HYG Series Hygienic Design Cylinder – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

HYG Series Hygienic Design Cylinder with an easy-to-clean format.

[Features]

· Air cylinder with improved water resistance.

· To keep the product flat, grooves for auto switches and holes for cushion needles, etc. have been eliminated.

· Approximately 5 times increase in lifespan (compared to manufacturer’s current models).

· Able to handle food grease (NSF-H1 certified).

· NBR or FKM can be selected as the external sealant material.

· Mounting part: ISO standard (VDMA) compliant (HYC).

Download

HYG Series Hygienic Design Cylinder Details – Xi Lanh Khí Nén SMC

HYG Series Hygienic Design Cylinder product image

HYG Series Hygienic Design Cylinder Specifications

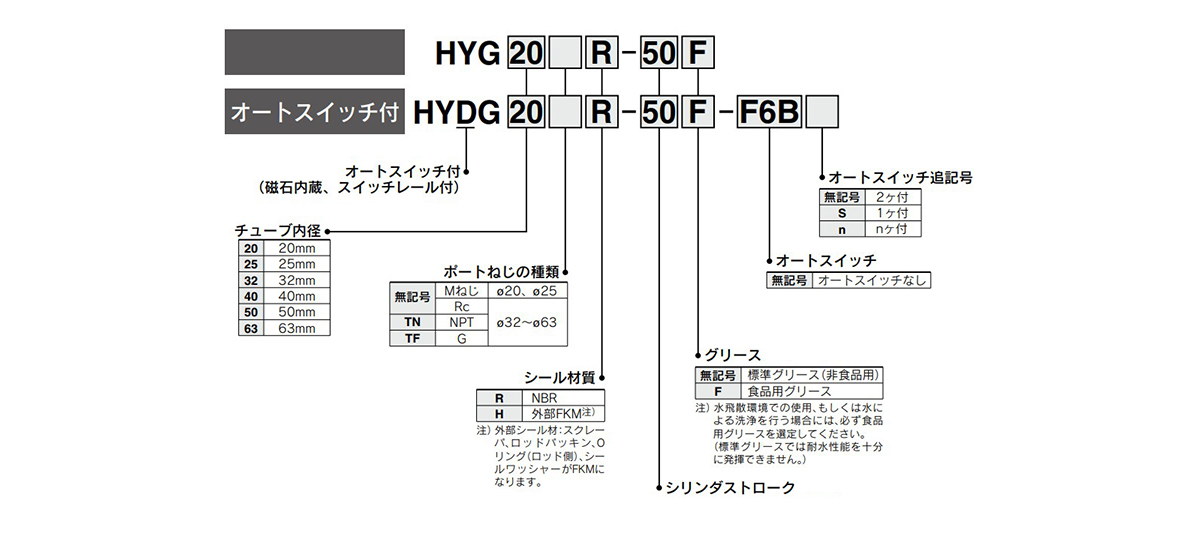

Model Number Notation

Model number examples

Specifications

| Tube Inner Diameter (mm) | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|

| Action | Double acting | |||||

| Fluid | Air | |||||

| Minimum operating pressure | 0.2 MPa | 0.15 MPa | ||||

| Maximum operating pressure | 1.0 MPa | |||||

| Proof Pressure | 1.5 MPa | |||||

| Ambient and Working Fluid Temperature | 0°C to 60°C | |||||

| Lubrication | Not required | |||||

| Piston Speed | 50 to 500 mm/s (with pressure at 1.0 MPa)* | |||||

| Cushioning | Rubber cushion | |||||

| Stroke length tolerance | (0 to +1.5) mm | |||||

*Use the product below the allowable kinetic energy.

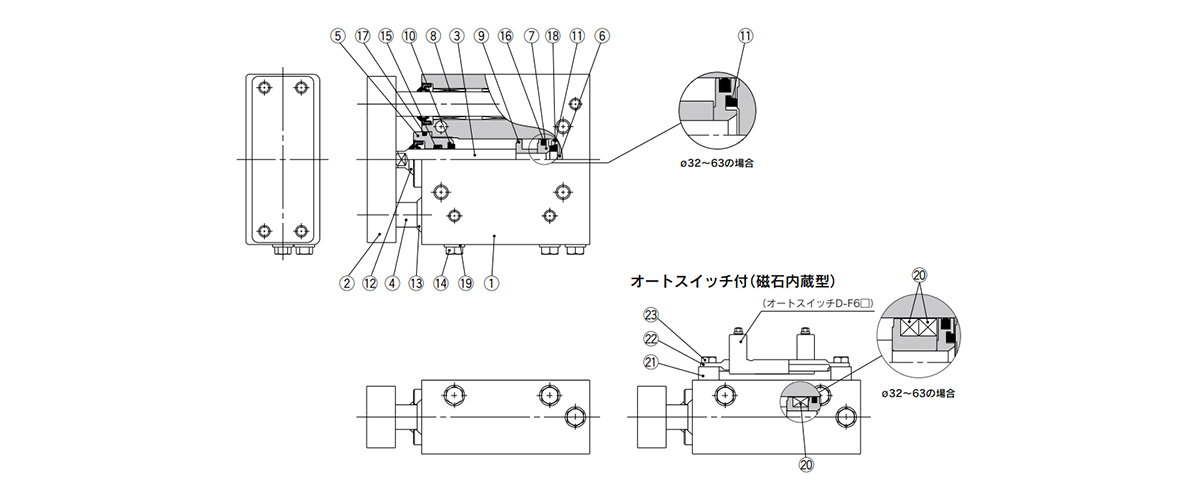

Diagram

Diagram: HYG Series Hygienic Design Cylinder

Components

| Number | Part Name | Material | Quantity | Notes |

|---|---|---|---|---|

| 1 | Body | Aluminum alloy | 1 | Anodic oxide film |

| 2 | Plate | Aluminum alloy | 1 | Anodic oxide film |

| 3 | Piston rod | Stainless steel | 1 | Hard chrome plating |

| 4 | Guide rod | Stainless steel | 2 | Special coating |

| 5 | Rod cover | Aluminum alloy | 1 | Anodic oxide film |

| 6 | Head cover | Aluminum alloy | 1 | Chromate |

| 7 | Piston | Aluminum alloy | 1 | – |

| 8 | Bushing | Stainless steel | 4 | Special coating |

| 9 | Magnetic holder | Aluminum alloy | 1 | Chromate |

| 10 | Bumper A | Resin | 1 | – |

| 11 | Damper B | Resin | 1 | – |

| 12 | Scraper (piston rod) | Stainless steel + NBR | 1 | (FKM can be selected) |

| 13 | Scraper (guide rod) | Stainless steel + NBR | 2 | (FKM can be selected) |

| 14 | Port plug | Stainless steel | 3 | – |

| 15 | Rod packing | NBR | 1 | (FKM can be selected) |

| 16 | Piston packing | NBR | 1 | – |

| 17 | O-ring (rod end) | NBR | 1 | (FKM can be selected) |

| 18 | O-ring (head end) | NBR | 1 | – |

| 19 | Seal washer | Stainless steel + NBR | 3 | (FKM can be selected) |

| 20 | Magnet | – | 1 | (Only built-in magnet) (Over ø32 [32‑mm diameter]: 2 magnets) |

| 21 | Switch rail base | Stainless steel | 2 | (Only built-in magnet) |

| 22 | Switch rail | Stainless steel | 1 | (Only built-in magnet) |

| 23 | Hexagon bolt | Stainless steel | 2 | (Only built-in magnet) |

Replacement Parts / Seal Kit

| Tube inner diameter | Part No. | Set contents |

|---|---|---|

| 20 | HYG20□-PS | Set of (15), (16), (17), (19) listed above |

| 25 | HYG25□-PS | |

| 32 | HYG32□-PS |

- *Place the seal material symbol in □.

| Symbol | Material |

|---|---|

| R | NBR |

| H | External FKM* |

- *External seal: rod seal, O-ring (rod side) and seal washer are made from FKM.

- *Seal kit includes (15), (16), (17) and (19). Order the seal kit based on the bore size.

- *Since the seal kit does not include a grease pack, order it separately.

Grease package (food compatible grease): GR-H-010 (10 g)

Grease package (standard grease): GR-S-010 (10 g) - *To replace or repair seals of cylinder bore size 40 mm or greater, please contact the manufacturer with your request.

Please contact the manufacturer when the cylinder has to be disassembled for the purpose of replacing seals, etc.

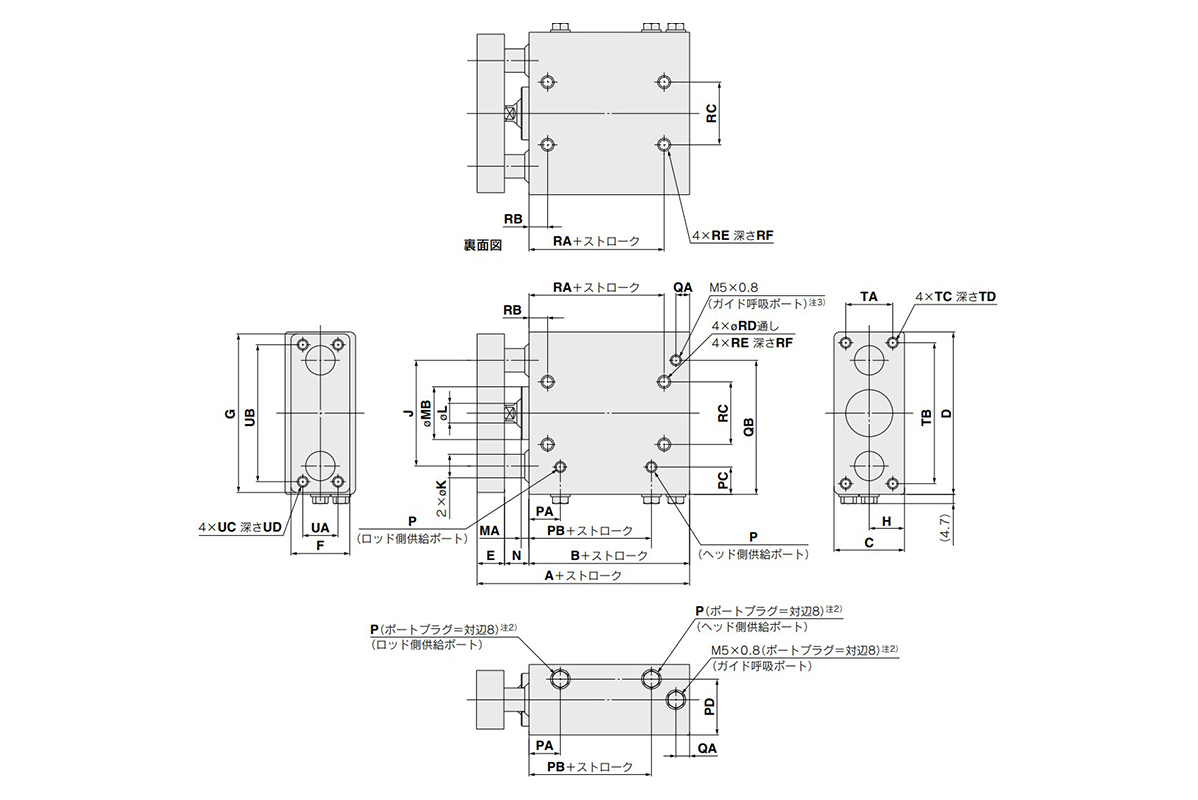

HYG Series Hygienic Design Cylinder Example Dimensions

Dimensional drawings: without auto switch HYG20, 25

(Units: mm)

| Tube inner diameter | Standard Stroke | A | B | ||||||

|---|---|---|---|---|---|---|---|---|---|

| 30 st or less | 31 to 50 st | 51 to 100 st | 101 st or more | 30 st or less | 31 to 50 st | 51 to 100 st | 101 st or more | ||

| 20 | 20, 30, 50, 100, 150, 200 | 78.5 | 88.5 | 108.5 | 128.5 | 52 | 62 | 82 | 102 |

| 25 | 86 | 96 | 116 | 136 | 56.5 | 66.5 | 86.5 | 106.5 | |

(Units: mm)

| Tube inner diameter | C | D | E | F | G | H | J | K | L | MA | MB | N | P | PA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 36 | 83 | 14 | 30 | 81 | 18 | 54 | 12 | 10 | 4 | 27 | 12.5 | M5 × 0.8 | 16 |

| 25 | 42 | 93 | 16 | 38 | 91 | 21 | 64 | 16 | 12 | 4.5 | 32 | 13.5 | M5 × 0.8 | 18 |

(Units: mm)

| Tube inner diameter | PB | PC | PD | QA | QB | RA | RB | RC | RD | RE | RF | TA | TB | TC | TD | UA | UB | UC | UD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | 32.5 | 14 | 28.5 | 7 | 68.5 | 39 | 9.5 | 32 | 5.4 | M6 × 1 | 12 | 24 | 72 | M5 × 0.8 | 13 | 18 | 70 | M5 × 0.8 | 10 |

| 25 | 34.5 | 15 | 34 | 8.5 | 78.5 | 41.5 | 9.5 | 38 | 5.4 | M6 × 1 | 12 | 29 | 80 | M6 × 1 | 14.5 | 26 | 78 | M6 × 1 | 12 |

- *The figure above shows the condition when shipped (top piping). Change the port plug position for side piping.

- *For more information on piping, refer to the specific product precautions.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Guided |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | Cushion | Rubber cushion |

HYDG20H-10

HYDG20H-10-F6BLS

HYDG20H-10-F6BS

HYDG20H-10F

HYDG20H-10F-F6BLS

HYDG20H-10F-F6BS

HYDG20H-10F-F6BZS

HYDG20H-12

HYDG20H-12-F6BS

HYDG20H-15

HYDG25H-11

HYDG25H-11-F6BS

HYDG25H-20

HYDG25H-20-F6B

HYDG25H-20-F6BL

HYDG25H-20-F6BZ

HYDG25H-20-F6NZ

HYDG25H-20-F6P

HYDG25H-20F

HYDG25H-20F-F6B

HYDG25H-20F-F6BL

HYDG32H-15F-F6BZ

HYDG32H-20

HYDG32H-20F

HYDG32H-25

HYDG32H-25-F6B

HYDG32H-25-F6NL

HYDG32H-25F

HYDG32H-25F-F6B

HYDG32H-25F-F6BL

HYDG32H-25F-F6BS

HYDG32H-25F-F6BZ

HYDG32H-25F-F6NL

HYDG40H-15F-F6BL

HYDG40H-20

HYDG40H-25

HYDG40H-25-F6BL

HYDG40H-25-F6NZ

HYDG40H-25-F6P

HYDG40H-25F

HYDG40H-25F-F6B

HYDG40H-25F-F6BL

HYDG40H-25F-F6BS

HYDG40H-25F-F6NL

HYDG40H-25F-F6NZ

HYDG50H-25-F6BL

HYDG50H-25-F6BZ

HYDG50H-25F

HYDG50H-25F-F6BL

HYDG50H-25F-F6NL

HYDG50H-25F-F6PZ

HYDG50H-30-F6BLS

HYDG50H-40-F6BL

HYDG50H-50

HYDG50H-50-F6B

HYDG50H-50-F6BL

HYDG50H-50-F6BLS

HYDG63H-15F

HYDG63H-25-F6BZ

HYDG63H-25F-F6BL

HYDG63H-35F

HYDG63H-35F-F6B

HYDG63H-50

HYDG63H-50-F6BL

HYDG63H-50-F6BLS

HYDG63H-50F

HYDG63H-50F-F6BL

HYDG63H-50F-F6BLS

HYDG63H-50F-F6NLS