Compact Cylinder, Large Bore Size, Double Acting, Single Rod CQ2 Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

A space-saving cylinder designed with a short overall length. Helps to make jigs and equipment more compact.

[Features]

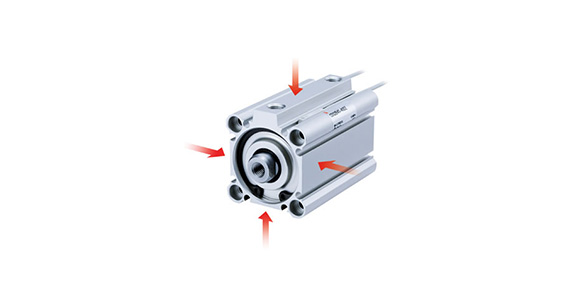

· Remodeled with a new body for more flexibility. Small auto switches can be mounted on the 4 surfaces.

· Auto switches can be mounted at any position on the 4 surfaces to best match the installation conditions. (ø12 to ø25: 2 surfaces)

· Improved design flexibility.

· The auto switch rail has been removed. A round groove for mounting small auto switches has been provided on the 4 surfaces. · Supports up to ø200.

· No projection of auto switches.

· Tube inner diameter: 125 to 200 mm.

· Action: double acting, single rod.

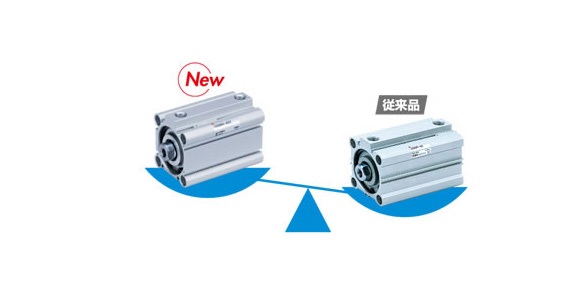

· Lightweight: Reduced by 5 to 13% (compared to conventional CQ2 Series)

· Compact large bore size.

· With auto switch.

Download

Compact Cylinder, Large Bore Size, Double Acting, Single Rod CQ2 Series Specifications – Xi Lanh Khí Nén SMC

Small Auto Switches Mountable on 4 Surfaces

Remodeled with a new body for more flexibility.

Auto switches can be mounted at any position on the 4 surfaces to best match the installation conditions.

Improved design flexibility.

ø125 to 200 (internal diameter)

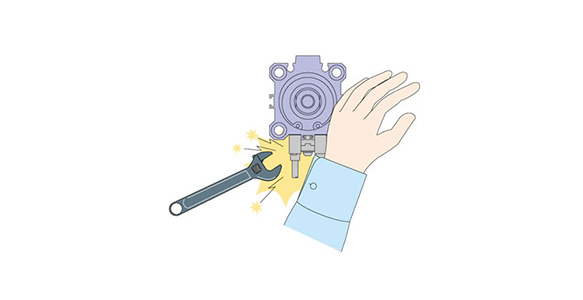

No Auto Switch Projection

Conventional product image

Prevents damage to auto switch.

Sleeves cannot get caught in the auto switch and its mounting rail, improving ease of work and safety.

Reduction in labor hours for design.

The outer dimensions of the cylinder do not change when an auto switch is mounted, so there is no need to check for interference with machinery.

Lightweight

Reduced by 5 to 13% (compared to conventional CQ2 Series).

The body strength (allowable kinetic energy, allowable load, withstand pressure, etc.) remains the same as for the conventional product. Helps contribute to a cleaner environment and ecology through a reduction in the use of aluminum, reducing CO² discharge by 1,300 t.

Conventional product comparison image

Specifications

| Tube Inner Diameter (mm) | 125 | 140 | 160 | 180 | 200 |

|---|---|---|---|---|---|

| Action | Double acting, single rod | ||||

| Fluid | Air | ||||

| Proof Pressure | 1.5 MPa | 1.05 MPa | |||

| Maximum operating pressure | 1.0 MPa | 0.7 MPa | |||

| Minimum Operating Pressure | 0.05 MPa | ||||

| Ambient and Fluid Temperature | Without auto switch: -10°C to 70°C (No freezing) With auto switch: -10°C to 60°C (No freezing) |

||||

| Lubrication | Not required (non-lubricated) | ||||

| Piston Speed | 50 to 500 mm/s | 20 to 400 mm/s | |||

| Allowable Kinetic Energy J | 7.4 | 9.8 | 12.4 | ||

| Stroke Length Tolerance | 0 to +1.4 mm | ||||

The stroke length tolerance does not include changes to the bumper.

Standard Stroke Table

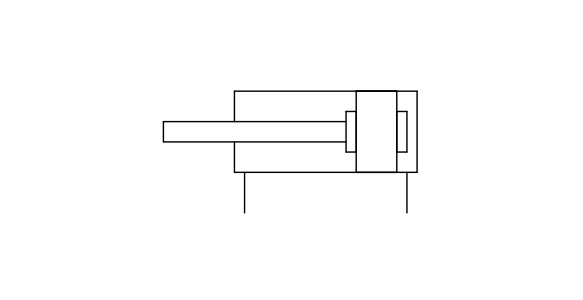

JIS symbol

Rubber bumper

| Tube Internal Diameter | Standard Stroke |

|---|---|

| 125, 140, 160 180, 200 |

10, 20, 30, 40, 50, 75, 100, 125, 150, 175, 200, 250, 300 |

(Units: mm)

Theoretical Output Table

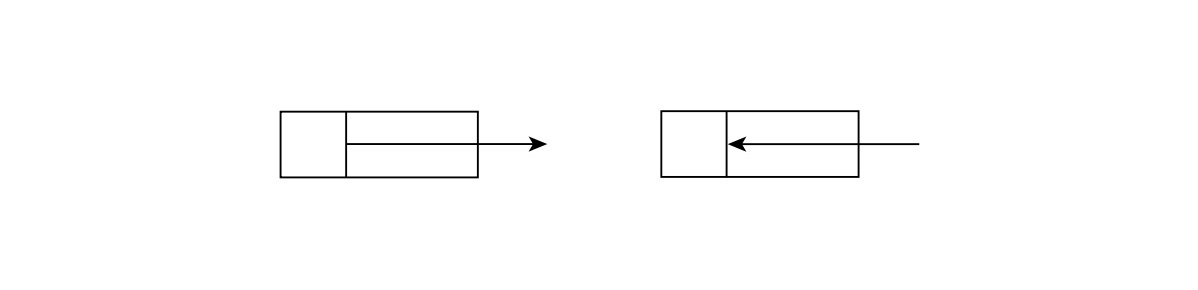

OUT/IN

| Tube Internal Diameter (mm) |

Operating Direction | Operating Pressure (MPa) | ||

|---|---|---|---|---|

| 0.3 | 0.5 | 0.7 | ||

| 125 | IN | 3,376 | 5,627 | 7,878 |

| OUT | 3,682 | 6,136 | 8,590 | |

| 140 | IN | 4,313 | 7,188 | 10,063 |

| OUT | 4,618 | 7,697 | 10,776 | |

| 160 | IN | 5,655 | 9,425 | 13,195 |

| OUT | 6,032 | 10,053 | 14,074 | |

| 180 | IN | 7,257 | 12,095 | 16,933 |

| OUT | 7,634 | 12,724 | 17,813 | |

| 200 | IN | 9,048 | 15,080 | 21,112 |

| OUT | 9,425 | 15,708 | 21,991 | |

(Unit: N)

Weight Table

Without auto switch

| Tube Inner Diameter (mm) | Cylinder Stroke (mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | |

| 125 | 5.24 | 5.48 | 5.71 | 5.94 | 6.18 | 6.76 | 7.35 | 7.93 | 8.52 | 9.10 | 9.69 | 10.86 | 12.03 |

| 140 | 6.19 | 6.44 | 6.71 | 6.98 | 7.25 | 7.90 | 8.57 | 9.23 | 9.90 | 10.56 | 11.23 | 12.55 | 13.88 |

| 160 | 8.57 | 8.88 | 9.20 | 9.52 | 9.84 | 10.64 | 11.44 | 12.25 | 13.05 | 13.85 | 14.65 | 16.26 | 17.85 |

| 180 | 11.54 | 11.92 | 12.31 | 12.70 | 13.09 | 14.05 | 15.03 | 16.00 | 16.97 | 17.93 | 18.90 | 20.84 | 22.78 |

| 200 | 14.56 | 15.07 | 15.49 | 15.92 | 16.34 | 17.41 | 18.47 | 19.54 | 20.60 | 21.67 | 22.82 | 24.85 | 26.99 |

(Unit: kg)

With auto switch

| Tube Inner Diameter (mm) | Cylinder stroke (mm) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 175 | 200 | 250 | 300 | |

| 125 | 5.30 | 5.54 | 5.77 | 6.01 | 6.24 | 6.83 | 7.40 | 7.99 | 8.58 | 9.16 | 9.75 | 10.92 | 12.09 |

| 140 | 6.26 | 6.51 | 6.78 | 7.05 | 7.32 | 7.97 | 8.64 | 9.30 | 9.97 | 10.63 | 11.30 | 12.62 | 13.95 |

| 160 | 8.65 | 8.96 | 9.28 | 9.60 | 9.92 | 10.72 | 11.52 | 12.33 | 13.13 | 13.93 | 14.73 | 16.34 | 17.93 |

| 180 | 11.62 | 12.00 | 12.39 | 12.78 | 13.17 | 14.13 | 15.11 | 16.08 | 17.05 | 18.01 | 18.98 | 20.92 | 22.86 |

| 200 | 14.64 | 15.15 | 15.57 | 16.00 | 16.42 | 17.49 | 18.55 | 19.62 | 20.68 | 21.75 | 22.90 | 24.93 | 27.07 |

(Unit: kg)

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Block shape |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | Support bracket | Standard (common to through holes and taps on both ends) |

| Type | Pneumatic type |

CDQ2B125-10DCZ

CDQ2B125-50DCMZ

CDQ2B125-50DCZ

CQ2B160-40DCZ