Air Slide Table, Height Interchangeable Type, MXQ Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

An air slide table with improved auto switch visibility.

[Features]

· Improved allowable kinetic energy.

· The table shape was designed in consideration of functionality and maintenance.

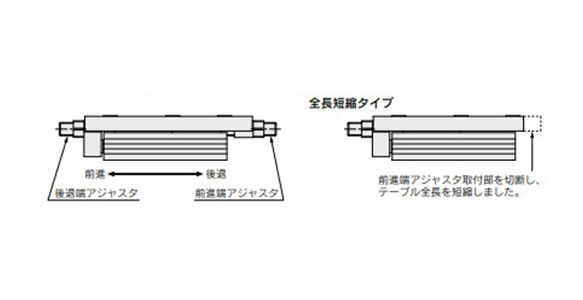

· Shorter length table available.

Download

Air Slide Table, Height Interchangeable Type Specifications – Xi Lanh Khí Nén SMC

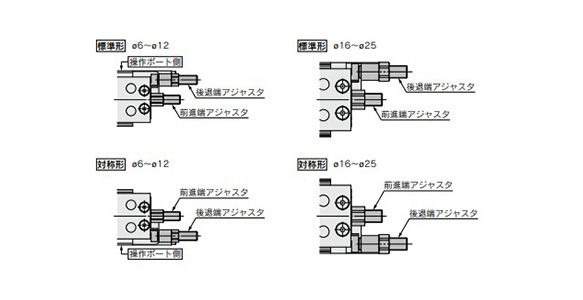

Adjuster Mounting Position (Excluding Centralized Adjuster)

Image of adjuster mounting positions

Centralized Adjuster Mounting Position

Image of centralized adjuster mounting positions

Specifications

| Cylinder Inner Diameter (mm) | 6 | 8 | 12 | 16 | 20 | 25 |

|---|---|---|---|---|---|---|

| Piping connection port diameter | M5 × 0.8 | |||||

| Fluid | Air | |||||

| Action | Double-acting type | |||||

| Operating Pressure | 0.15 to 0.7 MPa *1 (End lock: 0.35 to 0.7 MPa) | |||||

| Guaranteed Proof Pressure | 1.05 MPa | |||||

| Ambient Temperature and Operating Fluid Temperature | -10 to 60°C | |||||

| Operating Speed Range (Average Operating Speed) | 50 to 500 mm/s (Metal stopper with bumper: 50 to 300 mm/s) (Metal stopper: 50 to 200 mm/s) In the standard stroke table on p. 83, * is 50 to 300 mm/s |

|||||

| Cushioning (without Stroke Adjuster) | Internal rubber cushioning | |||||

| Cushioning (with Stroke Adjuster) | Metal stopper with bumper, rubber stopper Shock absorber, metal stopper |

|||||

| Lubrication | Not required | |||||

| Auto Switch | Solid-state auto switch, reed type auto switch (2-wire type, 3-wire type) 2-color indicator solid state auto switch (2-wire type, 3-wire type) |

|||||

| Stroke Length Tolerance | 0 to +2 mm | |||||

*1:

Using at less than the minimum operating pressure will lower the repeatability accuracy.

Minimum operating pressure for metal stopper with bumper: Pressure required to fully compress the protrusion of the bumper until is contacts the metal portion.

For the ø20 inner diameter cylinder with shock absorber, the operating pressure is 0.15 to 0.6 MPa.

Theoretical Output

Using dual rods provides double the output of conventional cylinders.

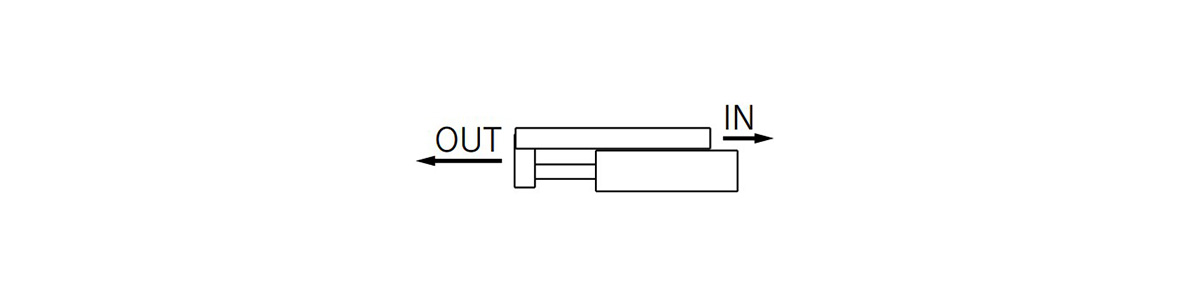

Drawing (OUT, IN)

| Cylinder Internal Diameter (mm) | Rod Diameter (mm) | Operating Direction | Piston Area (mm2) | Operating Pressure (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | ||||

| 6 | 3 | OUT | 57 | 11 | 17 | 23 | 29 | 34 | 40 |

| IN | 42 | 8 | 13 | 17 | 21 | 25 | 29 | ||

| 8 | 4 | OUT | 101 | 20 | 30 | 40 | 51 | 61 | 71 |

| IN | 75 | 15 | 23 | 30 | 38 | 45 | 53 | ||

| 12 | 6 | OUT | 226 | 45 | 68 | 90 | 113 | 136 | 158 |

| IN | 170 | 34 | 51 | 68 | 85 | 102 | 119 | ||

| 16 | 6 | OUT | 402 | 80 | 121 | 161 | 201 | 241 | 281 |

| IN | 346 | 69 | 104 | 138 | 173 | 207 | 242 | ||

| 20 | 8 | OUT | 628 | 126 | 188 | 251 | 314 | 377 | 440 |

| IN | 528 | 106 | 158 | 211 | 264 | 317 | 369 | ||

| 25 | 10 | OUT | 982 | 196 | 295 | 393 | 491 | 589 | 687 |

| IN | 825 | 165 | 247 | 330 | 412 | 495 | 577 | ||

Precautions

When using a metal stopper with a bumper for positioning, the theoretical output differs by the force required to fully compress the bumper

Maximum Load Weight

| Model | Without Adjuster | Adjuster Options | ||||

|---|---|---|---|---|---|---|

| Internal Rubber Cushioning |

Rubber Stopper |

Metal stopper with Bumper |

Shock Absorber / RJ | Metal Stopper |

||

| Horizontal | Vertical | |||||

| MXQ6 | 0.6 | 0.6 | – | 0.6 | 0.6 | |

| MXQ8 | 1 | 1 | 1 | 1 | 1 | |

| MXQ12 | 2 | 2 | 2 | 1.5 | 1 | 2 |

| MXQ16 | 4 | 4 | 4 | 4 | 2.5 | 4 |

| MXQ20 | 6 | 6 | 6 | 6 | 6 | |

| MXQ25 | 9 | 9 | 9 | 9 | 6 | 9 |

(Increment: kg)

Basic Information

| Type | L-Shaped Table Type | Table Material | Aluminum | Guide Type | Linear guide type |

|---|---|---|---|---|---|

| Environment | General Purpose |

MXQ6-10Z[1,2,3,4,5] MXQ6-10ZD

MXQ6-10ZD[3,6] MXQ6-10ZE

MXQ6-10ZE[1,2,3,4,5] MXQ6-10ZEJ

MXQ6-10ZEJ[3,6,8] MXQ6-10ZEM

MXQ6-10ZEM[3,6,8] MXQ6-10ZF

MXQ6-10ZF[3,6,8] MXQ6-10ZG

MXQ6-10ZG[3,6] MXQ6-10ZH

MXQ6-10ZH[2,3] MXQ8-10Z

MXQ8-10Z[1,2,3,4,5] MXQ8-10ZA

MXQ8-10ZA[3,6] MXQ8-10ZB

MXQ8-10ZB[2,3] MXQ8-10ZBF

MXQ8-10ZBF[3,6] MXQ8-10ZBJ

MXQ8-10ZBJ[3,6] MXQ8-10ZBM

MXQ8-10ZBM[3,6] MXQ8-10ZC

MXQ8-10ZC[3,6,8]

MXQ12-10Z[1,2,3,4,5] MXQ12-10ZA

MXQ12-10ZA[3,6] MXQ12-10ZB

MXQ12-10ZB[2,3] MXQ12-10ZBF

MXQ12-10ZBF[3,6] MXQ12-10ZBJ

MXQ12-10ZBJ[3,6] MXQ12-10ZBM

MXQ12-10ZBM[3,6] MXQ16-10Z

MXQ16-10Z[1,2,3,4,5] MXQ16-10ZA

MXQ16-10ZA[3,6] MXQ16-10ZB

MXQ16-10ZB[2,3] MXQ16-10ZBF

MXQ16-10ZBF[3,6] MXQ16-10ZBJ

MXQ16-10ZBJ[3,6] MXQ16-10ZBM

MXQ16-10ZBM[3,6] MXQ16-10ZC

MXQ16-10ZC[3,6,8]

MXQ20-10Z[1,2,3,4,5] MXQ20-10ZA

MXQ20-10ZA[3,6] MXQ20-10ZB

MXQ20-10ZB[2,3] MXQ20-10ZBF

MXQ20-10ZBF[3,6] MXQ20-10ZBJ

MXQ20-10ZBJ[3,6] MXQ20-10ZBM

MXQ20-10ZBM[3,6] MXQ20-10ZC

MXQ20-10ZC[3,6,8] MXQ20-10ZD

MXQ20-10ZD[3,6,8] MXQ20-10ZE

MXQ20-10ZE[1,2,3,4,5] MXQ20-10ZEC

MXQ20-10ZEC[3,6,8] MXQ20-10ZEJ

MXQ20-10ZEJ[3,6,8] MXQ20-10ZEM

MXQ20-10ZEM[3,6,8] MXQ20-10ZF

MXQ25-10Z[1,2,3,4,5] MXQ25-10ZA

MXQ25-10ZA[3,6] MXQ25-10ZB

MXQ25-10ZB[2,3] MXQ25-10ZBF

MXQ25-10ZBF[3,6] MXQ25-10ZBJ

MXQ25-10ZBJ[3,6] MXQ25-10ZBM

MXQ25-10ZBM[3,6] MXQ25-10ZC

MXQ25-10ZC[3,6,8] MXQ25-10ZD

MXQ25-10ZD[3,6,8] MXQ25-10ZE

MXQ25-10ZE[1,2,3,4,5] MXQ25-10ZEC

MXQ25-10ZEC[3,6,8] MXQ25-10ZEJ

MXQ25-10ZEJ[3,6,8] MXQ25-10ZEM

MXQ25-10ZEM[3,6,8] MXQ25-10ZF

MXQ25-10ZF[3,6,8]