Compact Cylinder, Standard Type, Double Acting, Double Rod CQSW Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

Compact Cylinder, Standard Type, Double Acting, Double Rod that that is ideal for machine designs with small space requirements.

[Features]

· Square body shape that gives you flexibility for designing machines.

· 2-way basic mounting.

· Non-rotating rod with high non-rotating accuracy.

Danh mục: AUTOMATION, Compact Cylinders - Xi Lanh Khí Nén SMC, SMC

Download

Compact Cylinder, Standard Type, Double Acting, Double Rod CQSW Series Details – Xi Lanh Khí Nén SMC

Compact Cylinder, Standard Type, Double Acting, Double Rod CQSW Series product image

Compact Cylinder, Standard Type, Double Acting, Double Rod CQSW Series Specifications

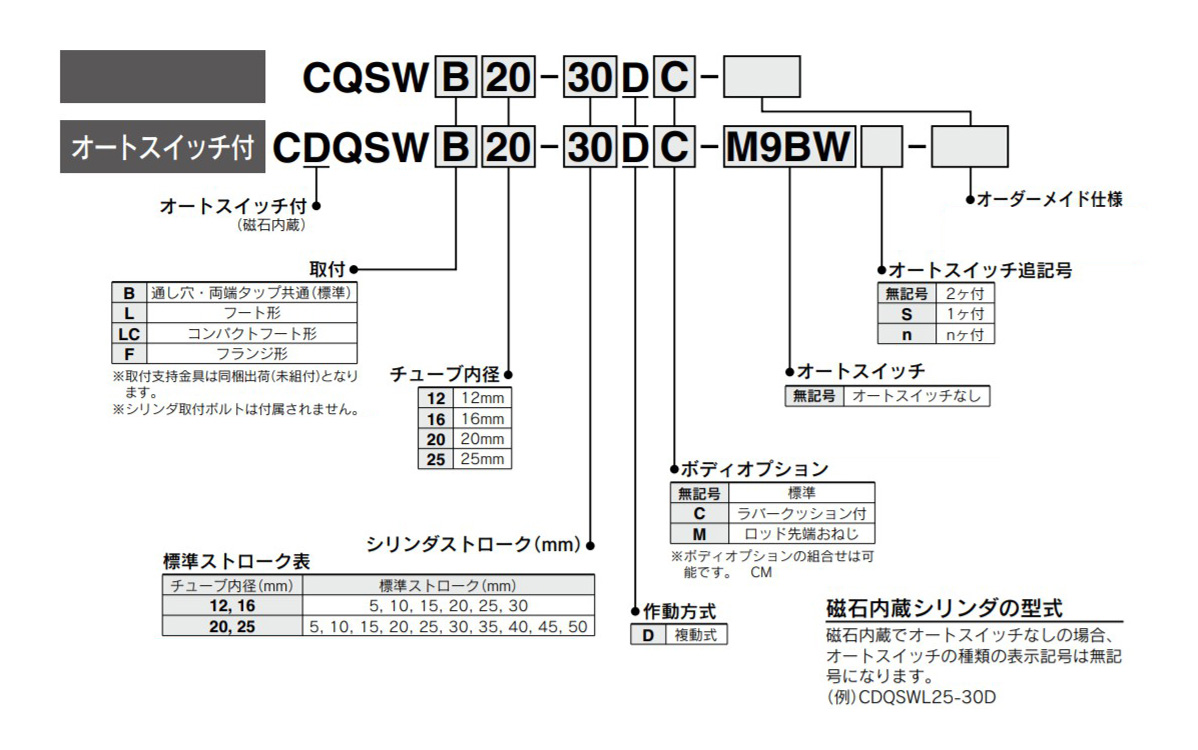

Model Number Notation

Model number example

Individual Made-to-Order Specifications

| Indicator symbol | Specifications/contents |

|---|---|

| -X235 | Change of piston rod end of double rod cylinder |

| -X271 | Fluororubber seals |

| -X633 | Intermediate stroke of double rod cylinder |

Made to order specifications

| Indicator symbol | Specifications/contents |

|---|---|

| -XA□ | Change of rod-end shape |

| -XB6 | Heat-resistant cylinder (-10 to 150°C) without an auto switch |

| -XB7 | Cold-resistant cylinder (-40 to 70°C) without an auto switch |

| -XB9 | Low speed cylinder (10 to 50 mm/s) |

| -XB10 | Intermediate stroke (using exclusive body) |

| -XB13 | Low speed cylinder (5 to 50 mm/s) |

| -XC6 | Piston rod, retaining ring, rod-end nut made of stainless steel |

| -XC36 | With boss on rod side |

| -XC85 | Grease for food processing equipment |

Standard specification

| Tube Internal Diameter (mm) | 12 | 16 | 20 | 25 | |

|---|---|---|---|---|---|

| Operating method | Double acting, double rod | ||||

| Applicable fluids | Air | ||||

| Lubrication | Not required (non-lube) | ||||

| Proof pressure | 1.5 MPa | ||||

| Maximum operating pressure | 1.0 MPa | ||||

| Minimum operating pressure | 0.07 MPa | 0.05 MPa | |||

| Ambient and working fluid temperature | Without auto switch: -10°C to 70°C (No freezing) | ||||

| With auto switch: -10°C to 60°C (No freezing) | |||||

| Cushioning | None, rubber bumper | ||||

| Rod-end thread | Female thread | ||||

| Stroke length tolerance | +1.0 mm* 0 |

||||

| Operating piston speed | 50 to 500 mm/s | ||||

| Allowable kinetic energy J | Standard type | 0.022 | 0.038 | 0.055 | 0.09 |

| With rubber bumper | 0.043 | 0.075 | 0.11 | 0.18 | |

- *Stroke length tolerance does not include the amount of bumper change.

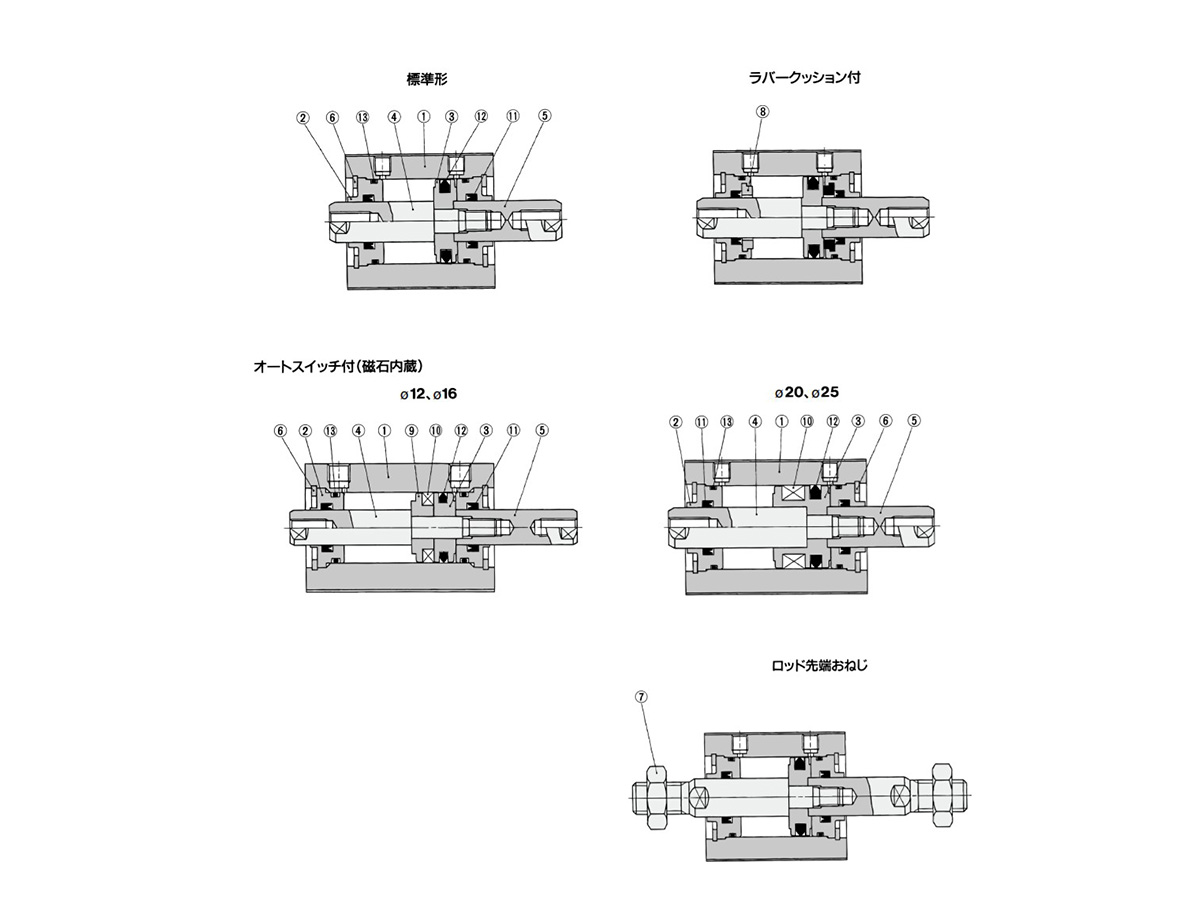

Structural drawing

Compact Cylinder, Standard Type, Double Acting, Double Rod CQSW Series Structural Drawing

Component Parts

| Number | Part name | Material | Note |

|---|---|---|---|

| 1 | Cylinder tube | Aluminum Alloy | Hard Anodize |

| 2 | Collar | Aluminum Alloy | Anodized |

| 3 | Piston | Aluminum Alloy | – |

| 4 | Piston rod A | Stainless steel | – |

| 5 | Piston rod B | Stainless steel | – |

| 6 | Retaining Ring | Carbon tool steel | Phosphate coated |

| 7 | Rod-end nut | Carbon steel | Zinc chromate |

| 8 | Dampers | Urethane | – |

| 9 | Spacer for switch | Aluminum Alloy | Chromate |

| 10 | Magnet | – | – |

| 11 | Rod Gasket | NBR | – |

| 12 | Piston Gasket | NBR | – |

| 13 | Tube gasket | NBR | – |

Replacement Parts / Seal Kit

| Tube Internal Diameter (mm) | Order number | Content |

|---|---|---|

| 12 | CQSWB12-PS | A set of (11), (12), (13) listed above |

| 16 | CQSWB16-PS | |

| 20 | CQSWB20-PS | |

| 25 | CQSWB25-PS |

- *Seal kit includes (11), (12) and (13). Order the seal kit based on each bore size.

- *The seal kit does not include a grease pack, so please order a grease pack separately.

Grease pack part number: GR-S-010 (10 g)

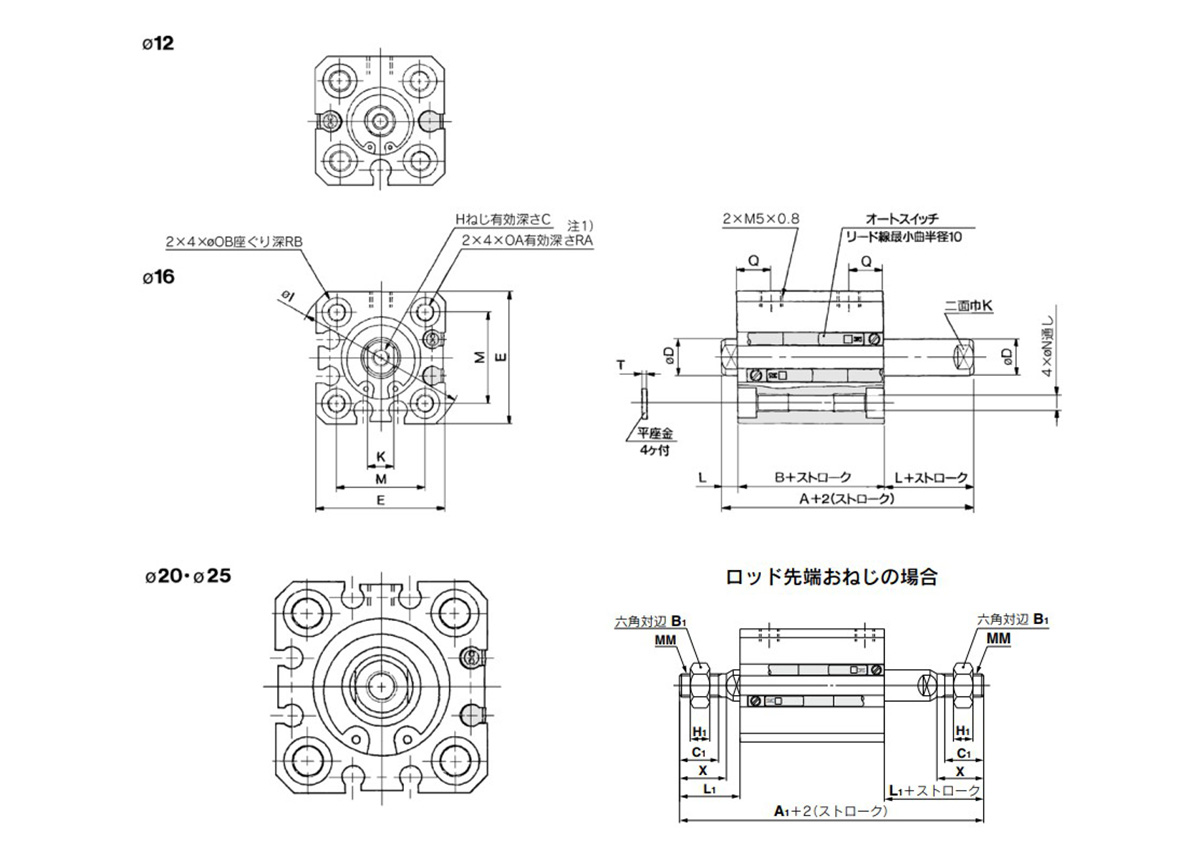

Compact Cylinder, Standard Type, Double Acting, Double Rod CQSW Series Example Dimensions

(Unit: mm)

Standard type (through-hole / both ends tapped common): CQSWB/CDQSWB dimensional drawing

Male rod end

(Unit: mm)

| Bore size (mm) |

Without auto switch | With auto switch | B1 | C1 | H1 | L1 | MM | X |

|---|---|---|---|---|---|---|---|---|

| A1 | A1 | |||||||

| 12 | 50 | 55 | 8 | 9 | 4 | 14 | M5 × 0.8 | 10.5 |

| 16 | 53 | 58 | 10 | 10 | 5 | 15.5 | M6 × 1.0 | 12 |

| 20 | 63 | 73 | 13 | 12 | 5 | 18.5 | M8 × 1.25 | 14 |

| 25 | 74 | 84 | 17 | 15 | 6 | 22.5 | M10 × 1.25 | 17.5 |

Standard type

(Unit: mm)

| Bore size (mm) |

Stroke range (mm) |

Without auto switch | With auto switch | C | D | E | H | I | K | L | M | N | OA | OB | Q | RA | RB | T | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | |||||||||||||||||

| 12 | 5 to 30 | 29 | 22 | 34 | 27 | 6 | 6 | 25 | M3 × 0.5 | 32 | 5 | 3.5 | 15.5 | 3.5 | M4 × 0.7 | 6.5 | 7.5 | 7 | 4 | 0.5 |

| 16 | 5 to 30 | 29 | 22 | 34 | 27 | 8 | 8 | 29 | M4 × 0.7 | 38 | 6 | 3.5 | 20 | 3.5 | M4 × 0.7 | 6.5 | 7.5 | 7 | 4 | 0.5 |

| 20 | 5 to 50 | 35 | 26 | 45 | 36 | 7 | 10 | 36 | M5 × 0.8 | 47 | 8 | 4.5 | 25.5 | 5.4 | M6 × 1.0 | 9 | 8 | 10 | 7 | 1 |

| 25 | 5 to 50 | 39 | 29 | 49 | 39 | 12 | 12 | 40 | M6 × 1.0 | 52 | 10 | 5 | 28 | 5.4 | M6 × 1.0 | 9 | 9 | 10 | 7 | 1 |

- *Note 1) For the following bore/stroke sizes, the through-hole is threaded: Standard type: ø20 (20‑mm diameter), ø25 (25‑mm diameter) 5 stroke.

- *Note 2) Rubber bumper type has the same dimensions as those indicated above.

- *Note 3) The positions of the width across flats are not the same on both sides.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Double rod | Main Body Shape | Plate Cylinder |

|---|---|---|---|---|---|

| Additional Function | High rigidity / high precision high class guide |

CDQSWB12-5D

CDQSWB12-5D-A90VS

CDQSWB12-5D-A93VLS

CDQSWB12-5D-A93VS

CDQSWB12-5D-A96VLS

CDQSWB12-5D-M9BV

CDQSWB12-5D-M9BV-X235

CDQSWB12-5D-M9BVL

CDQSWB12-5D-M9BVL-X235

CDQSWB12-5D-A90VS

CDQSWB12-5D-A93VLS

CDQSWB12-5D-A93VS

CDQSWB12-5D-A96VLS

CDQSWB12-5D-M9BV

CDQSWB12-5D-M9BV-X235

CDQSWB12-5D-M9BVL

CDQSWB12-5D-M9BVL-X235

CDQSWB16-5D

CDQSWB16-5D-A90VS

CDQSWB16-5D-A93VLS

CDQSWB16-5D-A93VLS-X235

CDQSWB16-5D-A93VS

CDQSWB16-5D-M9BV

CDQSWB16-5D-M9BVL

CDQSWB16-5D-M9BVL-X235

CDQSWB16-5D-M9BVLS

CDQSWB16-5D-M9BVLS-X235

CDQSWB16-5D-A90VS

CDQSWB16-5D-A93VLS

CDQSWB16-5D-A93VLS-X235

CDQSWB16-5D-A93VS

CDQSWB16-5D-M9BV

CDQSWB16-5D-M9BVL

CDQSWB16-5D-M9BVL-X235

CDQSWB16-5D-M9BVLS

CDQSWB16-5D-M9BVLS-X235

CDQSWB20-5D

CDQSWB20-5D-A90VS

CDQSWB20-5D-A93VLS

CDQSWB20-5D-A93VS

CDQSWB20-5D-M9BV

CDQSWB20-5D-M9BV-XC6

CDQSWB20-5D-M9BVL

CDQSWB20-5D-M9BVLS

CDQSWB20-5D-M9BVLS-X235

CDQSWB20-5D-M9BVS

CDQSWB20-5D-M9BVS-XB9

CDQSWB20-5D-A90VS

CDQSWB20-5D-A93VLS

CDQSWB20-5D-A93VS

CDQSWB20-5D-M9BV

CDQSWB20-5D-M9BV-XC6

CDQSWB20-5D-M9BVL

CDQSWB20-5D-M9BVLS

CDQSWB20-5D-M9BVLS-X235

CDQSWB20-5D-M9BVS

CDQSWB20-5D-M9BVS-XB9

CDQSWB25-5D

CDQSWB25-5D-A93VLS

CDQSWB25-5D-A93VS

CDQSWB25-5D-F8B

CDQSWB25-5D-M9BV

CDQSWB25-5D-M9BV-X271

CDQSWB25-5D-M9BV-XC6

CDQSWB25-5D-M9BVL

CDQSWB25-5D-M9BVL-X271

CDQSWB25-5D-M9BVL-XC6

CDQSWB25-5D-M9BVLS

CDQSWB25-5D-A93VLS

CDQSWB25-5D-A93VS

CDQSWB25-5D-F8B

CDQSWB25-5D-M9BV

CDQSWB25-5D-M9BV-X271

CDQSWB25-5D-M9BV-XC6

CDQSWB25-5D-M9BVL

CDQSWB25-5D-M9BVL-X271

CDQSWB25-5D-M9BVL-XC6

CDQSWB25-5D-M9BVLS

CDQSWB12-5D-A90VS

CDQSWB16-5D-A90VS

CDQSWB20-5D-A90VS

CDQSWB25-5D-A93VS