Compact Guide Cylinder MGQ Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

An air cylinder with integrated guide with lateral load resistance and high non-rotating accuracy.

[Features]

· Compact design that saves space.

[Applications]

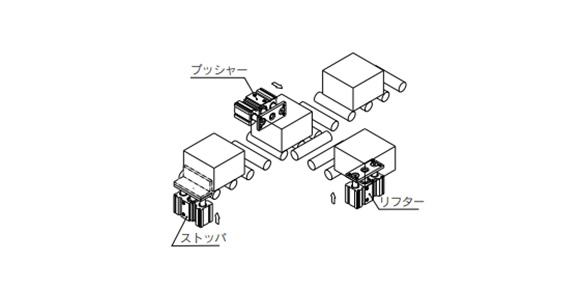

· For conveyor line stoppers and lifters.

Download

Compact Guide Cylinder MGQ Features – Xi Lanh Khí Nén SMC

Ideal for conveyor line stoppers and lifters

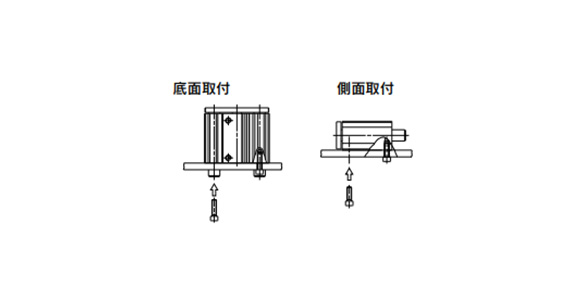

Can be mounted from 2 directions, bottom and side

Specifications

Indicator symbol

Rubber cushion

| Bearing type | Slide bearing | Ball bushing bearing | |

|---|---|---|---|

| Model | MGQM | MGQL | |

| Tube Internal Diameter (mm) | 12, 16, 20, 25, 32, 40, 50, 63, 80, 100 | ||

| Operating method | Double acting type | ||

| Applicable fluids | Air | ||

| Proof pressure | 1.5 MPa | ||

| Maximum operating pressure | 1.0 MPa | ||

| Minimum operating pressure | ø12, ø16 | 0.12 MPa | |

| ø20 to ø100 | 0.1 MPa | ||

| Ambient temperature and Working fluid temperature |

-10°C to +60°C (no freezing) | ||

| Operating piston speed | ø12 to ø63 | 50 to 500 mm/s | |

| ø80, ø100 | 50 to 400 mm/s | ||

| Cushioning | Rubber bumper at both ends | ||

| Lubrication | Non-lube | ||

| Stroke length tolerance | 0 to +1.5 mm | ||

Theoretical Output List

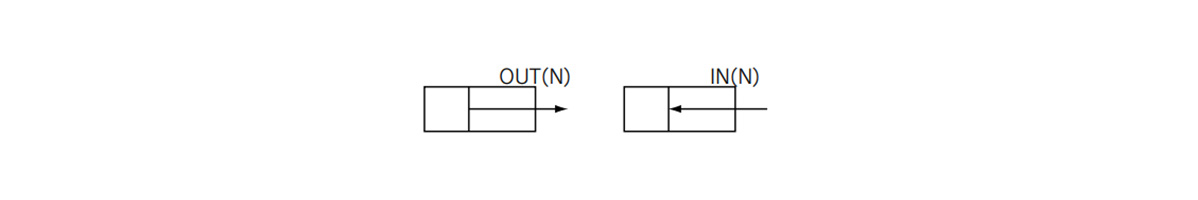

Outline drawing (OUT, IN)

| Tube I.D. (mm) |

Rod size (mm) |

Operating Direction | Piston area (mm2) |

Operating pressure (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | ||||

| 12 | 6 | OUT | 113 | 23 | 34 | 45 | 57 | 68 | 79 | 90 | 102 | 113 |

| IN | 85 | 17 | 26 | 34 | 43 | 51 | 60 | 68 | 77 | 85 | ||

| 16 | 8 | OUT | 201 | 40 | 60 | 80 | 101 | 121 | 141 | 161 | 181 | 201 |

| IN | 151 | 30 | 45 | 60 | 76 | 91 | 106 | 121 | 136 | 151 | ||

| 20 | 10 | OUT | 314 | 63 | 94 | 126 | 157 | 188 | 220 | 251 | 283 | 314 |

| IN | 236 | 47 | 71 | 94 | 118 | 142 | 165 | 189 | 212 | 236 | ||

| 25 | 12 | OUT | 491 | 98 | 147 | 196 | 246 | 295 | 344 | 393 | 442 | 491 |

| IN | 378 | 76 | 113 | 151 | 189 | 227 | 265 | 302 | 340 | 378 | ||

| 32 | 16 | OUT | 804 | 161 | 241 | 322 | 402 | 482 | 563 | 643 | 724 | 804 |

| IN | 603 | 121 | 181 | 241 | 302 | 362 | 422 | 482 | 543 | 603 | ||

| 40 | 16 | OUT | 1,257 | 251 | 377 | 503 | 629 | 754 | 880 | 1,006 | 1,131 | 1,257 |

| IN | 1,056 | 211 | 317 | 422 | 528 | 634 | 739 | 845 | 950 | 1,056 | ||

| 50 | 20 | OUT | 1,963 | 393 | 589 | 785 | 982 | 1,178 | 1,374 | 1,570 | 1,767 | 1,963 |

| IN | 1,649 | 330 | 495 | 660 | 825 | 990 | 1,154 | 1,319 | 1,484 | 1,649 | ||

| 63 | 20 | OUT | 3,117 | 623 | 935 | 1,247 | 1,559 | 1,870 | 2,182 | 2,494 | 2,805 | 3,117 |

| IN | 2,803 | 561 | 841 | 1,121 | 1,402 | 1,682 | 1,962 | 2,242 | 2,523 | 2,803 | ||

| 80 | 25 | OUT | 5,027 | 1,005 | 1,508 | 2,011 | 2,514 | 3,016 | 3,519 | 4,022 | 4,524 | 5,027 |

| IN | 4,536 | 907 | 1,361 | 1,814 | 2,268 | 2,722 | 3,175 | 3,629 | 4,082 | 4,536 | ||

| 100 | 30 | OUT | 7,854 | 1,571 | 2,356 | 3,142 | 3,927 | 4,712 | 5,498 | 6,283 | 7,069 | 7,854 |

| IN | 7,147 | 1,429 | 2,144 | 2,859 | 3,574 | 4,288 | 5,003 | 5,718 | 6,432 | 7,147 | ||

Precautions

Theoretical output (N) = Pressure (MPa) × Piston area (mm2)

Operating Conditions

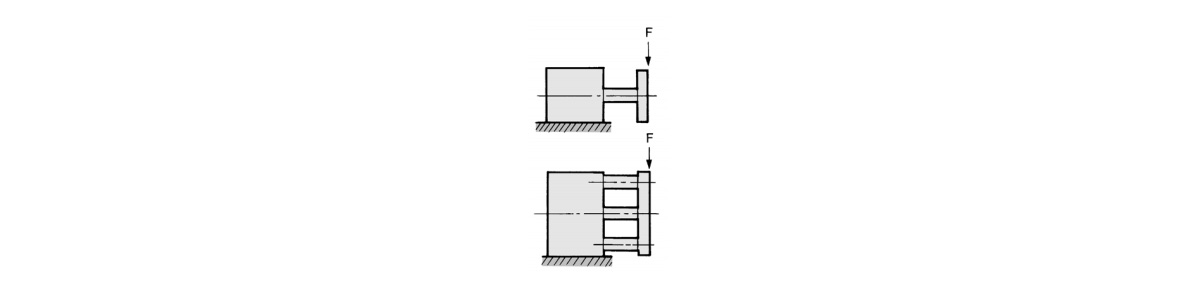

Allowable lateral load (ordinary load)

Allowable lateral load (ordinary load) outline drawing

| Tube I.D. (mm) |

Bearing type | Stroke (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | ||

| 12 | MGQM | 21 | 18 | – | 15 | 13 | 12 | 9 | 8 | – | – | – | – |

| MGQL | 27 | 22 | – | 17 | 21 | 19 | 15 | 13 | – | – | – | – | |

| 16 | MGQM | 34 | 28 | – | 25 | 22 | 19 | 15 | 13 | – | – | – | – |

| MGQL | 38 | 30 | – | 26 | 37 | 33 | 28 | 23 | – | – | – | – | |

| 20 | MGQM | – | 51 | – | 44 | 38 | 34 | 57 | 49 | 42 | 37 | 33 | 30 |

| MGQL | – | 55 | – | 47 | 78 | 69 | 53 | 44 | 30 | 26 | 23 | 21 | |

| 25 | MGQM | – | 70 | – | 60 | 53 | 47 | 77 | 65 | 56 | 49 | 44 | 40 |

| MGQL | – | 71 | – | 61 | 77 | 72 | 59 | 51 | 42 | 36 | 32 | 29 | |

| 32 | MGQM | – | – | 196 | – | – | 167 | 137 | 108 | 87 | 77 | 69 | 63 |

| MGQL | – | – | 88 | – | – | 59 | 275 | 216 | 156 | 136 | 121 | 109 | |

| 40 | MGQM | – | – | 196 | – | – | 167 | 137 | 108 | 87 | 77 | 69 | 63 |

| MGQL | – | – | 88 | – | – | 59 | 275 | 216 | 156 | 136 | 121 | 109 | |

| 50 | MGQM | – | – | 294 | – | – | 255 | 215 | 176 | 138 | 123 | 111 | 101 |

| MGQL | – | – | 137 | – | – | 88 | 392 | 313 | 207 | 182 | 162 | 146 | |

| 63 | MGQM | – | – | 294 | – | – | 255 | 215 | 176 | 138 | 123 | 111 | 101 |

| MGQL | – | – | 137 | – | – | 88 | 392 | 313 | 207 | 182 | 162 | 146 | |

| 80 | MGQM | – | – | 353 | – | – | 304 | 255 | 206 | 168 | 151 | 137 | 126 |

| MGQL | – | – | 235 | – | – | 157 | 863 | 686 | 465 | 411 | 368 | 333 | |

| 100 | MGQM | – | – | 539 | – | – | 470 | 412 | 343 | 278 | 252 | 230 | 211 |

| MGQL | – | – | 470 | – | – | 313 | 1,370 | 1,070 | 708 | 627 | 562 | 509 | |

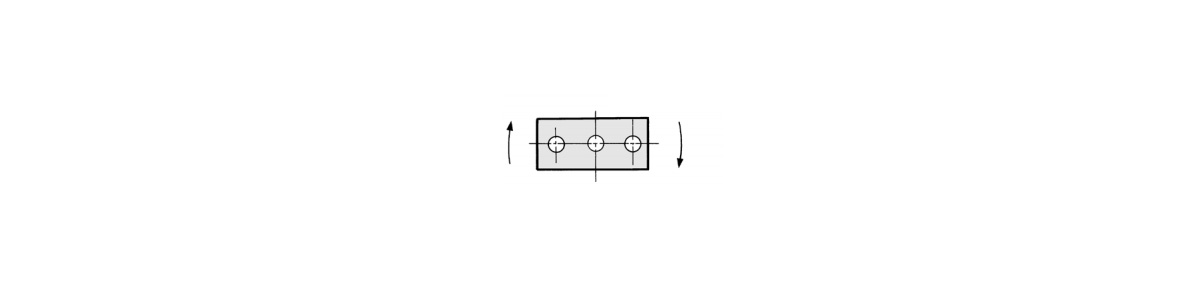

Allowable rotational torque of plate

Torque: T (N·m)

| Tube I.D. (mm) |

Bearing type | Stroke (mm) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 25 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | ||

| 12 | MGQM | 0.29 | 0.24 | – | 0.21 | 0.18 | 0.16 | 0.13 | 0.10 | – | – | – | – |

| MGQL | 0.48 | 0.39 | – | 0.31 | 0.37 | 0.33 | 0.27 | 0.23 | – | – | – | – | |

| 16 | MGQM | 0.51 | 0.43 | – | 0.35 | 0.31 | 0.27 | 0.23 | 0.19 | – | – | – | – |

| MGQL | 0.73 | 0.58 | – | 0.48 | 0.71 | 0.64 | 0.53 | 0.44 | – | – | – | – | |

| 20 | MGQM | – | 0.91 | – | 0.78 | 0.71 | 0.63 | 1.04 | 0.88 | 0.77 | 0.68 | 0.60 | 0.55 |

| MGQL | – | 1.26 | – | 1.06 | 1.77 | 1.58 | 1.22 | 1.01 | 0.69 | 0.60 | 0.53 | 0.48 | |

| 25 | MGQM | – | 1.53 | – | 1.31 | 1.16 | 1.03 | 1.68 | 1.42 | 1.24 | 1.09 | 0.98 | 0.88 |

| MGQL | – | 1.96 | – | 1.69 | 2.16 | 2.00 | 1.65 | 1.41 | 1.18 | 1.01 | 0.90 | 0.81 | |

| 32 | MGQM | – | – | 3.92 | – | – | 2.94 | 2.45 | 3.46 | 1.72 | 1.53 | 1.37 | 1.24 |

| MGQL | – | – | 1.96 | – | – | 0.98 | 5.88 | 4.41 | 3.12 | 2.72 | 2.42 | 2.18 | |

| 40 | MGQM | – | – | 4.41 | – | – | 3.43 | 2.94 | 2.45 | 1.94 | 1.72 | 1.54 | 1.40 |

| MGQL | – | – | 2.45 | – | – | 1.47 | 6.37 | 5.39 | 3.51 | 3.06 | 2.72 | 2.45 | |

| 50 | MGQM | – | – | 7.35 | – | – | 5.88 | 4.90 | 4.41 | 3.43 | 3.06 | 2.77 | 2.52 |

| MGQL | – | – | 3.43 | – | – | 2.20 | 10.78 | 8.33 | 5.18 | 4.55 | 4.05 | 3.65 | |

| 63 | MGQM | – | – | 7.84 | – | – | 6.37 | 5.39 | 4.90 | 3.77 | 3.37 | 3.04 | 2.77 |

| MGQL | – | – | 3.92 | – | – | 2.45 | 11.76 | 9.31 | 5.69 | 5.01 | 4.46 | 4.02 | |

| 80 | MGQM | – | – | 11.76 | – | – | 9.80 | 7.84 | 6.86 | 5.88 | 5.28 | 4.79 | 4.39 |

| MGQL | – | – | 9.31 | – | – | 5.88 | 31.36 | 24.50 | 16.28 | 14.39 | 12.88 | 11.66 | |

| 100 | MGQM | – | – | 22.54 | – | – | 19.60 | 16.66 | 14.70 | 11.81 | 10.67 | 9.74 | 8.96 |

| MGQL | – | – | 21.56 | – | – | 13.72 | 63.70 | 49.00 | 30.09 | 26.65 | 23.89 | 21.63 | |

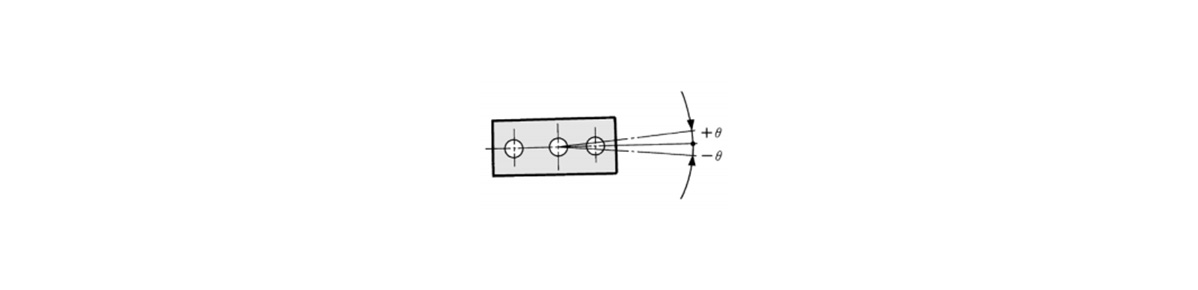

Non-rotating accuracy of plate

For non-rotating accuracy θ without load, use a value no more than the values in the table as a guide.

| Tube I.D. (mm) |

Non-rotating accuracy θ | |

|---|---|---|

| MGQM | MGQL | |

| 12 | ±0.08° | ±0.10° |

| 16 | ||

| 20 | ±0.07° | ±0.09° |

| 25 | ||

| 32 | ±0.06° | ±0.08° |

| 40 | ||

| 50 | ±0.05° | ±0.06° |

| 63 | ||

| 80 | ±0.04° | ±0.05° |

| 100 | ||

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Guided |

|---|---|---|---|---|---|

| Additional Function | Standard / With rod detent function | Environment, Applications | Standard |

MGQL16-50

MGQM12-10

MGQM12-20

MGQM12-30

MGQM12-40

MGQM12-50

MGQM16-10

MGQM16-20

MGQM16-30

MGQM16-40

MGQM16-50

MGQM16-75

MGQM16-100

MGQL32-25

MGQL32-100

MGQL40-50

MGQL40-100

MGQL20-30

MGQL20-75

MGQL20-125

MGQL20-200

MGQL25-50

MGQL25-100

MGQM20-20

MGQM20-30

MGQM20-40

MGQM20-50

MGQM20-175

MGQM25-20

MGQM25-30

MGQM25-40

MGQM25-50

MGQM25-75

MGQL40-175

MGQL50-50

MGQL63-100

MGQL80-100

MGQL100-50

MGQL100-200

MGQM32-25

MGQM32-50

MGQM32-75

MGQM32-100

MGQM32-125

MGQM40-25

MGQM40-50

MGQM40-150

MGQM40-200

MGQM50-25

MGQM50-50

MGQM50-100

MGQM50-175

MGQM63-25

MGQM80-125

MGQM100-25

MGQM100-50

MGQM100-100