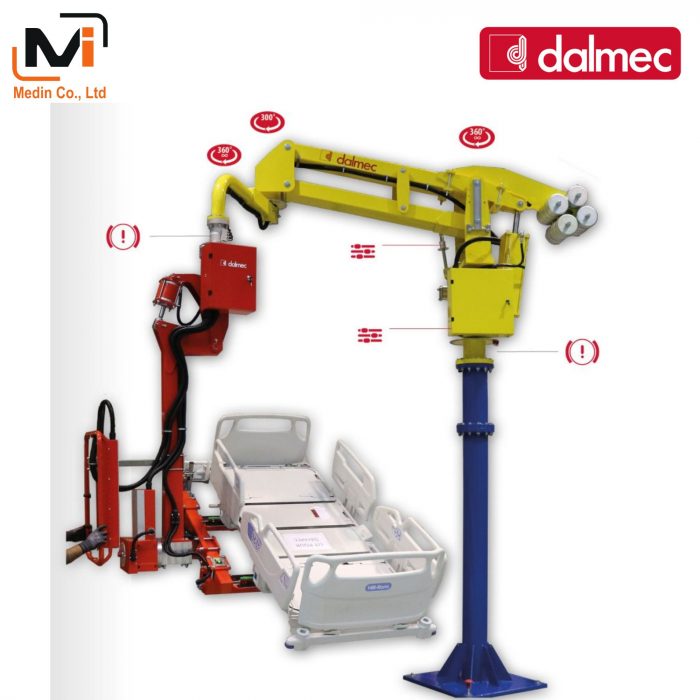

Pneumatic Manipulator MAXIPARTNER EQUO ME with articulated arms, equipped with special gripping tools, is suitable to handle heavy (max 900 kg) and also off-set loads, in any direction, allowing the operator to work with the minimum effort in good ergonomic and safety conditions.

Its slim and strong structure eliminates the “drifting” effect.

OPERATION

A pneumatic cylinder fed with compressed-air, combined with a transmission lever system, provides balance to the load weight applied.

The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced.

The operator can change the load level simply operating a pneumatic control lever.

Anchorage systems to the floor for the column mounted Manipulators

Anchor flange

The pneumatic manipulator fixed overhead version allows to eliminate any floor obstructions.

The flange of the Manipulator is supplied with holes for the anchoring with screws to a strong plate to the ceiling or to a shelf.

All movements are free and are obtained with minimum effort by the direct action of the operator on the gripping tooling or on the load.

Tracking system

Anchor

The Manipulator is supplied with an overhead trolley to run in a tracking system.

Tracking system

The tracking system is composed of two opposite aluminium U sections with connecting and stiffening ribs,complete with attachment points for an overhead suspension and end buffers. The junction between the various parts is done with screws.

Attachment

The attachment of the tracking system to the supporting structure is carried out by means of rods and suspension brackets

Application

Polyurethane blocks

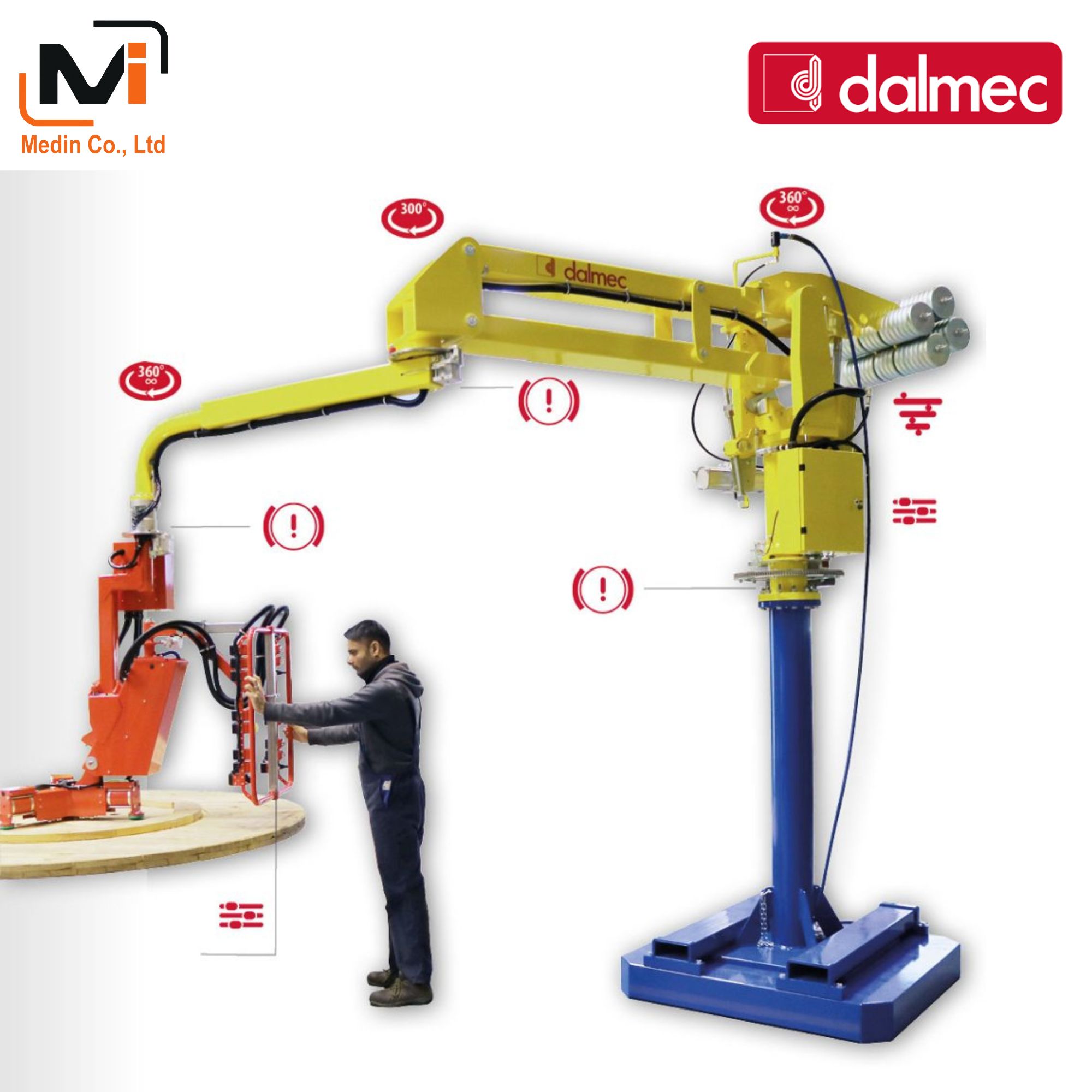

Dalmec manipulator Maxipartner, column mounted version for handling polyurethane blocks.

Equipped with a robust pinch jaws gripping device, it safely handles loads of varying weights and dimensions.

The use of telescopic controls ensures the operator always maintains correct posture, making each handling phase smooth and effortless.

The Maxipartner manipulator has a maximum weight capacity of 900 kg, with a reach of 4500 mm.

Our manipulators can be configured with different types of gripping devices, designed to lift, rotate, and tilt products of any shape, size, and material, ensuring maximum precision and control in every operation.

Our manipulators allow you to lift and move your products with the utmost precision.

Dalmec constantly seeks innovative solutions to allow the handling of manufactured goods in the absence of weight, always respecting ergonomic standards and the customer’s production needs.

Maxipartner column-mounted manipulator with self-centering pinch jaws tooling for handling large polyurethane blocks.

Panels lifter

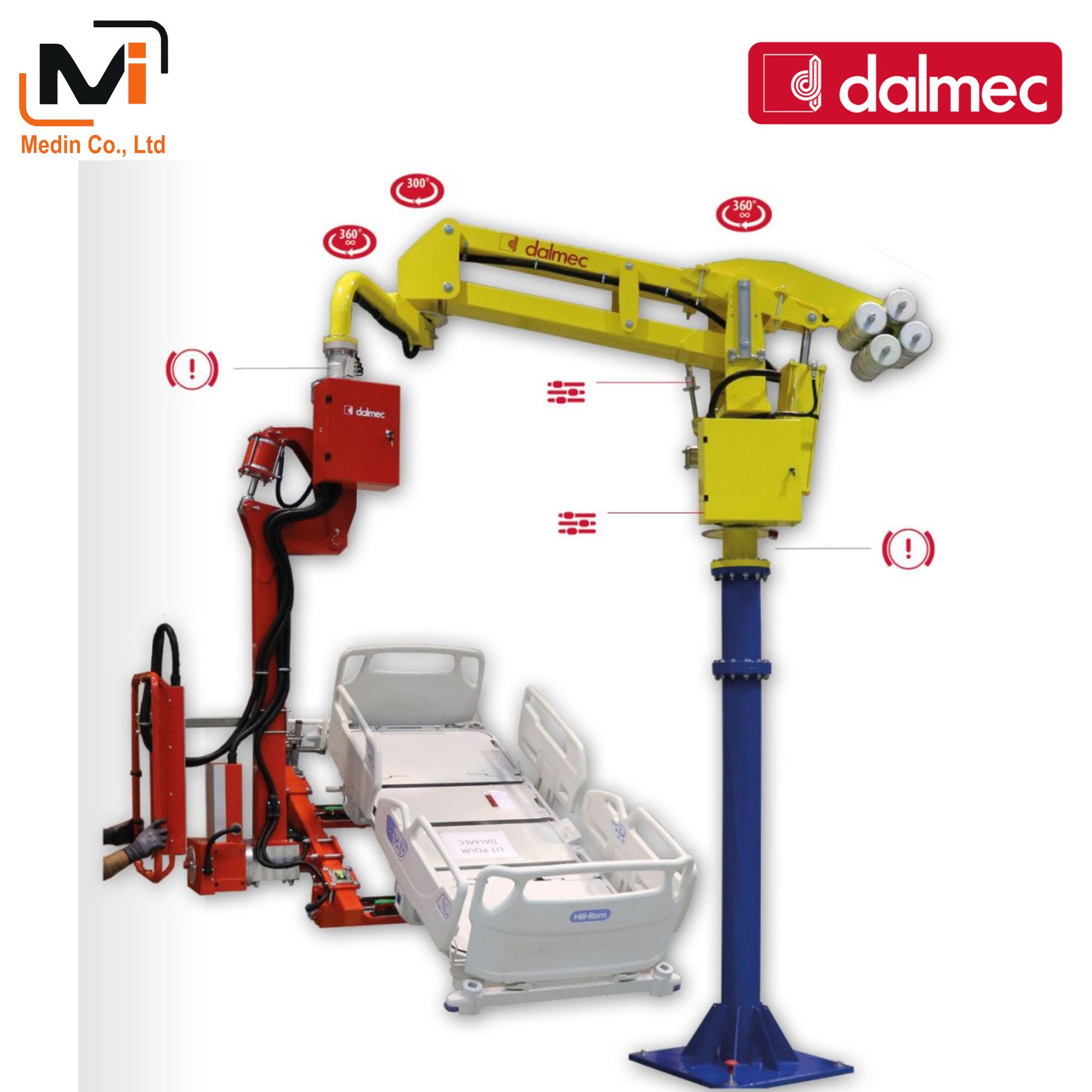

Maxipartner Equo is an articulated-arm lifter, designed by Dalmec to handle extremely heavy loads, eliminating any effort for the operator.

With a maximum capacity of 900 kg, it enables the lifting and handling of heavy loads in a fluid and precise manner. Thanks to its ergonomics design, it protects the user from injuries and allows a correct posture to be maintained during use.

Mounted on a column with a portable baseplate, it can be used in various assembly stations. It has a maximum range of action of 4500 mm and its shape and dimensions can be customized to adapt it to various work environments.

Have a look at our Maxipartner Equo manipulator in action, moving a van floor. We have designed a specially shaped gripping tooling that allows to align, rotate and tilt the floor, so as to insert it into the vehicle with safe and precise movements.

Like all Dalmec manipulators, Maxipartner is also designed and manufactured according to UNI EN standards, in compliance with CE – Atex directives and all safety indicators. We are able to create ad hoc industrial manipulators for every type of need, guaranteeing safety and maximum efficiency for your company.

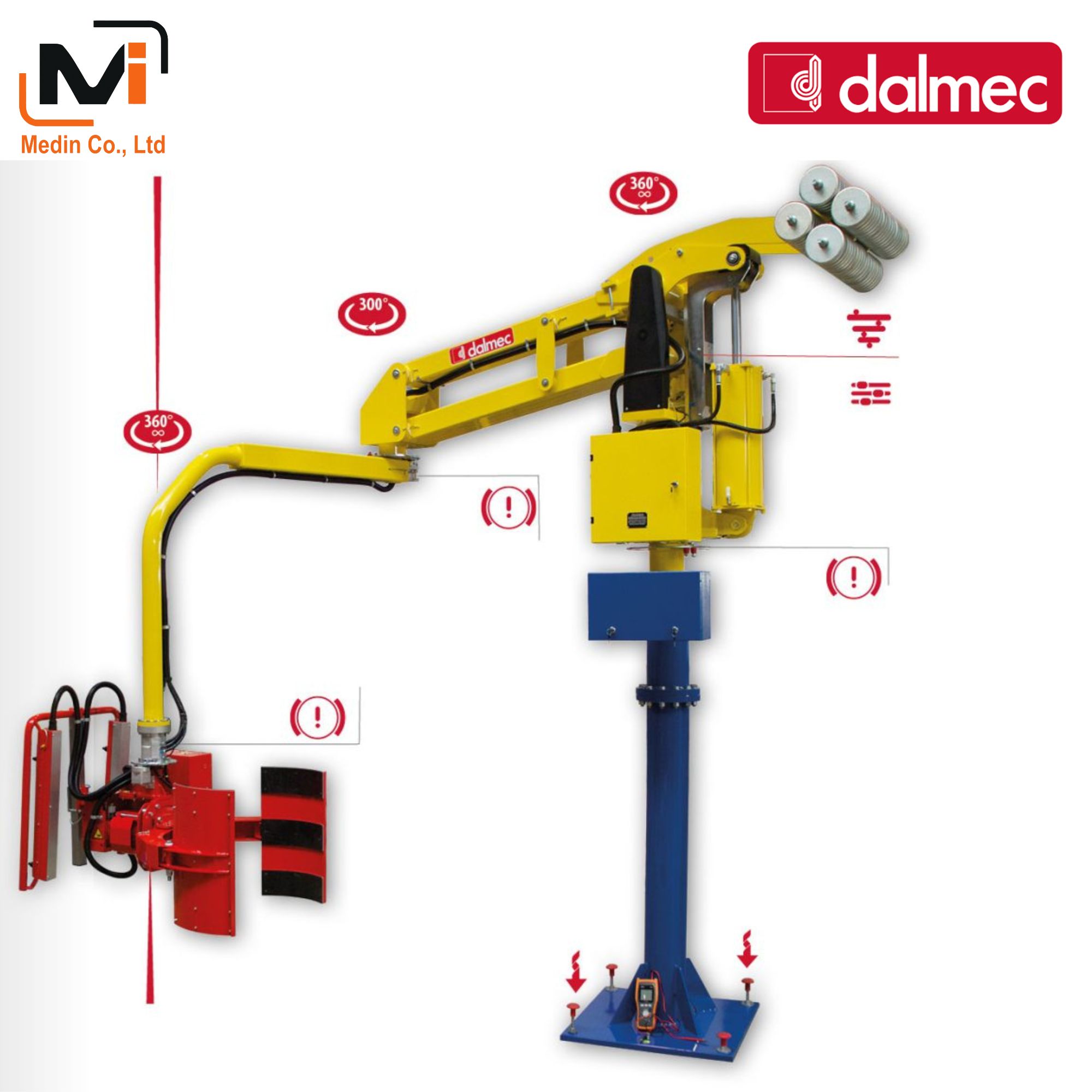

Handling device for wooden panels

Handling device for wooden panels.

Mandrel gripping system Dalmec mounted on Manipulator Maxipartner type for handling and pneumatic tilting of wooden panels.

Dalmec is present in companies all over the world. Dalmec engineers and consultants have the necessary know-how to work with you during the whole process, from conception and design to the implementation of a new sector solution.

The main purpose of DALMEC manipulators is to assist the customer and give him support to reduce the weight of his workload and to enable him to work safely, efficiently and precisely. DALMEC continuously strives every day to find the best solution to allow the handling of any kind of product without any effort in accordance with the ergonomic criteria.

Dalmec mandrel gripping system mounted on Manipulator Maxipartner type for lifting and pneumatic inclination of wooden panels.

Handling systems for reels of insulation material

Handling systems for reels of insulation material Dalmec or Manipulator

Manipulator Maxipartner MXC column mounted version provided with a portable baseplate, custom-built for lifting reels of insulating material. The base-plate allows an easy and fast use of the Manipulator in more workplaces. The gripping system with interchangeable expanding mandrel allows to lift reels of different sizes, a special device prevents the sliding out of the reel during the inclination phase. The multi-position controls are telescopic and allow the operator to position the reel at great heights. The rotation of the manipulator around the column axis is servo-assisted in case of handling of particularly heavy and cumbersome reels.

With the manipulator Maxiparter you can handle reels up to 500 kg, with a radius up to 4500 mm and a vertical lift of 2600 mm.

Manipulator Maxipartner MXC column mounted version provided with a portable baseplate, custom-built for lifting reels of insulating material.

Tại Sao Chọn Medin Company?

Medin Company chuyên cung cấp các sản phẩm chính hãng chất lượng cao.

Với kinh nghiệm sâu rộng trong ngành, chúng tôi không chỉ cung cấp sản phẩm mà với đội ngũ kĩ sư giàu kinh nghiệm, chúng tôi còn mang đến giải pháp tối ưu cho khách hàng.

Medin Company đảm bảo:

- Sản phẩm chính hãng 100%

- Giá cả cạnh tranh nhất thị trường

- Bảo hành chính hãng toàn cầu

Dịch Vụ Dùng Thử Miễn Phí

- Test tại nhà máy khách hàng: Đánh giá hiệu suất thực tế

- Không phí phát sinh: Miễn phí hoàn toàn trong 30 ngày

- Cam kết hiệu quả: Đảm bảo tăng productivity tối thiểu 30%

Khảo Sát Tận Nơi

- Site survey chuyên nghiệp: Kỹ sư senior trực tiếp khảo sát

- Báo cáo chi tiết: Phân tích toàn diện điều kiện vận hành

- Tư vấn tối ưu: Giải pháp phù hợp 100% với nhu cầu

Hỗ Trợ Kỹ Thuật 24/7

- Hotline chuyên dụng: Phản hồi trong 15 phút

- Remote support: Hỗ trợ từ xa qua

- On-site service: Kỹ sư đến tận nơi trong 24h

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.