Xi Lanh Khí Nén SMC MUW Series MDUWB25 MDUWB32 40/50/63

MUW Series Plate Cylinder: Double Acting, Double Rod Specifications

Compact cylinder that allows small auto switches to be mounted in 4 directions.

Download

Xi Lanh Khí Nén SMC MUW Series MDUWB25 MDUWB32 40/50/63

MUW Series Plate Cylinder: Double Acting, Double Rod Specifications

[Features] · Designed so that the auto switches do not project out. · Facilitates the mounting of an auto switch.· Reduction of labor for work.

· Available with a stroke up to 300 mm.

· Width: up to 62% smaller (compared to CA2 cylinder).

· Can be mounted in flexible ways without needing brackets.

· Can be mounted with a short pitch.

· Various brackets are available to accommodate a wide range of applications.

· 2-color indicator solid state auto switch.

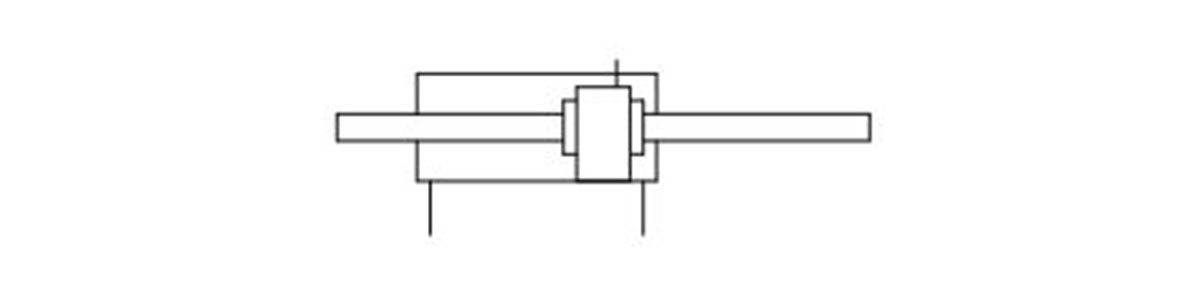

Symbol: rubber bumper (oval piston)

| Tube Inner Diameter (mm) | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|

| Action | Double acting, double rod | ||||

| Fluid | Air | ||||

| Proof Pressure | 1.05 MPa | ||||

| Maximum operating pressure | 0.7 MPa | ||||

| Minimum operating pressure | 0.05 MPa | ||||

| Ambient and Fluid Temperature | -10 to +60 ℃ | ||||

| Lubrication | Not required (non-lubricated) | ||||

| Piston Speed | 50 to 500 mm/s | ||||

| Stroke Length Tolerance | 0 to +1.4 | ||||

| Cushioning | Rubber cushion | ||||

| Mounting | Foot Type, Rod-End Flange Type | ||||

| Allowable rotational torque | 0.25 N·m | 0.55 N·m | 1.25 N·m | 2.0 N·m | |

| Rod non-rotating accuracy | ±1 ° | ±0.8 ° | ±0.5 ° | ||

Diagram

Diagram: MUW Series

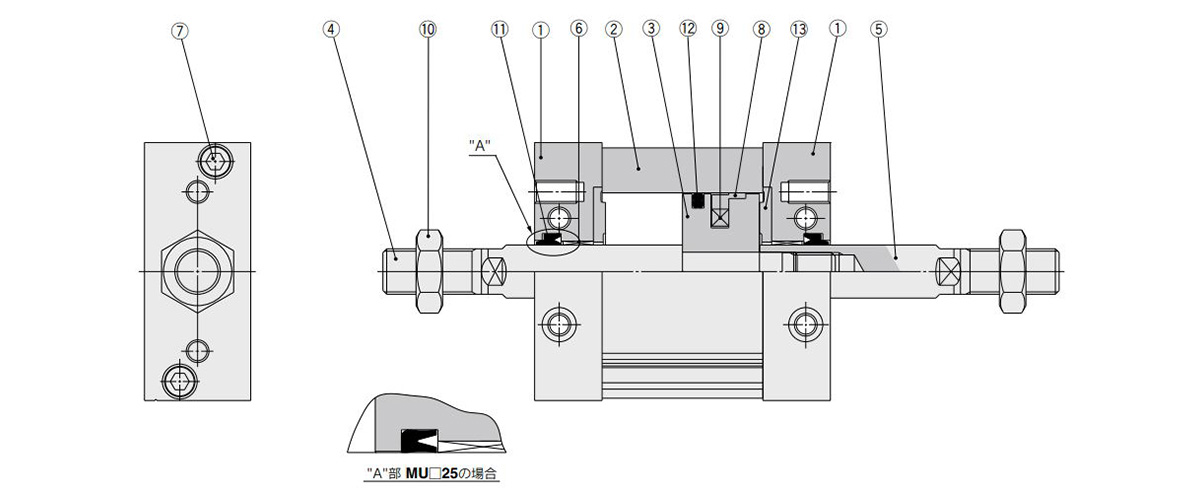

Components

| Number | Name | Material | Notes |

|---|---|---|---|

| 1 | Rod cover | Aluminum alloy | Anodized aluminum |

| 2 | Cylinder Tube | Aluminum alloy | Hard anodized aluminum |

| 3 | Piston | Aluminum alloy | Chromate |

| 4 | Piston rod A | Carbon steel | Hard chrome plated |

| 5 | Piston rod B | Carbon steel | Hard chrome plated |

| 6 | Bushing | Resin/Copper alloy (Multiple layers) | – |

| 7 | Hex Socket Head Cap Screw | Stainless steel | – |

| 8 | Wear ring | Resin | – |

| 9 | Magnet | – | Only built-in magnet type |

| 10 | Rod end nut | Rolled steel | Only attached to the rod-end male thread |

| 11 | Rod packing | NBR | – |

| 12 | Piston packing | NBR | – |

| 13 | Damper | NBR | – |

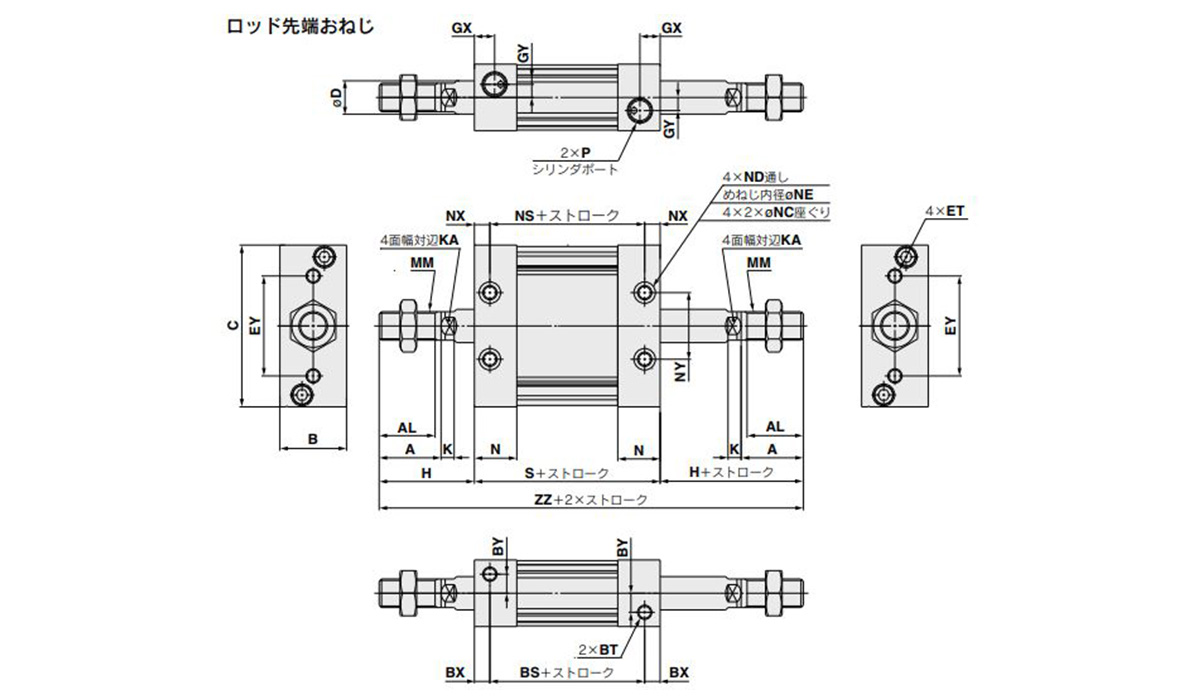

Dimensional drawing

Basic type: MUWB

Dimensional drawings: rod end male thread

(Units: mm)

| Model | Stroke range (mm) |

A | AL | B | BS | BT | BX | BY | C | D | ET | EY | GX | GY | H | K | KA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MUWB25 | 5 to 300 | 22 | 19.5 | 24 | 37 | M5 × 0.8 depth 7.5 | 9 | 7 | 54 | 12 | M5 × 0.8 depth 11 | 26 | 10 | 5 | 36 | 5.5 | 10 |

| MUWB32 | 5 to 300 | 26 | 23.5 | 28 | 45 | M6 × 1 depth 12 | 6.5 | 8 | 68 | 14 | M6 × 1 depth 11 | 42 | 8.5 | 5.5 | 40 | 5.5 | 12 |

| MUWB40 | 5 to 300 | 30 | 27 | 32 | 44 | M8 × 1.25 depth 13 | 8 | 9 | 86 | 16 | M8 × 1.25 depth 11 | 54 | 9 | 7 | 45 | 6 | 14 |

| MUWB50 | 5 to 300 | 35 | 32 | 39 | 54 | M10 × 1.5 depth 14.5 | 10 | 9 | 104 | 20 | M10 × 1.5 depth 15 | 64 | 11.5 | 8 | 53 | 7 | 18 |

| MUWB63 | 5 to 300 | 35 | 32 | 50 | 53 | M12 × 1.75 depth 18 | 11 | 12 | 124 | 20 | M12 × 1.75 depth 15 | 72 | 11.5 | 10 | 56 | 7 | 18 |

(Units: mm)

| Model | MM | N | NC | ND | NE | NS | NX | NY | P | S | ZZ | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| – | TN | TF | |||||||||||

| MUWB25 | M10 × 1.25 | 16.5 | 7.5 depth 4.5 | M5 × 0.8 | 4.3 | 43 | 6 | 26 | M5 × 0.8 | – | – | 55 | 127 |

| MUWB32 | M12 × 1.25 | 18 | 9 depth 5.5 | M6 × 1 | 5.1 | 45 | 6.5 | 28 | Rc 1/8 | NPT 1/8 | G1/8 | 58 | 138 |

| MUWB40 | M14 × 1.5 | 18.5 | 10.5 depth 6.5 | M8 × 1.25 | 6.9 | 44 | 8 | 36 | Rc 1/8 | NPT 1/8 | G1/8 | 60 | 150 |

| MUWB50 | M18 × 1.5 | 24 | 13.5 depth 8.5 | M10 × 1.5 | 8.7 | 54 | 10 | 42 | Rc1/4 | NPT1/4 | G1/4 | 74 | 180 |

| MUWB63 | M18 × 1.5 | 24 | 17 depth 10.5 | M12 × 1.75 | 10.5 | 53 | 11 | 46 | Rc1/4 | NPT1/4 | G1/4 | 75 | 187 |

- *The positions of the 4 flats of the piston rod differ from the drawing. The positions of the 4 flats of the piston rod for the double rod type are not the same.

Warning

When removing or installing a workpiece using rod end threads, do so while securing the 4 flats on the removing or installing side.

If torque is applied to the piston rod without securing the 4 flats, the torque makes the connection threads inside loosen, which may cause an accident or malfunction.

- *See the manufacturer’s catalog for product information other than the above.

Basic Information

| Cylinder Operation Method | Double Acting | Rod Operation Method | Double rod | Main Body Shape | Plate Cylinder |

|---|---|---|---|---|---|

| Additional Function | Standard | Environment, Applications | Standard | Operating Temperature(°C) | -10::60 |

| End Locking | No | Valves | No | Operating Pressure(MPa) | 0.05::0.7 |

MDUWB25-5DMZ-M9BV

MDUWB25-5DZ

MDUWB25-5DZ-M9BVL

MDUWB25-5DZ-M9NV

MDUWB25-5DZ-M9NVL

MDUWB25-10DMZ

MDUWB25-10DMZ-M9B

MDUWB25-10DMZ-M9BL

MDUWB25-10DMZ-M9BSDPC

MDUWB32-5DMZ

MDUWB32-5DMZ-M9NVLS

MDUWB32-5DZ

MDUWB32-5DZ-A93VS

MDUWB32-5DZ-M9BV

MDUWB32-5DZ-M9NVM

MDUWB32-10DMZ

MDUWB32-10DMZ-A90V

MDUWB32-10DMZ-A93V

MDUWB32-10DMZ-A93VS

MDUWB32-10DMZ-M9BL

MDUWB32-10DMZ-M9BM

MDUWB40-5DZ-M9BVL

MDUWB40-10DMZ

MDUWB40-10DMZ-A93V

MDUWB40-10DMZ-M9BL

MDUWB40-10DMZ-M9BV

MDUWB40-10DZ

MDUWB40-10DZ-A93L

MDUWB40-10DZ-A93V

MDUWB40-10DZ-A93VL

MDUWB40-10DZ-M9BL

MDUWB40-10DZ-M9BV

MDUWB40-10DZ-M9BVL

MDUWB40-10DZ-M9BVS

MDUWB50-5DMZ

MDUWB50-5DZ

MDUWB50-5DZ-M9BVL

MDUWB50-5DZ-M9BVS

MDUWB50-10DMZ

MDUWB50-10DMZ-M9BL

MDUWB50-10DZ

MDUWB50-10DZ-A93

MDUWB50-10DZ-A93L

MDUWB50-10DZ-M9BVL

MDUWB50-10DZ-M9BVS

MDUWB50-10DZ-M9NVS

MDUWB50-10DZ-M9NVSAPC

MDUWB63-5DMZ-M9BVLS

MDUWB63-5DMZ-M9NV

MDUWB63-5DZ

MDUWB63-5DZ-M9BVL

MDUWB63-10DMZ

MDUWB63-10DMZ-M9BL

MDUWB63-10DMZ-M9BV

MDUWB63-10DMZ-M9NV

MDUWB63-10DZ

MDUWB63-10DZ-M9B

MDUWB63-10DZ-M9BV

MDUWB63-15DMZ

MDUWB63-15DMZ-A93L

MDUWB63-15DMZ-M9BL

MDUWB63-15DMZ-M9BW

MDUWB63-15DZ

MDUWB63-15DZ-A93

MDUWB63-15DZ-A93L

MDUWB63-15DZ-M9BL

MDUWB63-15DZ-M9BVL

MDUWB63-15DZ-M9BVLS

MDUWB63-20DMZ

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Là Đại lý uỷ quyền của SMC tại Việt Nam.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.

👉 Nếu bạn có bất kỳ yêu cầu nào, vui lòng liên hệ với chúng tôi.

☎️ Hotline: 0902782082

![]() 3 Chi nhánh tại HCM, HN, Đà Nẵng

3 Chi nhánh tại HCM, HN, Đà Nẵng

👉 Tham khảo thêm bài viết trên Fanpage

👉 Tham khảo thêm video tại kênh Youtube