Air Cylinder, Standard Type, Double Acting, Single Rod CA2 Series – Xi Lanh Khí Nén SMC

Product Description

– Xi Lanh Khí Nén SMC

An air cylinder with easy air cushion control.

[Features]

· Weight reduced by up to 15%.

· Various switches such as compact auto switches and strong magnetic field resistant switches can be mounted.

· Part numbers are set for products with rod-end brackets and pivot brackets. (No need to order separately.)

*See catalog for specification details.

Download

Air Cylinder, Standard Type, Double Acting, Single Rod CA2 Series Specifications – Xi Lanh Khí Nén SMC

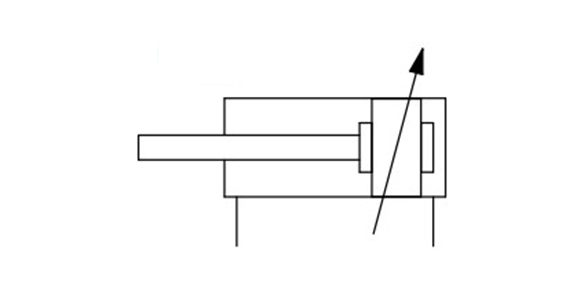

Air Cylinder, Standard Type, Double Acting, Single Rod CA2 Series external appearance

Symbol Double acting Air cushion

Specifications

| Tube Internal Diameter (mm) | 40 | 50 | 63 | 80 | 100 | ||

|---|---|---|---|---|---|---|---|

| Applicable fluids | Air | ||||||

| Operating method | Double acting | ||||||

| Proof pressure | 1.5 MPa | ||||||

| Maximum operating pressure | 1.0 MPa | ||||||

| Ambient temperature and working fluid temperature | Without auto switch: -10°C to 70°C*1 With auto switch: -10°C to 60°C*1 |

||||||

| Minimum operating pressure | 0.05 MPa | ||||||

| Operating piston speed | 50 to 500 mm/s | ||||||

| Cushioning | Air cushion or rubber bumper | ||||||

| Stroke length tolerance | Up to 250st: (0 to +1.0) 251 to 1,000st: (0 to +1.4) 1,001 to 1,500st: (0 to +1.8) 1,501 to 1,800st: (0 to +2.2) | ||||||

| Lubrication | Not required (non-lube) | ||||||

| Mounting style | Basic type, foot type, rod-end flange type, head-end flange type single clevis type, double clevis type, center trunnion type |

||||||

| Allowable kinetic energy (J)*2 |

Air cushion | When activated | 2.8 | 4.6 | 7.8 | 16 | 29 |

| When not activated | 0.33 | 0.56 | 0.91 | 1.5 | 2.68 | ||

| Rubber cushion | 1.8 | 3.6 | 6.0 | 12.0 | 12.0 | ||

- *1No freezing.

- *2Activate the air cushion when operating the cylinder. If this is not done, the piston rod assembly or the tie-rods will be damaged if the allowable kinetic energy exceeds the values shown in the above table.

Standard Strokes

| Bore size |

Standard strokeNote 1) | Max. manufacturable stroke |

|

|---|---|---|---|

| Stroke range (1) | Stroke range (2) | ||

| 40 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500 | Up to 1,800 | Up to 2,700 |

| 50, 63 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600 | ||

| 80, 100 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 700 | ||

Note 1) Intermediate strokes not listed above are produced to order.

Note 2) Applicable strokes should be confirmed according to the usage. For details, please refer to “Air Cylinder Model Selection” in the manufacturer’s catalog. In addition, products that exceed stroke range 1 may not be able to fulfill the specifications due to deflection, etc.

Note 3) Please consult with the manufacturer for manufacturability and the part numbers when exceeding the stroke range 2.

Note 4) The stroke range with rod boot is 20 to 1,800 mm. Please consult with the manufacturer support center when exceeding 1,800 mm strokes.

CA2B40-5Z

CA2B40-8Z

CA2B40-10Z

CA2B40-12Z

CA2B40-13Z

CA2B40-15Z

CA2B40-17Z

CA2B40-20JZ

CA2B40-20NZ

CA2B40-20Z

CA2B40-20Z-XC68

CA2B40-22JZ

CA2B40-25JZ

CA2B40-25KZ

CA2B40-25NZ

CA2B40-25NZ-XC4

CA2B40-25Z

CA2B40-25Z-XB6

CA2B40-25Z-XC4

CA2B40-27Z

CA2B40-28Z

CA2B40-30JZ

CA2B40-30NZ

CA2B40-30Z

CA2B40-30Z-W

CA2B50-5Z

CA2B50-10Z

CA2B50-15Z

CA2B50-18Z

CA2B50-20NZ

CA2B50-20Z

CA2B50-20Z-XB6

CA2B50-21NZ

CA2B50-25JZ

CA2B50-25KZ

CA2B50-25NZ

CA2B50-25Z

CA2B50-25Z-V

CA2B50-25Z-XB6

CA2B50-25Z-XC4

CA2B50-27Z

CA2B50-28Z

CA2B50-30JZ

CA2B50-30NZ

CA2B50-30Z

CA2B50-30Z-XB6

CA2B50-35JZ

CA2B50-35KZ

CA2B50-35Z

CA2B50-36Z

CA2B50-37Z

CA2B50-40JZ

CA2B50-40KZ

CA2B63-10Z

CA2B63-12Z

CA2B63-13Z

CA2B63-14Z

CA2B63-15Z

CA2B63-16Z

CA2B63-17Z

CA2B63-18Z

CA2B63-20JZ

CA2B63-20KZ

CA2B63-20NZ

CA2B63-20Z

CA2B63-22Z

CA2B63-23Z

CA2B63-24Z

CA2B63-25JZ

CA2B63-25JZ-XC4

CA2B63-25KZ

CA2B63-25NZ

CA2B63-25Z

CA2B63-25Z-XB6

CA2B63-25Z-XC4

CA2B63-30JZ

CA2B63-30KZ

CA2B63-30NZ

CA2B63-30Z

CA2B63-30Z-XC5

CA2B80-10Z

CA2B80-12Z

CA2B80-15Z

CA2B80-16Z

CA2B80-20JZ

CA2B80-20Z

CA2B80-24Z

CA2B80-25JZ

CA2B80-25KZ

CA2B80-25NZ

CA2B80-25Z

CA2B80-25Z-W

CA2B100-1Z

CA2B100-3Z

CA2B100-5Z

CA2B100-7Z

CA2B100-10Z

CA2B100-10Z-XB6

CA2B100-12Z

CA2B100-15Z

CA2B100-18Z

CA2B100-20JZ

CA2B100-20KZ

CA2B100-20NZ

CA2B100-20Z

CA2B100-24NZ

CA2B100-25JZ

CA2B100-25NZ