Fine Lock Cylinder, Double Acting, Single Rod CLA2 Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

A standard-type double-acting, single-rod cylinder.

[Features]

· A fine lock cylinder that locks in either direction.

· A cylinder with lock that is suitable for intermediate stops, emergency stops and drop prevention.

· D-P3DW□ Series Magnetic Field Resistant 2-Color Indicator Solid State Auto Switch is mountable.

· With auto switch (CDLA2 Series: CDLA2).

*See the SMC catalog for specification details.

*Product pictures are representative images. CAD data is not supported for some model numbers.

Download

Fine Lock Cylinder, Double Acting, Single Rod CLA2 Series Specifications – Xi Lanh Khí Nén SMC

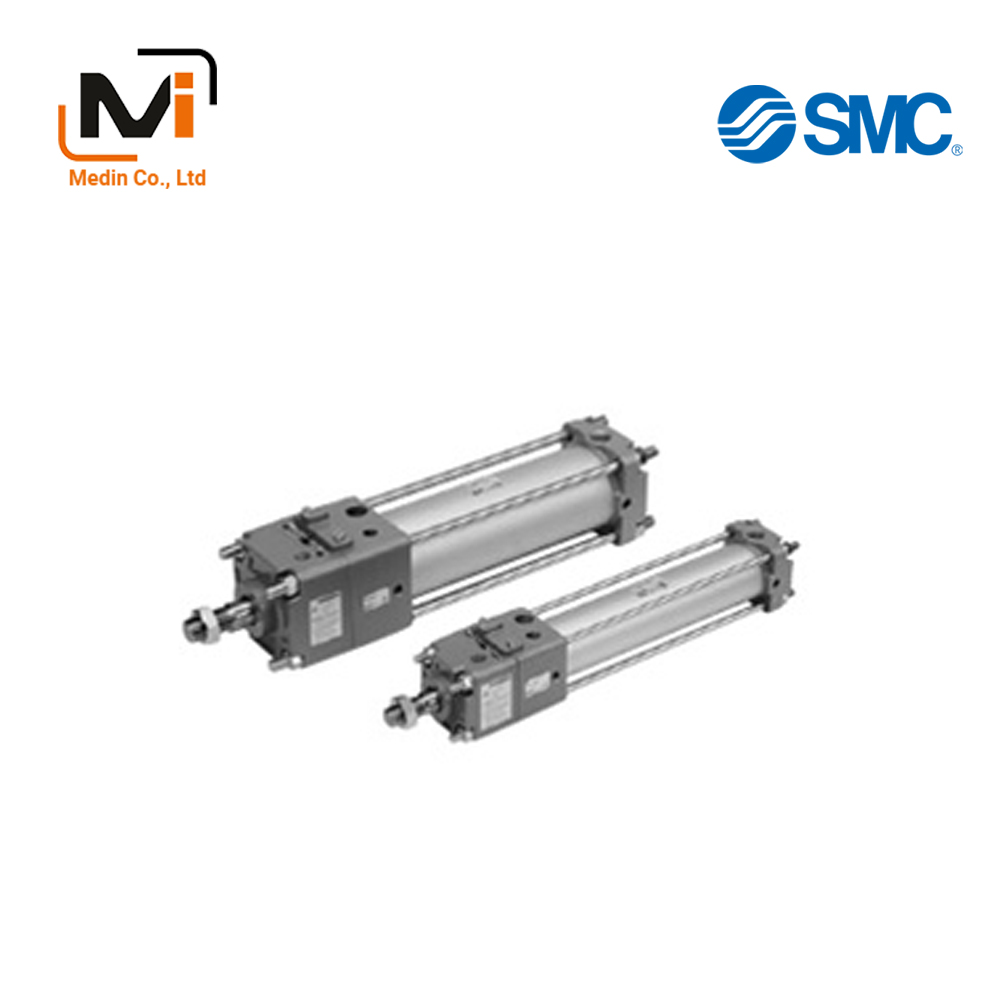

Fine Lock Cylinder, Double Acting, Single Rod CLA2 Series external appearance

| Tube Inner Diameter (mm) | 40 | 50 | 63 | 80 | 100 | 40 | 50 | 63 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Type | Non-lube | Air-hydro type | ||||||||

| Fluid | Air | Turbine oil (lock portion is air) | ||||||||

| Action | Double acting | |||||||||

| Proof Pressure | 1.5 MPa | |||||||||

| Maximum operating pressure | 1.0 MPa | |||||||||

| Minimum operating pressure | 0.08 MPa | 0.2 MPa | ||||||||

| Piston Speed | 50 to 500 mm/sec* | 15 to 300 mm/sec* | ||||||||

| Ambient and Working Fluid Temperature | Without auto switch: -10°C to 70°C With auto switch: -10°C to 60°C (no freezing) |

5°C to 60°C | ||||||||

| Cushioning | Air cushion | None | ||||||||

| Stroke Length Tolerance | Up to 250: (0 to +1.0), 251 to 1,000: (0 to +1.4), 1,001 to 1,500: (0 to +1.8) | |||||||||

| Mounting | Basic, axial foot, rod flange, head flange, single clevis, double clevis, center trunnion | |||||||||

*Constraints associated with the allowable kinetic energy are imposed on the speeds at which the piston can be locked.

Lock Specifications

| Locking Action | Spring locking (Exhaust Locking) |

Spring/Pneumatic Combination Lock |

Pneumatic locking (Pressure locking) |

|---|---|---|---|

| Unlocking pressure (MPa) | 0.3 or more | 0.1 or more | |

| Lock starting pressure (MPa) | 0.25 or less | 0.05 or less | |

| Maximum operating pressure MPa | 1.0 | 0.5 | |

| Locking Direction | Bidirectional | ||

*Adjust the switch position so that it operates upon movement to both the stroke end and backlash (2 mm) positions.

Standard Stroke

| Tube Inner Diameter (mm) | Standard stroke (mm)*1 | Long stroke (mm)*2 |

|---|---|---|

| 40 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500 | 800 |

| 50, 63 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600 | 1,200 |

| 80, 100 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 700 | ø80 (80-mm diameter): 1,400 ø100 (100-mm diameter): 1,500 |

*1: Consult with the manufacturer support center regarding intermediate strokes not listed above. Spacers are not used for intermediate strokes.

*2: Long stroke applies to the axial foot type and rod-end flange types.

CDLA2B40-25-D-M9BW

CDLA2B40-25-D-M9BWS

CDLA2B40-25-E

CDLA2B40-25-E-M9BL

CDLA2B40-25-P

CDLA2B40-35-E

CDLA2B40-35-E-A54

CDLA2B40-40-D

CDLA2B40-40-D-Z73L4

CDLA2B40-45-D

CDLA2B40-50-D

CDLA2B40-50-D-A543

CDLA2B40-50-E

CDLA2B40-50-P

CDLA2B40-60-E-Y59ALS

CDLA2B40-75-D

CDLA2B40-75-D-B54Z3

CDLA2B40-75-D-M9BWL

CDLA2B40-75-E

CDLA2B40-100-D

CDLA2B40-100-D-M9BW

CDLA2B40-100-E

CDLA2B40-100-P

CDLA2B40-100J-E

CDLA2B40-100N-D

CDLA2B40-100N-E

CDLA2B40-110-D

CDLA2B50-15-D-A53L

CDLA2B50-25-D

CDLA2B50-25-D-M9BW

CDLA2B50-25-E

CDLA2B50-25J-D

CDLA2B50-30-E

CDLA2B50-35-E

CDLA2B50-40-E

CDLA2B50-50-D

CDLA2B50-50-E

CDLA2B50-50-E-XC3CB

CDLA2B50-50-P

CDLA2B50-50N-D

CDLA2B50-60-E

CDLA2B50-62-E-J59WL

CDLA2B50-62-E-M9BWL

CDLA2B50-75-D

CDLA2B50-75-E

CDLA2B50-75-E-A54

CDLA2B50-75-E-A534

CDLA2B50-75-P

CDLA2B50-75JN-E

CDLA2B50-80-E

CDLA2B50-80-E-M9BA

CDLA2B50-80-E-M9BAL

CDLA2B50-80-E-Y7BAL

CDLA2B50-80-P

CDLA2B63-25-P

CDLA2B63-40-P

CDLA2B63-50-D

CDLA2B63-50-D-J59WL

CDLA2B63-50-E

CDLA2B63-50-E-A54

CDLA2B63-50-E-F59

CDLA2B63-50-E-J59W

CDLA2B63-50-E-J59WL

CDLA2B63-50-E-K59

CDLA2B63-50-E-M9B

CDLA2B63-50-E-M9BW

CDLA2B63-50-P

CDLA2B63-50-P-J59WL

CDLA2B63-50J-D

CDLA2B63-60-E-M9BW

CDLA2B63-75-D

CDLA2B63-75-D-M9B

CDLA2B63-75-D-XC6

CDLA2B63-75-E

CDLA2B63-75-E-A543

CDLA2B63-75-E-M9BL3

CDLA2B63-80-D

CDLA2B63-85-E

CDLA2B63-1000-D

CDLA2B63-1000-D-A53

CDLA2B80-25-E

CDLA2B80-25-E-M9BWL

CDLA2B80-25-P

CDLA2B80-40-D

CDLA2B80-40-E

CDLA2B80-45-D

CDLA2B80-45-D-B54Z

CDLA2B80-45-E

CDLA2B80-45K-D

CDLA2B80-50-D

CDLA2B80-50-D-M9B

CDLA2B80-50-D-M9BWL

CDLA2B100-20-E

CDLA2B100-25-D

CDLA2B100-25-D-F5PL

CDLA2B100-25-E

CDLA2B100-35-D

CDLA2B100-50-D

CDLA2B100-50-E

CDLA2B100-50N-E-M9BL

CDLA2B100-60-E

CDLA2B100-75-D

CDLA2B100-75-D-F5PL3

CDLA2B100-75-E

CDLA2B100-75-E-A54

CDLA2B100-75-P

CDLA2B100-80-D

CDLA2B100-1000-D

CDLA2B100-1000-E