Xi Lanh Khí Nén SMC MXQ Series MXQ8C MXQ12C Air Slide Table

Air Slide Table, Single-Side Ported Type, MXQ□C Series

An air slid table with porting on one side.

Download

Xi Lanh Khí Nén SMC MXQ Series MXQ8C MXQ12C Air Slide Table

Xi Lanh Khí Nén SMC MXQ Series MXQ8C MXQ12C Air Slide TableAir Slide Table, Single-Side Ported Type, MXQ□C Series Specifications – Xi Lanh Khí Nén SMC

[Features] · The reduced table thickness reduces the overall height and weight.· Improved allowable kinetic energy.

· The table shape was designed in consideration of functionality and maintenance.

· Mounting dimensions are the same as the conventional MXQ Series.

· A wide range of stroke adjusters (option).

· Shorter length table available.

· Good switch visibility. (Only for 8‑mm and 12‑mm diameters)

· Thinner design.

| Cylinder Inner Diameter (mm) | 8 | 12 |

|---|---|---|

| Piping connection port diameter | M5 × 0.8 | |

| Fluid | Air | |

| Action | Double acting type | |

| Operating Pressure | 0.15 to 0.7 MPa * (End lock: 0.35 to 0.7 MPa) |

|

| Guaranteed Proof Pressure | 1.05 MPa | |

| Ambient Temperature and Operating Fluid Temperature | -10 to 60°C | |

| Operating Speed Range (Average Operating Speed) | 50 to 500 mm/s (Metal stopper with bumper: 50 to 300 mm/s) (Metal stopper: 50 to 200 mm/s) |

|

| Cushioning (without Stroke Adjuster) | Internal rubber cushioning | |

| Cushioning (with Stroke Adjuster) | Metal stopper with bumper, rubber stopper Shock absorber, metal stopper |

|

| Lubrication | Not required | |

| Auto Switch | Solid-state auto switch, reed type auto switch (2-wire type, 3-wire type) 2-color indicator solid state auto switch (2-wire type, 3-wire type) |

|

| Stroke Length Tolerance | 0 to +2 mm | |

Theoretical Output

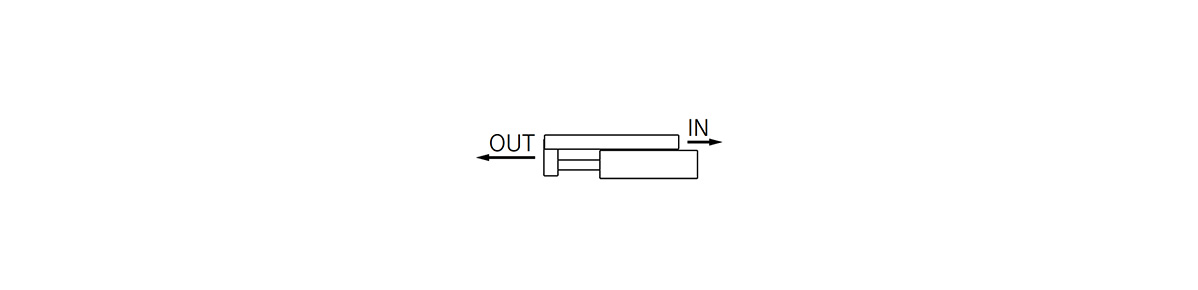

Operating direction (OUT/IN)

| Cylinder Internal Diameter (mm) |

Rod size (mm) |

Operating Direction | Piston area (mm2) |

Operating pressure (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|

| 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | ||||

| 8 | 4 | OUT | 101 | 20 | 30 | 40 | 51 | 61 | 71 |

| IN | 75 | 15 | 23 | 30 | 38 | 45 | 53 | ||

| 12 | 6 | OUT | 226 | 45 | 68 | 90 | 113 | 136 | 158 |

| IN | 170 | 34 | 51 | 68 | 85 | 102 | 119 | ||

(Unit: N)

Using dual rods provides double the output of conventional cylinders.

When using a metal stopper with a bumper for positioning, the theoretical output differs by the force required to fully compress the bumper.

Weight Table

| Model | Standard Stroke (mm) | Reduction of the shortened overall length type |

Additional Weight of Adjuster Option | Extension for Function Options | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | Extension end | Retraction end | Buffer | End Lock | Axial Piping | ||

| MXQ8C | 140 | 150 | 170 | 200 | 260 | 280 | – | – | – | -6 | 10 | 8 | 30 | 60 | No increase |

| MXQ12C | 280 | 290 | 320 | 370 | 400 | 550 | 620 | – | – | -12 | 20 | 16 | 70 | 60 | |

(Unit: g)

Centralized Adjuster Weight

| Model | Standard Stroke (mm) | Reduction of the retraction end adjuster only |

||||||

|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 75 | 100 | ||

| MXQ8C | 185 | 195 | 215 | 245 | 305 | 340 | – | -10 |

| MXQ12C | 365 | 385 | 415 | 465 | 495 | 645 | 715 | -20 |

(Unit: g)

Weight of Moving Parts

| Model | Standard Stroke (mm) | Reduction of the shortened overall length type |

Additional Weight of Adjuster Option | Extension for Function Options | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 20 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | Extension end | Retraction end | Buffer | End Lock | Axial Piping | ||

| MXQ8C | 68 | 76 | 85 | 97 | 116 | 138 | – | – | – | -6 | 10 | 8 | 30 | 10 | No increase |

| MXQ12C | 143 | 154 | 168 | 192 | 206 | 263 | 300 | – | – | -12 | 20 | 16 | 70 | 20 | |

(Unit: g)

Maximum Load Weight

| Model | Without Adjuster | Adjuster Options | ||||

|---|---|---|---|---|---|---|

| Internal Rubber Cushioning |

Rubber Stopper |

Metal Stopper with Bumper |

Shock Absorber / RJ | Metal Stopper |

||

| Horizontal | Vertical | |||||

| MXQ8C | 1 | 1 | 1 | 1 | 1 | |

| MXQ12C | 2 | 2 | 2 | 1.5 | 1 | 2 |

(Increment: kg)

Allowable Kinetic Energy

| Model | Without Adjuster | Adjuster Options | |||

|---|---|---|---|---|---|

| Internal Rubber Cushioning |

Metal Stopper Stopper |

Rubber Stopper |

Shock Absorber / RJ |

Metal Stopper |

|

| MXQ8C | 0.04 | 0.018 | 0.06 | 0.2 | 0.009 |

| MXQ12C | 0.11 | 0.04 | 0.12 | 0.33 | 0.02 |

(Unit: j)

Note that models cannot be selected using the allowable kinetic energy alone.

Basic Information

| Type | L-Shaped Table Type | Max. Load Mass (Horizontal Mounting)(kg) | 1~4.9 | Table Material | Aluminum |

|---|---|---|---|---|---|

| Guide Type | Linear guide type | Environment | General Purpose | Port Screw Type | M screw |

MXQ8C-10Z[1,2,3,4,5] MXQ8C-10ZA

MXQ8C-10ZA[3,6] MXQ8C-10ZB

MXQ8C-10ZB[2,3] MXQ8C-10ZBF

MXQ8C-10ZBF[3,6] MXQ8C-10ZBJ

MXQ8C-10ZBJ[3,6] MXQ8C-10ZBM

MXQ8C-10ZBM[3,6] MXQ8C-10ZC

MXQ8C-10ZC[3,6,8] MXQ8C-10ZD

MXQ8C-10ZD[3,6,8] MXQ8C-10ZE

MXQ8C-10ZE[1,2,3,4,5] MXQ8C-10ZEC

MXQ8C-10ZEC[3,6,8] MXQ8C-10ZEJ

MXQ8C-10ZEJ[3,6,8] MXQ8C-10ZEM

MXQ8C-10ZEM[3,6,8] MXQ8C-10ZF

MXQ8C-10ZF[3,6,8] MXQ8C-10ZG

MXQ8C-10ZG[3,6] MXQ8C-10ZH

MXQ8C-10ZH[2,3]

MXQ8C-20Z[1,2,3,4,5] MXQ8C-20ZA

MXQ8C-20ZA[3,6] MXQ8C-20ZB

MXQ8C-20ZB[2,3] MXQ8C-20ZBF

MXQ8C-20ZBF[3,6] MXQ8C-20ZBJ

MXQ8C-20ZBJ[3,6] MXQ8C-20ZBM

MXQ8C-20ZBM[3,6] MXQ8C-20ZC

MXQ8C-20ZC[3,6,8] MXQ8C-20ZD

MXQ8C-20ZD[3,6,8] MXQ8C-20ZE

MXQ8C-20ZE[1,2,3,4,5] MXQ8C-20ZEC

MXQ8C-20ZEC[3,6,8] MXQ8C-20ZEJ

MXQ8C-20ZEJ[3,6,8] MXQ8C-20ZEM

MXQ8C-20ZEM[3,6,8] MXQ8C-20ZF

MXQ8C-20ZF[3,6,8]

MXQ12C-10Z[1,2,3,4,5] MXQ12C-10ZA

MXQ12C-10ZA[3,6] MXQ12C-10ZB

MXQ12C-10ZB[2,3] MXQ12C-10ZBF

MXQ12C-10ZBF[3,6] MXQ12C-10ZBJ

MXQ12C-10ZBJ[3,6] MXQ12C-10ZBM

MXQ12C-10ZBM[3,6] MXQ12C-10ZC

MXQ12C-10ZC[3,6,8] MXQ12C-10ZD

MXQ12C-10ZD[3,6,8] MXQ12C-10ZE

MXQ12C-10ZE[1,2,3,4,5] MXQ12C-10ZEC

MXQ12C-10ZEC[3,6,8] MXQ12C-10ZEJ

MXQ12C-10ZEJ[3,6,8] MXQ12C-10ZEM

MXQ12C-10ZEM[3,6,8] MXQ12C-10ZF

MXQ12C-10ZF[3,6,8]

MXQ12C-20Z[1,2,3,4,5] MXQ12C-20ZA

MXQ12C-20ZA[3,6] MXQ12C-20ZB

MXQ12C-20ZB[2,3] MXQ12C-20ZBF

MXQ12C-20ZBF[3,6] MXQ12C-20ZBJ

MXQ12C-20ZBJ[3,6] MXQ12C-20ZBM

MXQ12C-20ZBM[3,6] MXQ12C-20ZC

MXQ12C-20ZC[3,6,8] MXQ12C-20ZD

MXQ12C-20ZD[3,6,8] MXQ12C-20ZE

MXQ12C-20ZE[1,2,3,4,5] MXQ12C-20ZEC

MXQ12C-20ZEC[3,6,8] MXQ12C-20ZEJ

MXQ12C-20ZEJ[3,6,8] MXQ12C-20ZEM

MXQ12C-20ZEM[3,6,8]

Giới thiệu SMC Việt Nam

SMC là thương hiệu hàng đầu thế giới trong lĩnh vực công nghệ khí nén, cung cấp các giải pháp tiên tiến nhằm hỗ trợ tự động hóa và tối ưu hóa quy trình sản xuất.

Với nền tảng vững chắc trong ngành, SMC Việt Nam luôn đi đầu trong việc nghiên cứu, đổi mới và phát triển sản phẩm, góp phần nâng cao năng suất và tiết kiệm lao động cho các doanh nghiệp công nghiệp.

Với phương châm “đóng góp vào tự động hóa và tiết kiệm lao động trong ngành công nghiệp”, SMC Việt Nam không ngừng cải tiến và mang đến những sản phẩm công nghệ tiên tiến nhất.

SMC Việt Nam cam kết cung cấp những giải pháp hiện đại, giúp khách hàng duy trì lợi thế cạnh tranh trên thị trường.

Medin Company cung cấp các sản phẩm SMC tại Việt Nam.

Đa dạng các sản phẩm và giải pháp khí nén phục vụ cho nhiều ngành công nghiệp khác nhau, bao gồm:

- Xy lanh khí nén – Giúp kiểm soát chuyển động chính xác và hiệu quả.

- Van điện từ – Ứng dụng rộng rãi trong điều khiển luồng khí nén.

- Bộ lọc khí nén – Đảm bảo chất lượng khí nén tối ưu.

- Cảm biến và bộ điều khiển – Tăng cường tự động hóa trong quy trình sản xuất.

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.