Bộ lọc khí SMC Air Filter SFA100/200/300 Series SFA101 SFA102 SFA103 SFA200 SFA201 SFA202 SFA203 SFA300

Clean Gas Filter Cartridge Type Disc, SFA100/200/300 Series

Clean gas filter that can be used in a wide range of environments.

Download

Bộ lọc khí SMC Air Filter SFA100/200/300 Series SFA101 SFA102 SFA103 SFA200 SFA201 SFA202 SFA203 SFA300

Clean Gas Filter: Cartridge Type / Disc Type, SFA100/SFA200/SFA300 Series Specifications – Bộ lọc khí SMC

[Features] ·Precision filtration of compressed air and nitrogen·Consistent cleaning, assembly, testing, and antistatic sealed double packaging of all parts in a clean environment

·Cartridge of PTFE membrane element (filtration degree 0.01 µm (filtration efficiency 99.99%))

·Element exchange is possible

·Cartridge type / disc type

SFA103 external appearance

SFA200 external appearance

SFA302 external appearance

| Applicable Fluid | Air, nitrogen | |

|---|---|---|

| Operating Pressure*1 | MAX. 0.99 MPa, Vacuum 1.3 × 10-6 kPa | |

| Operating Temperature | 5 to 80℃ | |

| Element Proof Differential Pressure | MAX. 0.1 MPa | |

| Element Reverse Differential Pressure | MAX. 0.05 MPa | |

| Filtration*2 | 0.01 μm (filtration efficiency 99.99%) | |

| Main Material | Case | SUS316 (Interior/Exterior: Electrolytic polishing) |

| Filtration Medium | PTFE membrane | |

| Seal | Fluoroelastomer (FKM) | |

| Packaging | Antistatic sealed double package | |

*1: The maximum operating pressure is 0.99 MPa since this product does not conform to the High Pressure Gas Safety Law (Japan). Ensure that, if 0.1 MPa is exceeded, there is no pressure fluctuation during use.

*2: Measured under manufacturer’s specified conditions.

Model

| Model | Rated Flow L/min (ANR)*1 | Connection | Filtration Area cm2 | Element Part No.*2 | Weight (kg) |

|---|---|---|---|---|---|

| SFA100-02 | 26 | Rc 1/4 (female thread) | 13.85 | ED001S-X10V | 0.34 |

| SFA101-02 | NPT 1/4 (female thread) | ||||

| SFA200-02 | 70 | Rc 1/4 (female thread) | 33.18 | ED101S-X10V | 0.44 |

| SFA201-02 | NPT 1/4 (female thread) | ||||

| SFA300-02 | 140 | Rc 1/4 (female thread) | 56.75 | ED201S-X10V | 0.66 |

| SFA301-02 | NPT 1/4 (female thread) | ||||

| SFA102-02 | 26 | TSJ 1/4 Tube, Swage Joint |

13.85 | ED001S-X10V | 0.38 |

| SFA202-02 | 70 | 33.18 | ED101S-X10V | 0.49 | |

| SFA302-02 | 140 | 56.75 | ED201S-X10V | 0.70 | |

| SFA103-02 | 26 | UOJ1/4 Union O-Ring, Joint |

13.85 | ED001S-X10V | 0.42 |

| SFA203-02 | 70 | 33.18 | ED101S-X10V | 0.53 | |

| SFA303-02 | 140 | 56.75 | ED201S-X10V | 0.75 |

*1: At inlet pressure of 0.7 MPa and pressure drop of 0.02 MPa.

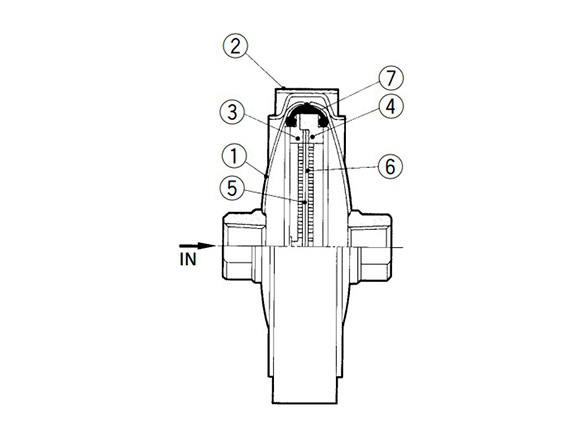

*2: Contents of diagram numbers (3) to (7) are included in the element part no. (refer to diagrams).

Product Diagram

Cartridge Type / Disc Type, SFA100/SFA200/SFA300 Series diagram

| Number | Part name | Material | Note |

|---|---|---|---|

| 1 | Case | SUS 316 | Electrolytic polishing (interior/exterior) |

| 2 | V Clamp | SUS304 | – |

| 3 | Holder 1 | Polyester | Element |

| 4 | Holder 2 | ||

| 5 | Filtration Medium | PTFE | |

| 6 | Packing | FKM | |

| 7 | V packing |

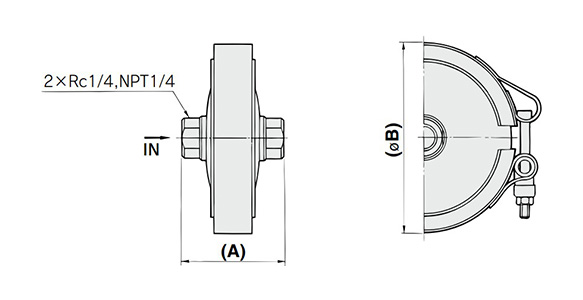

Product Outline Dimensional Drawing

SFA100-02/SFA101-02/SFA200-02/SFA201-02/SFA300-02/SFA301-02 dimensional drawings

(Unit: mm)

| Model | Connection | (A) | (øB) |

|---|---|---|---|

| SFA100-02 | Rc 1/4 | 46 | 76 |

| SFA101-02 | NPT 1/4 | ||

| SFA200-02 | Rc 1/4 | 51 | 96 |

| SFA201-02 | NPT 1/4 | ||

| SFA300-02 | Rc 1/4 | 59 | 120 |

| SFA301-02 | NPT 1/4 |

(): Reference dimensions

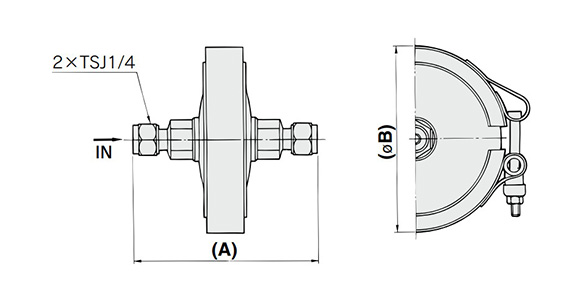

SFA102-02/SFA202-02/SFA302-02 dimensional drawings

(Unit: mm)

| Model | Connection | (A) | (øB) |

|---|---|---|---|

| SFA102-02 | TSJ 1/4 (Tube Swage Joint) | 89 | 76 |

| SFA202-02 | 93 | 96 | |

| SFA302-02 | 101 | 120 |

(): Reference dimensions

(Unit: mm)

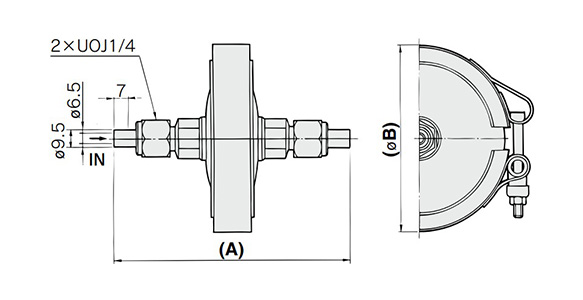

SFA103-02/SFA203-02/SFA303-02 dimensional drawing

(Unit: mm)

| Model | Connection | (A) | (øB) |

|---|---|---|---|

| SFA103-02 | UOJ 1/4 (Union O-Ring Joint) | 117 | 76 |

| SFA203-02 | 122 | 96 | |

| SFA303-02 | 130 | 120 |

(): Reference dimensions

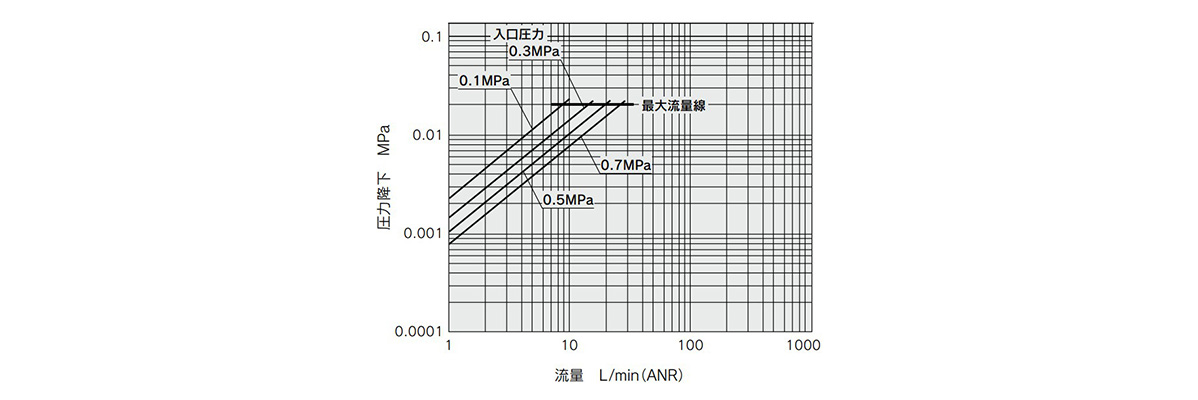

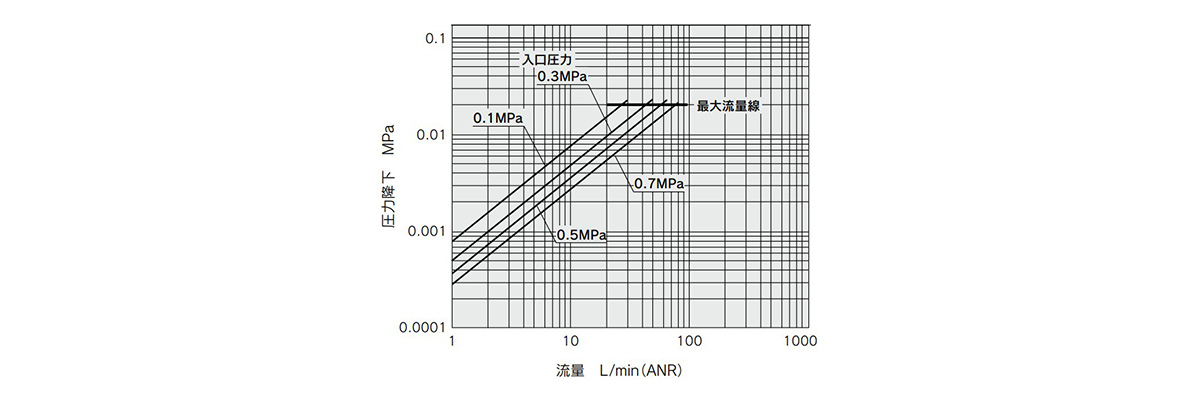

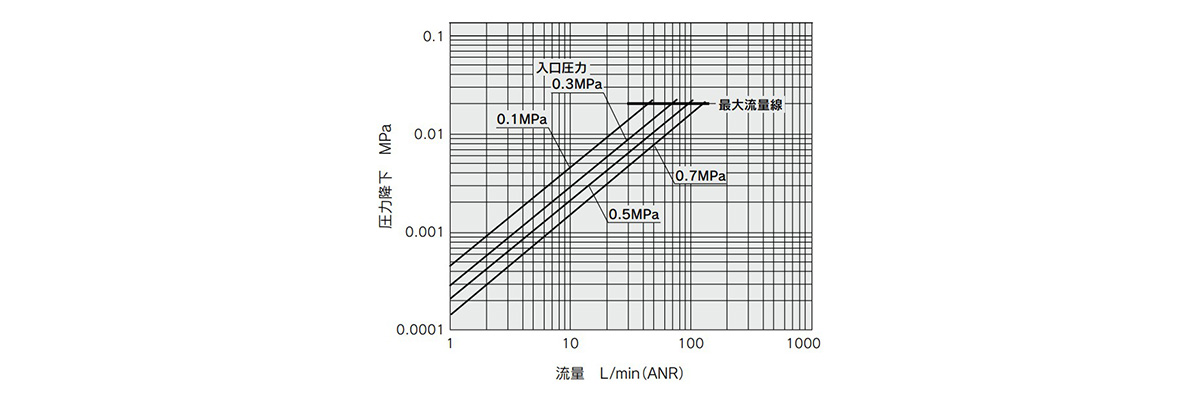

Product Flow Rate Characteristics (Fluid: Compressed Air / Inlet Temperature: 20°C)

SFA10□ flow rate characteristics

SFA20□ flow rate characteristics

SFA30□ flow rate characteristics

Precautions

- *Ensure that you read the specific product precautions prior to use.

- *Confirm the specifications. The Clean Gas Filter is designed for use with compressed air and nitrogen gas only. Do not use with fluids (gases) other than those stated in the specifications, and do not exceed the specified ranges for pressure or temperature, as this will cause damage, etc.

- *Select a product according to the maximum consumption flow rate. When using compressed air for air blow applications, etc., calculate the maximum volume of air that will be consumed before selecting the SF□ series product size. (Using a product that exceeds the maximum air flow and running excessive compressed air can cause the cleanliness of the compressed air to deteriorate and/or damage the element.)

- *Set the processing flow rate with an initial pressure drop of 0.02 MPa or less. If the initial pressure drop is set too high, the service life will be shorter due to clogging.

- *See the manufacturer’s catalog for product information other than the above.

- *Product pictures are example representations for the product series. Please be aware that actual product specifications may be different.

ED101S-X10V

ED201S-X10V

SFA100-02

SFA101-02

SFA103-02

SFA200-02

SFA201-02

SFA202-02

SFA300-02

SFA301-02

SFA302-02

SFA303-02

SFA100 SFA101 SFA102 SFA103 SFA200 SFA201 SFA202 SFA203 SFA300 SFA301 SFA302 SFA303 ED001S ED101S ED201S

Giới thiệu SMC Việt Nam

SMC là thương hiệu hàng đầu thế giới trong lĩnh vực công nghệ khí nén, cung cấp các giải pháp tiên tiến nhằm hỗ trợ tự động hóa và tối ưu hóa quy trình sản xuất.

Với nền tảng vững chắc trong ngành, SMC Việt Nam luôn đi đầu trong việc nghiên cứu, đổi mới và phát triển sản phẩm, góp phần nâng cao năng suất và tiết kiệm lao động cho các doanh nghiệp công nghiệp.

Với phương châm “đóng góp vào tự động hóa và tiết kiệm lao động trong ngành công nghiệp”, SMC Việt Nam không ngừng cải tiến và mang đến những sản phẩm công nghệ tiên tiến nhất.

SMC Việt Nam cam kết cung cấp những giải pháp hiện đại, giúp khách hàng duy trì lợi thế cạnh tranh trên thị trường.

Medin Company cung cấp các sản phẩm SMC tại Việt Nam.

Đa dạng các sản phẩm và giải pháp khí nén phục vụ cho nhiều ngành công nghiệp khác nhau, bao gồm:

- Xy lanh khí nén – Giúp kiểm soát chuyển động chính xác và hiệu quả.

- Van điện từ – Ứng dụng rộng rãi trong điều khiển luồng khí nén.

- Bộ lọc khí nén – Đảm bảo chất lượng khí nén tối ưu.

- Cảm biến và bộ điều khiển – Tăng cường tự động hóa trong quy trình sản xuất.

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.