Compact Cylinder, Guide-Rod Type CQM Series – Xi Lanh Khí Nén SMC

Product Description

Compact Cylinder, Guide Rod Type CQM Series to which a load can be directly mounted.

[Features]

· Mounting dimensions compatible with CQS and CQ2 series.

· Auto switch can be mounted/removed even when the plate is retracted.

Download

Compact Cylinder, Guide-Rod Type CQM Series Specifications – Xi Lanh Khí Nén SMC

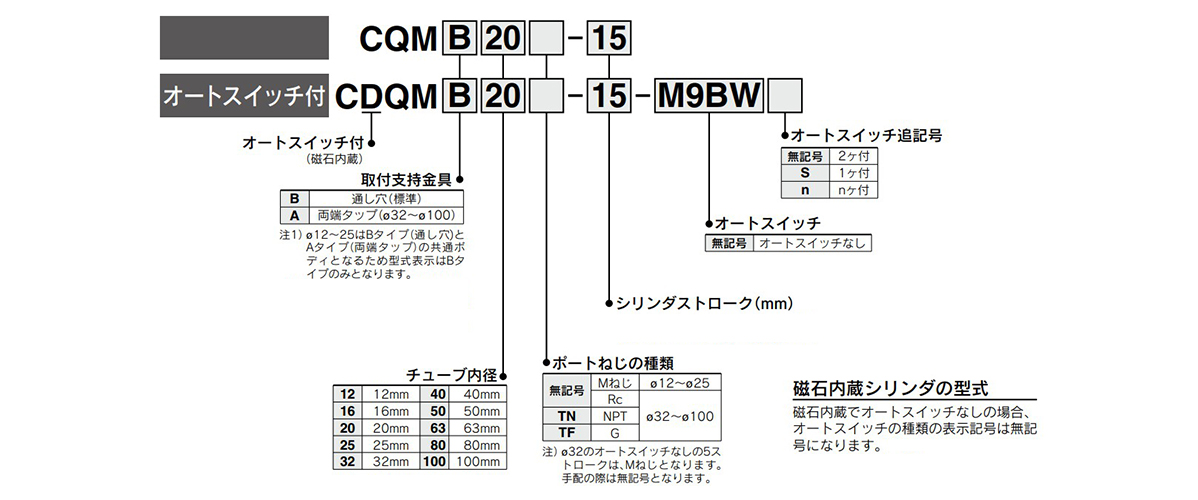

Model Number Notation

Model Number Notation

Specifications

| Tube Internal Diameter (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Pneumatic (non-lube) type | |||||||||

| Operating method | Double acting, single rod | |||||||||

| Applicable fluids | Air | |||||||||

| Proof pressure | 1.5 MPa | |||||||||

| Maximum operating pressure | 1.0 MPa | |||||||||

| Minimum operating pressure | 0.12 MPa | 0.1 MPa | ||||||||

| Ambient and working fluid temperature | Without auto switch: -10°C to +70°C (No freezing) With auto switch: -10°C to +60°C (No freezing) |

|||||||||

| Cushioning | Rubber bumper at both ends | |||||||||

| Stroke length tolerance | +1.0 mm* 0 |

|||||||||

| Mounting | Through hole | |||||||||

| Operating piston speed | 50 to 500 mm/s | 50 to 300 mm/s | ||||||||

- *Stroke length tolerance does not include the amount of bumper change.

Standard stroke

| Tube Internal Diameter (mm) | Standard stroke (mm) |

|---|---|

| 12, 16 | 5, 10, 15, 20, 25, 30 |

| 20, 25 | 5, 10, 15, 20, 25, 30, 35, 40, 45, 50 |

| 32, 40 | 5, 10, 15, 20, 25, 30, 35, 40, 45, 50, 75, 100 |

| 50, 63, 80, 100 | 10, 15, 20, 25, 30, 35, 40, 45, 50, 75, 100 |

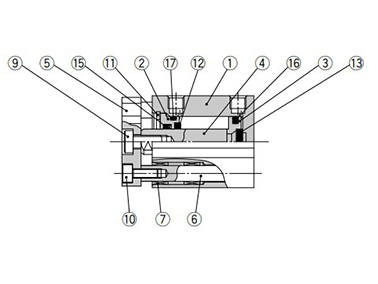

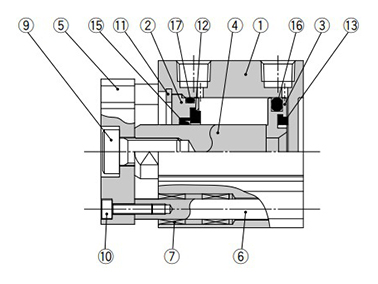

Structural drawing

ø12 to ø25 (12‑ to 25‑mm bore size)

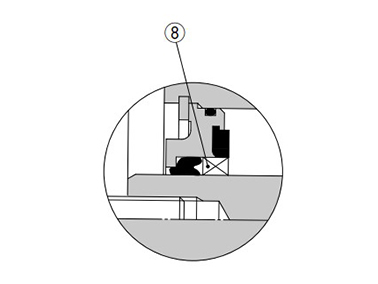

ø32 to ø100 (32‑mm to 100‑mm bore size)

ø50 to ø100 (50‑mm to 100‑mm bore size)

Component Parts

| Number | Description | Material | Note |

|---|---|---|---|

| 1 | Cylinder tube | Aluminum Alloy | Hard Anodize |

| 2 | Collar | Aluminum Alloy | ø12 to ø40 (12‑mm to 40‑mm bore size) Anodized |

| Aluminum alloy casting | ø50 to ø100 (50‑mm to 100‑mm bore size) Chromate, coated | ||

| 3 | Piston | Aluminum Alloy | – |

| 4 | Piston rod | Stainless steel | ø12 to ø25 (12‑mm to 25‑mm bore size) |

| Carbon steel | ø32 to ø100 (32‑mm to 100‑mm bore size) Hard chrome plated | ||

| 5 | Plate | Aluminum Alloy | Anodized |

| 6 | Guide rod | Stainless steel | – |

| 7 | Bushing | Resin/Copper alloy (Multiple layers) | – |

| 8 | Bushing | Resin/Copper alloy (Multiple layers) | ø50 to ø100 (50‑mm to 100‑mm bore size) |

| 9 | Hexagon socket head bolt | Carbon steel | Zinc chromate |

| 10 | Hexagon socket head bolt | Carbon steel | Zinc chromate |

| 11 | Retaining Ring | Carbon tool steel | Phosphate coated |

| 12 | Bumper A | Urethane | – |

| 13 | Damper B | Urethane | – |

| 14 | Magnet | – | – |

| 15 | Rod Gasket | NBR | – |

| 16 | Piston Gasket | NBR | – |

| 17 | Gasket | NBR | – |

Compact Cylinder, Guide-Rod Type CQM Series Example Dimensions

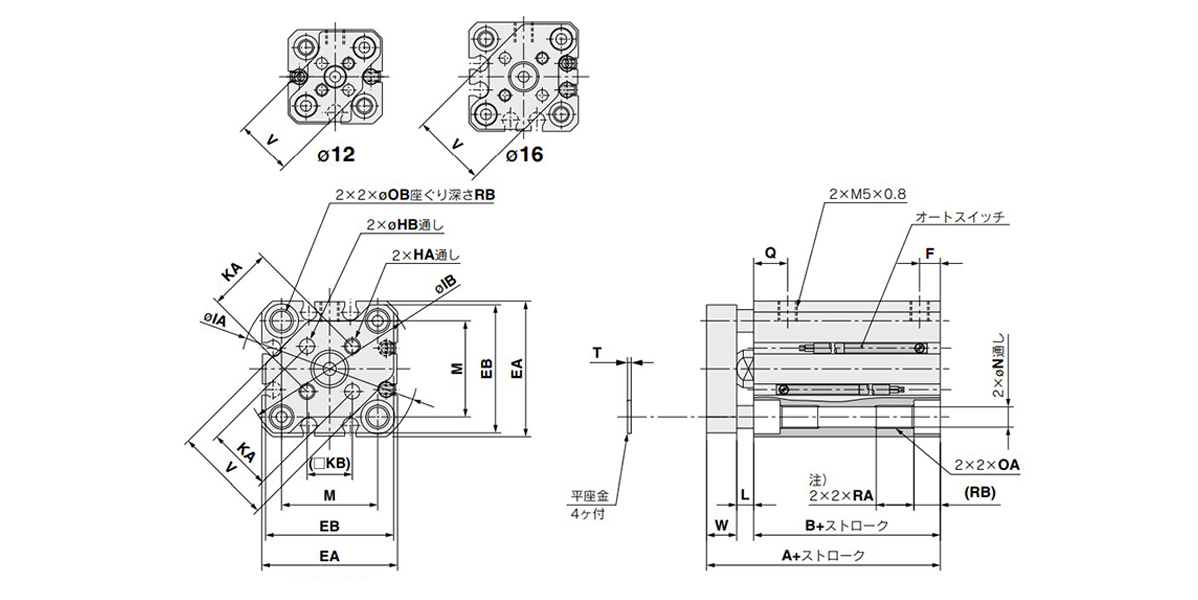

ø12 to ø25 (12‑ to 25‑mm bore size) dimensional drawing

(Unit: mm)

| Bore size (mm) |

Stroke range (mm) |

Without auto switch | With auto switch | EA | EB | F | HA | OA | HB | IA | IB | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | A | B | ||||||||||

| 12 | 5 to 30 | 26.5 | 17 | 31.5 | 22 | 25 | 24 | 5 | M3 × 0.5 | M4 × 0.7 | 3 (0 to +0.2) | 32 | 31.5 |

| 16 | 5 to 30 | 26.5 | 17 | 31.5 | 22 | 29 | 28 | 5 | M3 × 0.5 | M4 × 0.7 | 3 (0 to +0.2) | 38 | 37 |

| 20 | 5 to 50 | 32 | 19.5 | 42 | 29.5 | 36 | 34 | 5.5 | M4 × 0.7 | M6 × 1.0 | 4 (0 to +0.2) | 47 | 45.5 |

| 25 | 5 to 50 | 35.5 | 22.5 | 45.5 | 32.5 | 40 | 38 | 5.5 | M5 × 0.8 | M6 × 1.0 | 5 (0 to +0.2) | 52 | 50.5 |

(Unit: mm)

| Bore size (mm) |

KA | KB | L | M | N | OB | Q | RA | RB | T | V | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 10 ± 0.1 | 7.1 | 3.5 | 15.5 | 3.5 | 6.5 | 7.5 | 7 | 4 | 0.5 | 14.9 | 6 |

| 16 | 14 ± 0.1 | 9.9 | 3.5 | 20 | 3.5 | 6.5 | 7.5 | 7 | 4 | 0.5 | 20 | 6 |

| 20 | 17 ± 0.1 | 12 | 4.5 | 25.5 | 5.4 | 9 | 9 | 10 | 7 | 1 | 26 | 8 |

| 25 | 22 ± 0.1 | 15.6 | 5 | 28 | 5.4 | 9 | 11 | 10 | 7 | 1 | 30 | 8 |

Note) For the following bore/stroke sizes, the through-hole is threaded: Standard without auto switch: ø12 (12‑mm bore size) and ø16 (16‑mm bore size) 5 stroke; ø20 (20‑mm bore size) 5 to 15 stroke; ø25 (25‑mm bore size) 5 and 10 stroke. Built-in magnet with auto switch: ø20 (20‑mm bore size) 5 stroke.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Single Rods | Main Body Shape | Plate Cylinder |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | Cushion | Rubber bumper at both ends |

CDQMB12-2

CDQMB12-3

CDQMB12-4

CDQMB12-5

CDQMB12-5-A90VS

CDQMB12-5-A93VLS

CDQMB12-5-A93VS

CDQMB12-5-A96VLS

CDQMB12-5-M9BV

CDQMB16-1

CDQMB16-2

CDQMB16-3

CDQMB16-4

CDQMB16-5

CDQMB16-5-A93VLS

CDQMB16-5-A93VS

CDQMB16-5-M9BV

CDQMB16-5-M9BV3

CDQMB20-1

CDQMB20-2

CDQMB20-3

CDQMB20-4

CDQMB20-5

CDQMB20-5-A93VLS

CDQMB20-5-A93VS

CDQMB20-5-A96VS

CDQMB25-2

CDQMB25-3

CDQMB25-4

CDQMB25-5

CDQMB25-5-A90VLS

CDQMB25-5-A93M

CDQMB25-5-A93VLS

CDQMA32-1

CDQMA32-2

CDQMA32-3

CDQMA32-4

CDQMA32-5

CDQMA32-5-A93VLS

CDQMA32-5-A93VS

CDQMA32-5-A93VZS

CDQMA40-5

CDQMA40-5-A93VLS

CDQMA40-5-M9BV

CDQMA40-5-M9BVL

CDQMA40-5-M9BVLS

CDQMA40-5-M9BVS

CDQMA40-5-M9BVZ

CDQMA40-5-M9NV

CDQMA40-5-M9NVL

CDQMA50-5-M9PV

CDQMA50-10

CDQMA50-10-A73L

CDQMA50-10-A93

CDQMA50-10-A93L

CDQMA63-5

CDQMA63-10

CDQMA63-10-A73Z

CDQMA63-10-A93

CDQMA63-10-A93L

CDQMA63-10-A93VL

CDQMA63-10-A93Z

CDQMA80-10

CDQMA80-10-A93

CDQMA80-10-A93V

CDQMA80-10-A93VL

CDQMA80-10-A93VS

CDQMA80-10-M9B

CDQMA80-10-M9BL

CDQMA100-10

CDQMA100-10-A93VS

CDQMA100-10-A93Z

CDQMA100-10-M9B

CDQMA100-10-M9BVL

CDQMA100-10-M9BVZS

CDQMA100-10-M9BWVS

CDQMA100-10-M9NVL

CDQMB12-5-A90VS

CDQMB16-5-A93VLS

CDQMB20-5-A93VLS

CDQMB25-5-A90VLS

CDQMA32-5-A93VLS

CDQMA40-5-A93VLS

CDQMA50-10-A73L

CDQMA63-10-A73Z

CDQMA80-10-A93VL

CDQMA100-10-A93VS