Xi Lanh SMC Air Cylinder CA2 Series CA2BFH40 CA2BH40 CA2BFH50 CA2BH50

Air Cylinder, Air-Hydro Type, Double Acting, Single Rod CA2 Series

An air cylinder with easy air cushion control.

Download

Xi Lanh SMC Air Cylinder CA2 Series CA2BFH40 CA2BH40 CA2BFH50 CA2BH50

Air-Hydro Cylinder, Double Acting, Single Rod CA2□H Series Specifications – Xi Lanh Khí Nén SMC

[Features] · Weight reduced by up to 15%.· Various switches such as compact auto switches and strong magnetic field resistant switches can be mounted.

· Part numbers are set for products with rod-end brackets and pivot brackets. (No need to order separately.)

*See the manufacturer’s catalog for detailed specifications.

*Product pictures are representations. CAD data is not supported for some model numbers.

Air Cylinder, Air-Hydro Type, Double Acting, Single Rod CA2□H Series external appearance

Symbol Double acting / Without cushion

Specifications

| Tube Internal Diameter (mm) | 40 | 50 | 63 | 80 | 100 |

|---|---|---|---|---|---|

| Type | Air-hydro type | ||||

| Applicable fluids | Turbine oil | ||||

| Operating method | Double acting | ||||

| Proof pressure | 1.5 MPa | ||||

| Maximum operating pressure | 1.0 MPa | ||||

| Ambient temperature and working fluid temperature | 5°C to 60°C | ||||

| Minimum operating pressure | 0.1 MPa | ||||

| Operating piston speed | 0.5 to 300 mm/s | ||||

| Cushioning | None | ||||

| Stroke length tolerance | Up to 250st: (0 to +1.0) 251 to 1,000st: (0 to +1.4) 1,001 to 1,500st: (0 to +1.8) | ||||

| Mounting style | Basic type, foot type, rod-end flange type, head-end flange type single clevis type, double clevis type, center trunnion type |

||||

Standard Strokes

For types with auto switch, also refer to the table of minimum strokes for auto switch mounting.

(Unit: mm)

| Tube I.D. | Standard stroke | Long stroke (L, F only) |

|---|---|---|

| 40 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500 | 800 |

| 50, 63 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600 | 1,200 |

| 80, 100 | 25, 50, 75, 100, 125, 150, 175, 200, 250, 300, 350, 400, 450, 500, 600, 700 | ø80 (80‑mm diameter): 1,400 ø100 (100‑mm diameter): 1,500 |

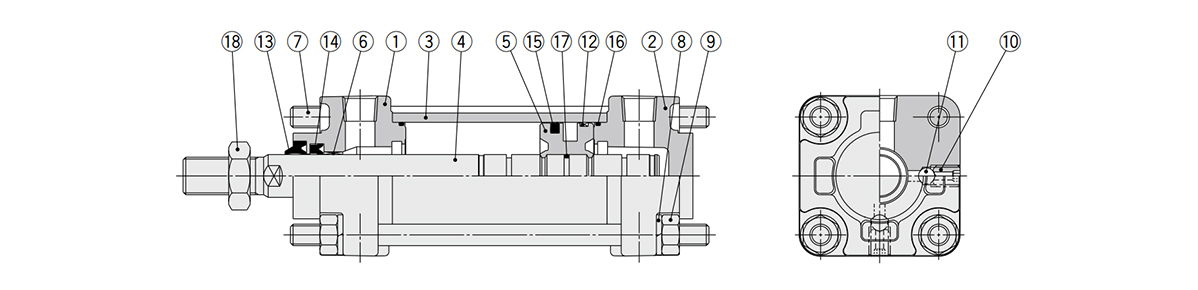

Structural drawing

Air Cylinder, Air-Hydro Type, Double Acting, Single Rod CA2□H Series Structural Drawing

Component Parts

| Number | Description | Material | Note |

|---|---|---|---|

| 1 | Rod Cover | Aluminum Alloy | Metallic painted |

| 2 | Head cover | Aluminum Alloy | Metallic painted |

| 3 | Cylinder tube | Aluminum Alloy | Hard Anodize |

| 4 | Piston rod | Carbon steel | Hard chrome plating |

| 5 | Piston | Aluminum Alloy | Chromate |

| 6 | Bushing | Resin/Copper alloy (Multiple layers) | – |

| 7 | Tie-rod | Carbon steel | Trivalent zinc chromated |

| 8 | Spring washer | Rolled steel | Trivalent zinc chromated |

| 9 | Tie-rod nut | Rolled steel | Trivalent zinc chromated |

| 10 | Air bleeding valve | Chrome Molybdenum Steel | Black zinc chromated |

| 11 | Check ball | Bearing steel | – |

| 12 | Wear ring | Resin | – |

| 13 | Scraper | NBR | – |

| 14 | Rod Gasket | NBR | – |

| 15 | Piston Gasket | NBR | – |

| 16 | Cylinder tube gasket | NBR | – |

| 17 | Piston gasket | NBR | – |

| 18 | Rod-end nut | Rolled steel | Trivalent zinc chromated |

*Do not disassemble the trunnion type. Refer to the catalog.

CA2BFH40-125

CA2BFH40-250

CA2BFH40-300

CA2BFH40-350

CA2BFH40-400

CA2BFH40-430

CA2BH40-1

CA2BH40-4

CA2BH40-5

CA2BH40-6

CA2BH40-8

CA2BH40-9

CA2BH40-10

CA2BH40-15

CA2BH40-20

CA2BH40-25

CA2BH40-25J

CA2BH40-25K

CA2BH40-30

CA2BH40-30K

CA2BH40-35J

CA2BH40-40

CA2BH40-50

CA2BH40-50J

CA2BH40-50K

CA2BH40-55

CA2BH40-55J

CA2BH40-60

CA2BH40-75

CA2BH40-80

CA2BH40-85

CA2BH40-90

CA2BFH50-100J

CA2BFH50-300

CA2BFH50-350

CA2BFH50-400

CA2BFH50-600

CA2BH50-1

CA2BH50-2

CA2BH50-3

CA2BH50-4

CA2BH50-5

CA2BH50-6

CA2BH50-7

CA2BH50-8

CA2BH50-9

CA2BH50-15

CA2BH50-20

CA2BH50-25

CA2BH50-30

CA2BH50-30J

CA2BH50-31

CA2BH50-40

CA2BH50-40K

CA2BH50-45

CA2BH50-50

CA2BH50-50J

CA2BH50-60

CA2BH50-60J

CA2BH50-65

CA2BH50-70

CA2BH50-75

CA2BH50-75J

CA2BFH63-75

CA2BFH63-80

CA2BFH63-100

CA2BFH63-150

CA2BFH63-175

CA2BFH63-200

CA2BFH63-225

CA2BFH63-232

CA2BFH63-300

CA2BFH63-450

CA2BH63-1

CA2BH63-2

CA2BH63-5

CA2BH63-6

CA2BH63-7

CA2BH63-8

CA2BH63-10

CA2BH63-20

CA2BH63-25

CA2BH63-25J

CA2BH63-30

CA2BH63-40

CA2BH63-45

CA2BH63-50

CA2BH63-50J

CA2BH63-50K

CA2BH63-60

CA2BH63-68J

CA2BH63-70

CA2BH63-71

CA2BH63-75

CA2BFH80-125

CA2BFH80-150

CA2BFH80-175

CA2BFH80-200

CA2BFH80-200K

CA2BFH80-260

CA2BFH80-300

CA2BFH80-400

CA2BFH80-450

CA2BFH80-500

CA2BFH80-550

CA2BFH80-600

CA2BFH80-700

CA2BFH80TF-16

CA2BFH100-50

CA2BFH100-60

CA2BFH100-100

CA2BFH100-150

CA2BFH100-600

CA2BFH100-601

CA2BFH100-700

CA2BH100-3

CA2BH100-7

CA2BH100-8

CA2BH100-10

CA2BH100-14

CA2BH100-20

CA2BH100-25

CA2BH100-25J

Xi Lanh SMC Air Cylinder CA2 Series CA2BFH40 CA2BH40 CA2BFH50 CA2BH50 CA2BFH63 CA2BH63 CA2BFH80 CA2BFH100 CA2BH100

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.

👉 Công ty Medin hỗ trợ:

![]() Tư vấn giải pháp tối ưu

Tư vấn giải pháp tối ưu

![]() Có sẵn sản phẩm dùng thử

Có sẵn sản phẩm dùng thử

![]() Hỗ trợ test tận nơi

Hỗ trợ test tận nơi

👉 Nếu bạn có bất kỳ yêu cầu nào, vui lòng liên hệ với chúng tôi.

- Hotline: 0902782082

- 3 Chi nhánh tại HCM, Hà Nội, Đà Nẵng

👉 Tham khảo thêm bài viết trên Fanpage

👉 Tham khảo thêm video tại kênh Youtube