Xi Lanh Kẹp SMC LEHF Series LEHF10K2 LEHF20K2 LEHF32K2 LEHF40K2

Electric Gripper, 2-Finger Type, LEHF Series

Electric gripper for a variety of workpieces with a long stroke.

Download

Xi Lanh Kẹp SMC LEHF Series LEHF10K2 LEHF20K2 LEHF32K2 LEHF40K2

LEHF Series 2-Finger Type Electric Gripper Specifications – Xi Lanh Kẹp SMC

[Features] · Step motor (servo 24 V DC).· Easy to complete setup with 2 items, namely, position and thrust.

· Controllers are shipped with the setup for actuator specifications (the actuator and controller are sold as a package).

· With drop prevention function.

· Self-lock mechanism reduces power consumption.

· With gripping check function.

· Possible to set position, speed and force (64 points).

*Values inside parentheses () are for long stroke.

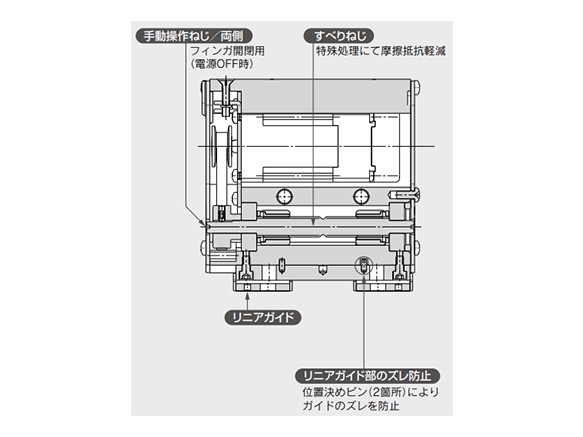

LEHF Series 2-Finger Type Electric Gripper external appearance

Features of LEHF Series 2-Finger Type Electric Gripper

Specifications

| Model | LEHF10 | LEHF20 | LEHF32 | LEHF40 | ||

|---|---|---|---|---|---|---|

| Actuator specifications | Open and close stroke / both sides (mm) | Basic | 16 | 24 | 32 | 40 |

| Long stroke | 32 | 48 | 64 | 80 | ||

| Lead (mm) | 40/15 (2.667) | 50/15 (3.333) | 70/16 (4.375) | 70/16 (4.375) | ||

| Gripping force (N)*1 *3 | 3 to 7 | 11 to 28 | 48 to 120 | 72 to 180 | ||

| Open and close speed / pushing speed (mm/s)*2 *3 | 5 to 80 / 5 to 20 | 5 to 100 / 5 to 30 | ||||

| Actuation type | Slide screw + belt | |||||

| Finger guide type | Linear guide (no circulation) | |||||

| Repeated length measurement accuracy (mm)*4 | ±0.05 | |||||

| Finger backlash / one side (mm)*5 | 0.5 or less | |||||

| Repeatability (mm)*6 | ±0.05 | |||||

| Positioning repeatability / one side (mm) | ±0.1 | |||||

| Lost motion / one side (mm)*7 | 0.3 or less | |||||

| Impact/vibration resistance (m/s2)*8 | 150/30 | |||||

| Max. operating frequency (C.P.M) | 60 | |||||

| Operating temp. range (°C) | 5 to 40 | |||||

| Operating humidity range (%RH) | 90 or less (no condensation) | |||||

| Weight (g) | Basic | 340 | 610 | 1,625 | 1,980 | |

| Long stroke | 370 | 750 | 1,970 | 2,500 | ||

| Electric specifications | Motor size | □20 | □28 | □42 | ||

| Motor type | Step motor (servo 24 V DC) | |||||

| Encoder | Incremental A/B phase (800 pulse/rotation) | |||||

| Rated voltage (V) | 24 V DC ±10% | |||||

| Power consumption / standby power consumption when operating (W)*9 | 11/7 | 28/15 | 34/13 | 36/13 | ||

| Max. instantaneous power consumption (W)*10 | 19 | 51 | 57 | 61 | ||

*1 Gripping force should be from 10 to 20 times the workpiece weight. Moving force should be 150% when releasing the workpiece. Gripping force accuracy should be: LEHF10: ±30% (F.S.), LEHF20: ±25% (F.S.), LEHF32/LEHF40: ±20% (F.S.). Gripping the workpiece with a heavy attachment and fast pushing speed may not satisfy the product specifications. In this case, decrease the weight and lower the pushing speed.

*2 Pushing speed should be set within the range during pushing (gripping) operation. Otherwise, it may cause malfunction. The open/close speed and pushing speed are for both fingers. The speed for one finger is 1/2 this value.

*3 The speed and force may change depending on the cable length, load, mounting conditions, etc. Furthermore, if the cable length exceeds 5 m, then the speed and force will decrease by up to 10% for each 5 m. (At 15 m: reduced by up to 20%)

*4 Repeated length measurement accuracy means dispersion (value on the controller monitor) when the workpiece is repeatedly held in the same position.

*5 There is no effect on the backlash during pushing (gripping). Make the stroke longer by the amount of backlash when opening.

*6 Repeatability means the variation of the gripping position (workpiece position) when the gripping operation is repeatedly performed in the same sequence for the same workpiece.

*7 A reference value for correcting an error in reciprocal operation which occurs during the positioning operation.

*8 Impact resistance: No malfunction occurred when the slide table was tested with a drop tester in both an axial direction and a perpendicular direction to the lead screw. (Test was performed with the gripper in the initial state.) Vibration resistance: No malfunction occurred in a test ranging from 45 to 2,000 Hz. Test was performed in both an axial direction and a perpendicular direction to the lead screw. (Test was performed with the actuator in the initial state.)

*9 The power consumption (including the controller) is for when the actuator is operating. The standby power consumption when operating is for when the gripper is stopped in the set position during operation (including energy-saving mode when gripping).

*10 The maximum instantaneous power consumption (including the controller) is for when the actuator is operating. This value can be used for the selection of the power supply.

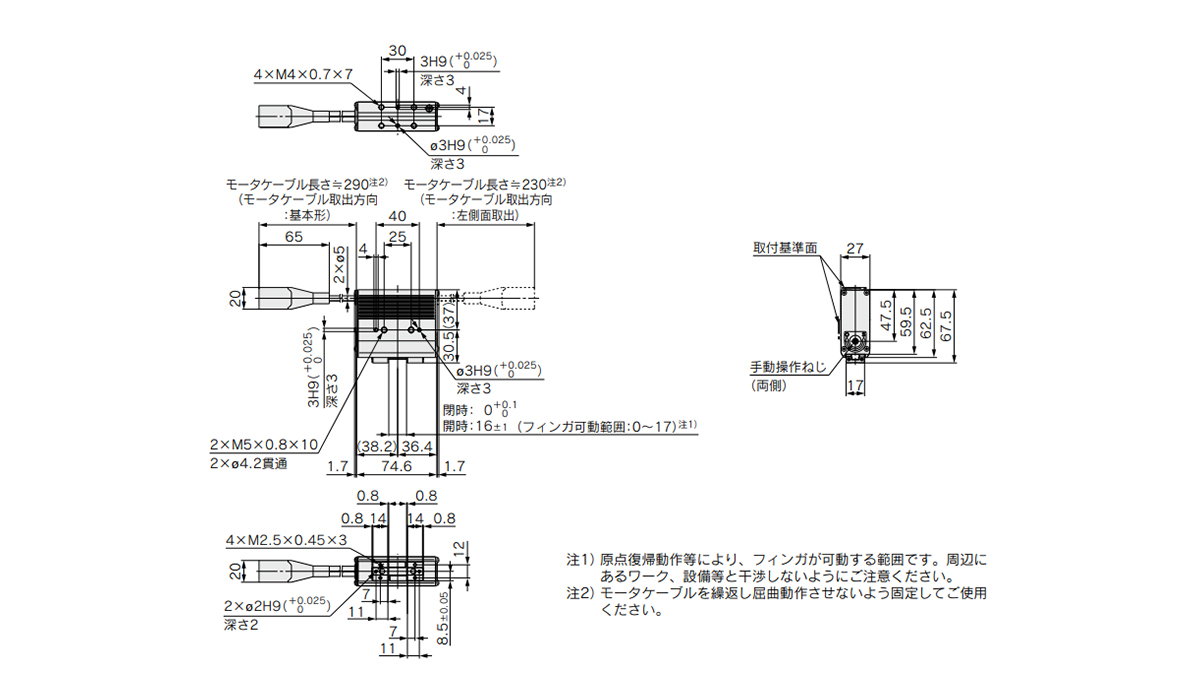

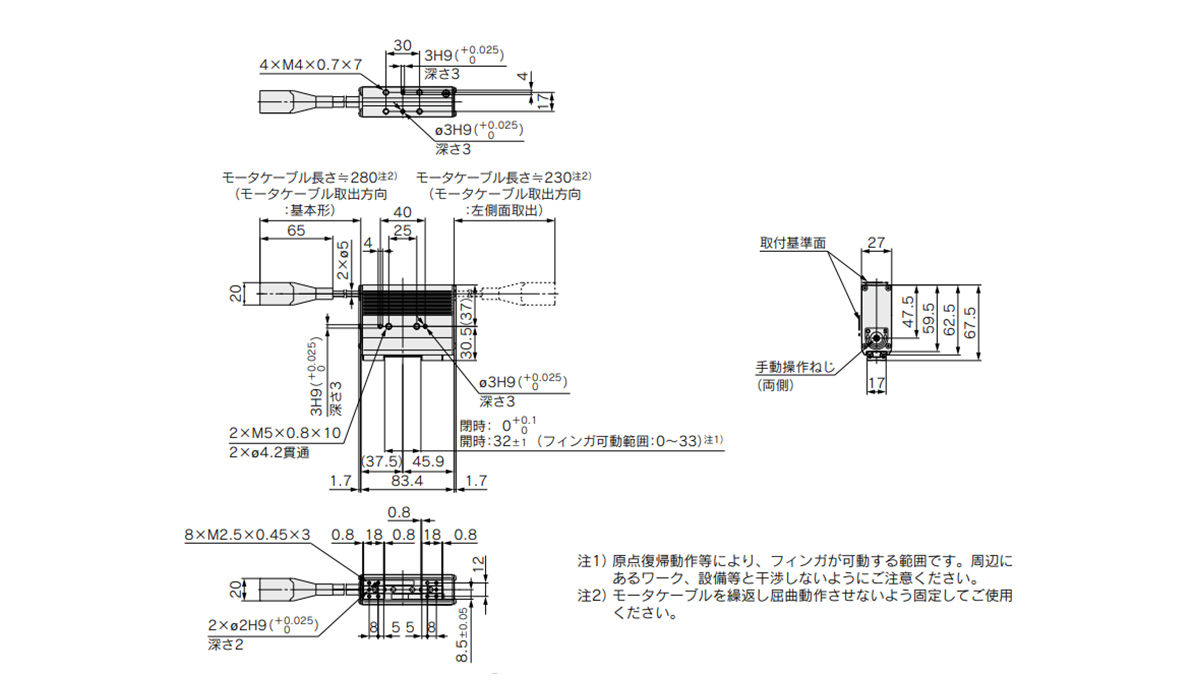

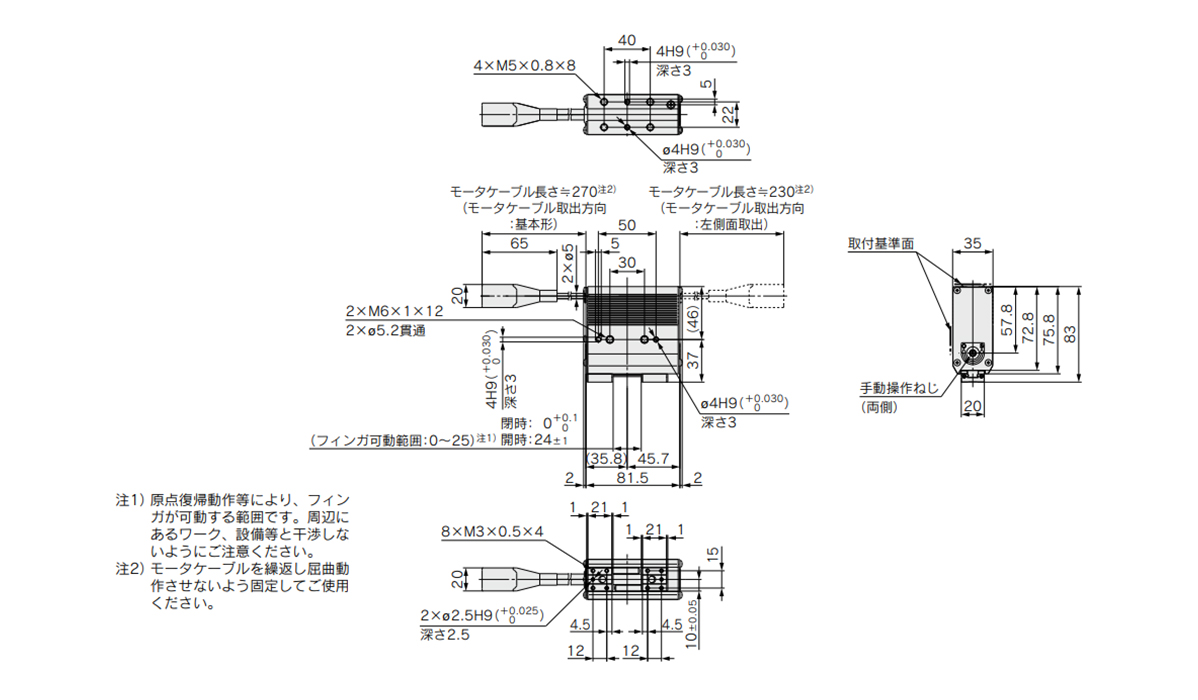

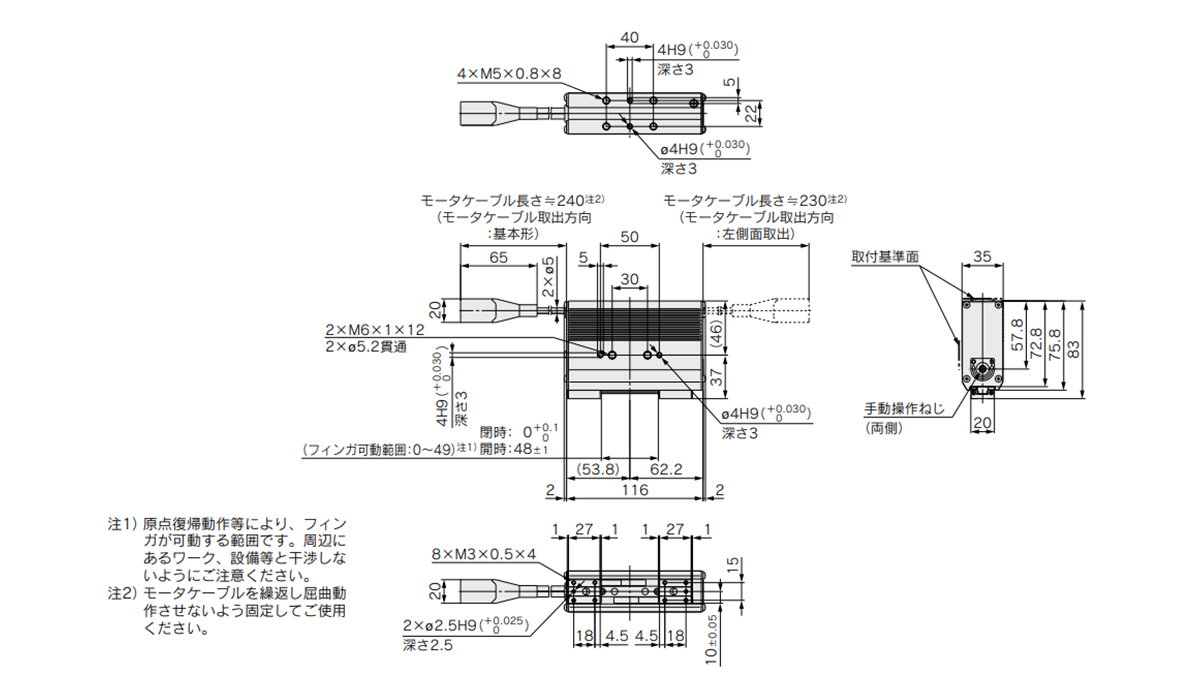

External dimensional drawing

(Unit: mm)

LEHF10K2-16 / basic dimensional drawing

LEHF10K2-32 / long stroke dimensional drawing

LEHF20K2-24 / basic dimensional drawing

LEHF20K2-48 / long stroke dimensional drawing

Common Cautions

*1 Range within which the finger can move when it returns to origin. Make sure the workpiece mounted on the finger does not interfere with the workpieces and equipment around the finger.

*2 Secure the motor cable so that it will not be bent repeatedly.

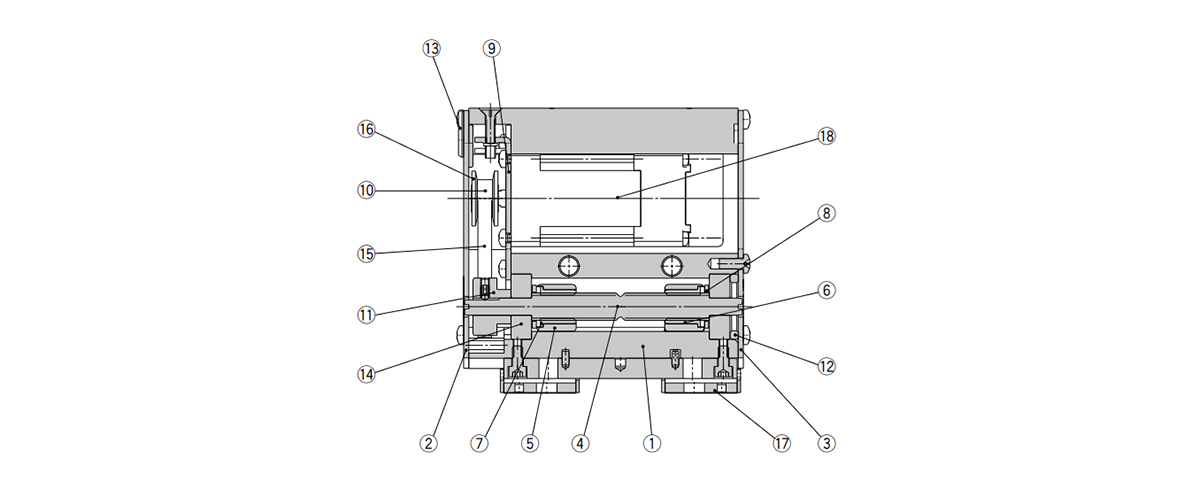

Structure drawing

LEHF Series structure drawing

| No. | Description | Material | Note |

|---|---|---|---|

| 1 | Body | Aluminum alloy | Anodized |

| 2 | Side plate A | Aluminum alloy | Anodized |

| 3 | Side plate B | Aluminum alloy | Anodized |

| 4 | Slide shaft | Stainless steel | Heat treated + Specially treated |

| 5 | Slide bushing | Stainless steel | – |

| 6 | Slide nut | Stainless steel | Heat treated + Specially treated |

| 7 | Slide nut | Stainless steel | Heat treated + Specially treated |

| 8 | Fixed plate | Stainless steel | – |

| 9 | Motor plate | Carbon steel | – |

| 10 | Pulley A | Aluminum alloy | – |

| 11 | Pulley B | Aluminum alloy | – |

| 12 | Bearing stopper | Aluminum alloy | – |

| 13 | Rubber bushing | NBR | – |

| 14 | Bearing | – | – |

| 15 | Belt | – | – |

| 16 | Flange | – | – |

| 17 | Finger assembly | – | – |

| 18 | Step motor (servo 24 V DC) | – | – |

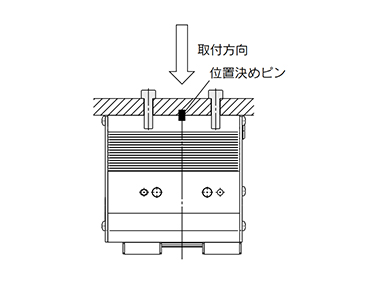

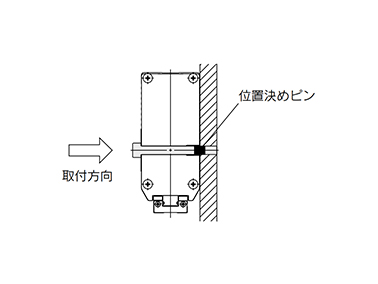

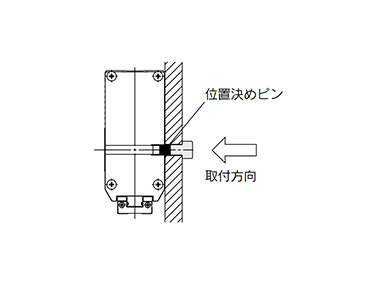

Mounting Method

When using the thread on the body

When using the thread on the mounting plate

When using the thread on the back of the body

Precautions

- *The parameters of the stroke and the open/close speed are for both fingers.

- *The stroke and the open/close speed for one finger is 1/2 the set parameter.

- *When gripping a workpiece by the product, be sure to set to “Pushing.”

- *Also, do not hit the workpiece with the finger and attachment during positioning or in the range of positioning. Otherwise, the lead screw can get caught and this may result in a malfunction. However, if the workpiece cannot be gripped when pushing (such as if the workpiece is a plastically deformed workpiece or rubber component, etc.), grip it when positioning giving consideration to the elastic force of the workpiece.

- *There is no effect on the backlash during pushing.

- *The return to origin is done by pushing. The finger position can be displaced by the effect of the backlash during positioning. This backlash displacement should be considered when setting the position.

- *See the manufacturer’s catalog for product information other than the above.

- *Product images are representative images.

Basic Information

| Type | Main Body(Electric Type) | Gripping Methods | Pinch, Parallel Type / Open, Parallel Type | Number of Fingers | 2 pcs. |

|---|---|---|---|---|---|

| Main Body Shape | Lateral Shape | Dimensions when closed(mm) | 0 | Environment, Applications | Standard |

| Additional Functions | With Linear Guide | Stroke Adjustment Mechanism | Open/Close Dual Adjustment |

LEHF10K2-16-6N

LEHF10K2-16-6ND

LEHF10K2-16-6PD

LEHF10K2-16-AN1

LEHF10K2-16-R1

LEHF10K2-16-R1AN1

LEHF10K2-16-R1AP3D

LEHF10K2-16-R1MJ

LEHF10K2-16-R3

LEHF10K2-16-R3AN1

LEHF10K2-16-R3AN3

LEHF10K2-16-R3MJD

LEHF20K2-24

LEHF20K2-24-6N

LEHF20K2-24-6N1

LEHF20K2-24-6P

LEHF20K2-24-6P1

LEHF20K2-24-6P1D

LEHF20K2-24-6PD

LEHF20K2-24-MJS

LEHF20K2-24-R1

LEHF20K2-24-R1AN

LEHF20K2-24-R1AN1

LEHF20K2-24-R1AN1D

LEHF20K2-24-R1AP3D

LEHF32K2-32-6N

LEHF32K2-32-6ND

LEHF32K2-32-6PD

LEHF32K2-32-MJS

LEHF32K2-32-R1

LEHF32K2-32-R3

LEHF32K2-32-R3AN1

LEHF32K2-32-R3AN1D

LEHF32K2-32-R3AN3

LEHF32K2-32-R3AN3D

LEHF32K2-32-R3MJD

LEHF32K2-32-R3MJS

LEHF32K2-32-R3MJTD

LEHF32K2-32-R5

LEHF32K2-32-R5AN

LEHF32K2-32-R5AN1

LEHF32K2-32-R5AN3

LEHF32K2-32-R5AP5D

LEHF40K2-40-6N1

LEHF40K2-40-6P1

LEHF40K2-40-6PD

LEHF40K2-40-APD

LEHF40K2-40-MJ

LEHF40K2-40-R1

LEHF40K2-40-R1AN

LEHF40K2-40-R1AN1

LEHF40K2-40-R1MJ

LEHF40K2-40-R3

LEHF40K2-40-R3AN1

LEHF40K2-40-R3AN1D

LEHF40K2-40-R3AN3D

LEHF40K2-40-R3MJD

LEHF40K2-40-R3MJS

LEHF40K2-40-R3MJT

LEHF40K2-40-R3MJTD

LEHF40K2-40-R5

LEHF40K2-40-R5AN

LEHF40K2-40-R5AN1

LEHF40K2-40-R5AN3D

LEHF40K2-40-R5AP1D

Giới thiệu SMC Việt Nam

SMC là thương hiệu hàng đầu thế giới trong lĩnh vực công nghệ khí nén, cung cấp các giải pháp tiên tiến nhằm hỗ trợ tự động hóa và tối ưu hóa quy trình sản xuất.

Với nền tảng vững chắc trong ngành, SMC Việt Nam luôn đi đầu trong việc nghiên cứu, đổi mới và phát triển sản phẩm, góp phần nâng cao năng suất và tiết kiệm lao động cho các doanh nghiệp công nghiệp.

Với phương châm “đóng góp vào tự động hóa và tiết kiệm lao động trong ngành công nghiệp”, SMC Việt Nam không ngừng cải tiến và mang đến những sản phẩm công nghệ tiên tiến nhất.

SMC Việt Nam cam kết cung cấp những giải pháp hiện đại, giúp khách hàng duy trì lợi thế cạnh tranh trên thị trường.

Medin Company cung cấp các sản phẩm SMC tại Việt Nam.

Đa dạng các sản phẩm và giải pháp khí nén phục vụ cho nhiều ngành công nghiệp khác nhau, bao gồm:

- Xy lanh khí nén – Giúp kiểm soát chuyển động chính xác và hiệu quả.

- Van điện từ – Ứng dụng rộng rãi trong điều khiển luồng khí nén.

- Bộ lọc khí nén – Đảm bảo chất lượng khí nén tối ưu.

- Cảm biến và bộ điều khiển – Tăng cường tự động hóa trong quy trình sản xuất.

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.