Xi Lanh Khí Nén SMC CY3B Series CY3B6 CY3B10 CY3B15 CY3B20 CY3B25 CY3B32 CY3B40

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series

The CY3B series is the basic type of the Magnetically Coupled Rodless Cylinder with improved bearing performance.

Download

Xi Lanh Khí Nén SMC CY3B Series CY3B6 CY3B10 CY3B15 CY3B20 CY3B25 CY3B32 CY3B40 CY3B50 CY3B63

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series Details – Xi Lanh Khí Nén SMC

[Features] · A good lubrication film is formed on the outer peripheral surface of the cylinder tube for improved durability.· Reduced sliding resistance.

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series, product image

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series Specifications

| Tube inner diameter (mm) | 6 | 10 | 15 | 20 | 25 | 32 | 40 | 50 | 63 |

|---|---|---|---|---|---|---|---|---|---|

| Usable fluids | Air | ||||||||

| Guaranteed pressure resistance | 1.05 MPa | ||||||||

| Maximum operating pressure | 0.7 MPa | ||||||||

| Minimum operating pressure | 0.16 | 0.16 | 0.16 | 0.16 | 0.15 | 0.14 | 0.12 | 0.12 | 0.12 |

| Ambient temperature and working fluid temperature | -10 to 60°C (however, no freezing) | ||||||||

| Operating piston speed | 50 to 500 mm/s | ||||||||

| Cushion | Rubber cushion | ||||||||

| Lubrication | Not required (lubrication-free) | ||||||||

| Allowable difference of stroke length (mm) | 0 to 250 st: (0 to +1.0), 251 to 1,000 st: (0 to +1.4), 1,001 st and above: (0 to +1.8) | ||||||||

| Mounting orientation | Horizontal, slanted, verticalNote) | ||||||||

| Mounting nuts (2 nuts) | Standard equipment (accessories) | ||||||||

| Magnetic retention force (N) | 19.6 | 53.9 | 137 | 231 | 363 | 588 | 922 | 1,471 | 2,256 |

Note: When mounting vertically, intermediate stopping using an air pressure circuit cannot be done.

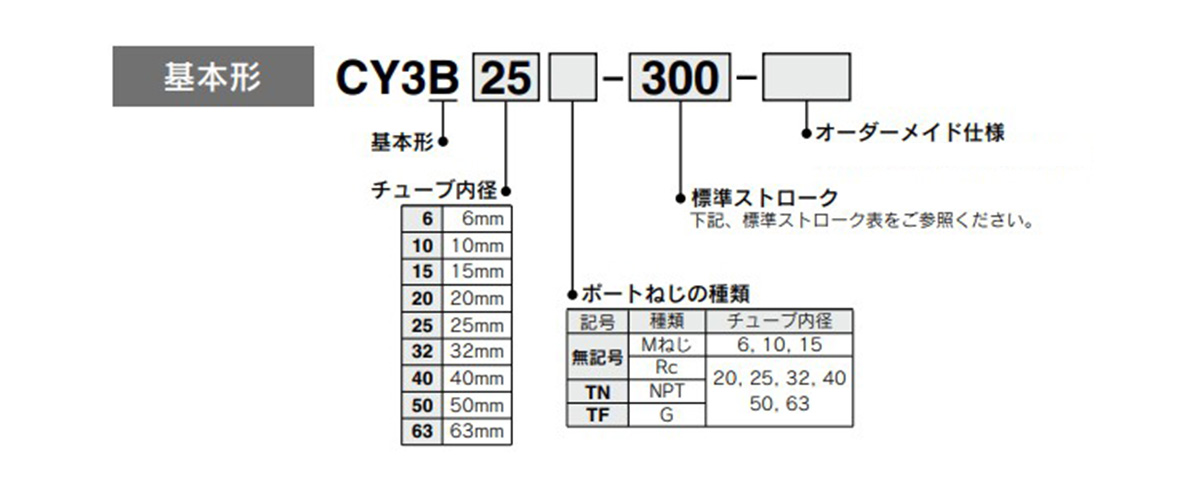

Model number indication method

Model number example

Standard stroke table

| Tube inner diameter (mm) |

Standard stroke (mm) | Manufacturable Maximum stroke (mm) |

|---|---|---|

| 6 | 50, 100, 150 and 200 | 300 |

| 10 | 50, 100, 150, 200, 250 and 300 | 500 |

| 15 | 50, 100, 150, 200, 250, 300, 350 400, 450, 500 |

1,000 |

| 20 | 100, 150, 200, 250, 300, 350, 400, 450 500, 600, 700, 800 |

1,500 |

| 25 | 3,000 | |

| 32 | ||

| 40 | 100, 150, 200, 250, 300, 350, 400, 450 500, 600, 700, 800, 900, 1,000 |

3,000 |

| 50 | 5,000 | |

| 63 |

- *Long stroke type (XB11) when the stroke exceeds 2,000 st.

- *The longer the stroke, the larger the amount of deflection in the cylinder tube. Pay attention to the mounting bracket and clearance value.

- *Intermediate stroke can be adjusted in 1‑mm increments.

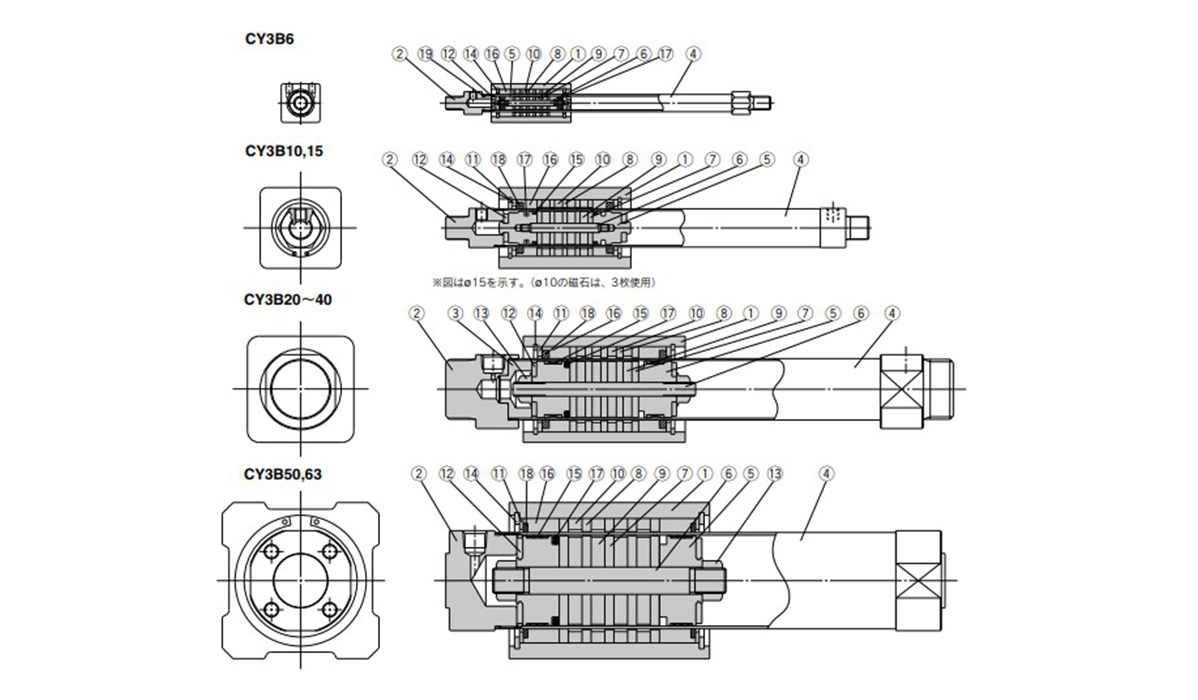

Structural Drawing

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series, structural drawing

Components

| Number | Part name | Materials | Additional notes | ||

|---|---|---|---|---|---|

| 1 | Body | Aluminum alloy | Hard anodized aluminum | ||

| 2 | Head cover | ø6 (diameter 6 mm), ø10 (diameter 10 mm) | Brass | – | |

| ø15 (diameter 15 mm) to ø63 (diameter 63 mm) | Aluminum alloy | ||||

| 3 | End collar | Aluminum alloy | ø20 to 40 (diameter 20 to 40 mm) only | ||

| 4 | Cylinder tube | Stainless steel | – | ||

| 5 | Piston | ø6 (diameter 6 mm) | Brass | ø6 (diameter 6 mm) | Electroless Ni plating |

| ø10 to 63 (diameter 10 to 63 mm) | Aluminum alloy | ø10 to 63 (diameter 10 to 63 mm) | Chromate | ||

| 6 | Shaft | Stainless steel | – | ||

| 7 | Piston-side yoke | Rolled steel | Zinc chromate | ||

| 8 | External moving element side yoke | Rolled steel | Zinc chromate | ||

| 9 | Magnet A | – | – | ||

| 10 | Magnet B | – | – | ||

| 11 | Spacer | Aluminum alloy | No ø6 (diameter 6 mm) | ||

| 12 | Damper | Urethane rubber | – | ||

| 13 | Piston nut | Carbon steel | No ø6 to 15 (diameter 6 to 15 mm) | ||

| 14 | C-type retaining ring for hole | Carbon tool steel | Phosphate coated | ||

| 15 | Wear ring A | Special resin | – | ||

| 16 | Wear ring B | Special resin | – | ||

| 17 | Piston packing | NBR | – | ||

| 18 | Lub-retainer | Special resin | No ø6 (diameter 6 mm) | ||

| 19 | Cylinder tube gasket | NBR | ø6 (diameter 6 mm) and ø10 (diameter 10 mm) only | ||

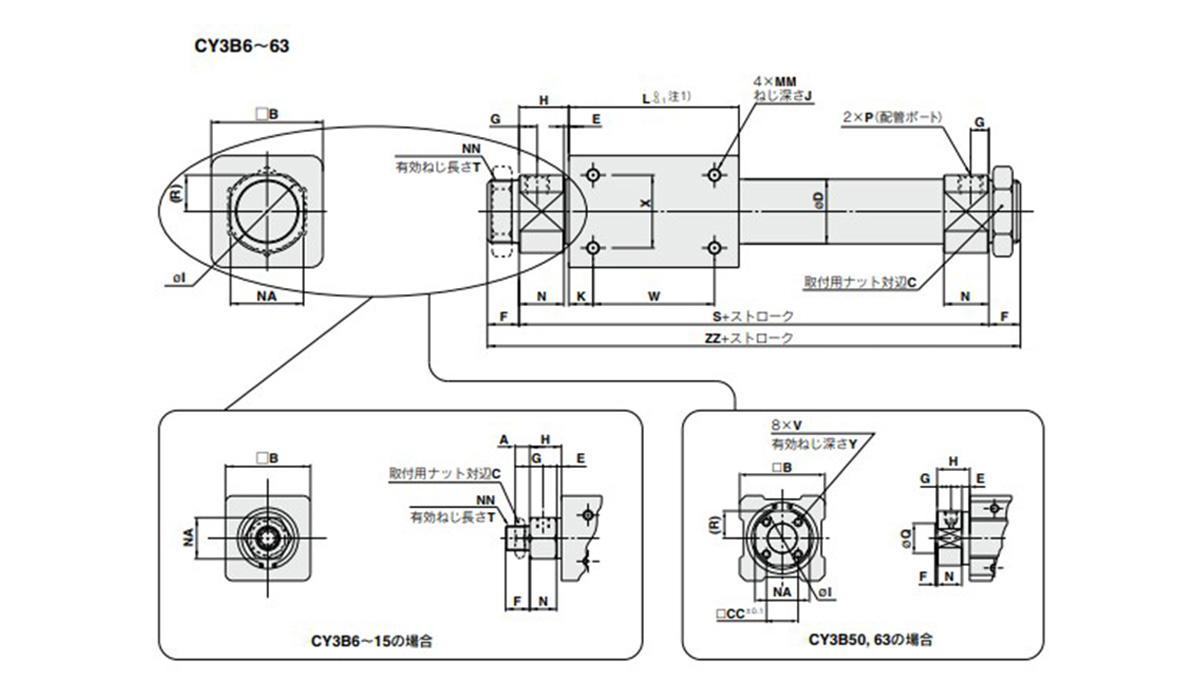

Magnetically Coupled Rodless Cylinder, Basic Type, CY3B Series, example dimensions

Basic type CY3B6 to CY3B63, dimensional drawing

Note 1: ø50 (diameter 50 mm) and ø63 (diameter 63 mm) are L (-0.2 to 0).

(Unit: mm)

| Model | A | B | C | CC | D | E | F | G | H | I | J | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CY3B6 | 4 | 17 | 8* | – | 7.6 | 4 | 8* | 5 | 13.5* | – | 4.5 | 5 | 35 |

| CY3B10 | 4 | 25 | 14 | – | 12 | 1.5 | 9 | 5 | 12.5 | – | 4.5 | 4 | 38 |

| CY3B15 | 4 | 35 | 14 | – | 16.6* | 2 | 10 | 5.5 | 13 | – | 6 | 11 | 57 |

| CY3B20 | 8 | 36 | 26 | – | 21.6* | 2* | 13 | 7.5* | 20 | 28 | 6 | 8 | 66 |

| CY3B25 | 8 | 46 | 32 | – | 26.4* | 2* | 13 | 7.5* | 20.5 | 34 | 8 | 10 | 70 |

| CY3B32 | 8 | 60 | 32 | – | 33.6* | 2* | 16 | 8* | 22 | 40 | 8 | 15 | 80 |

| CY3B40 | 10 | 70 | 41 | – | 41.6* | 3* | 16 | 11 | 29 | 50 | 10 | 16 | 92 |

| CY3B50 | – | 86 | – | 32 | 52.4* | 8 | 2 | 14 | 33 | 58* | 12 | 25 | 110 |

| CY3B63 | – | 100 | – | 38 | 65.4* | 8 | 2 | 14 | 33 | 72* | 12 | 26 | 122 |

| Model | MM | N | NA | NN | Q | R | S | T | V |

|---|---|---|---|---|---|---|---|---|---|

| CY3B6 | M3 × 0.5 | 9.5* | 10* | M6 × 1* | – | – | 62* | 6.5 | – |

| CY3B10 | M3 × 0.5 | 11 | 14 | M10 × 1 | – | – | 63 | 7.5 | – |

| CY3B15 | M4 × 0.7 | 11 | 17 | M10 × 1 | – | – | 83 | 8 | – |

| CY3B20 | M4 × 0.7 | 18* | 24 | M20 × 1.5 | – | 12* | 106 | 10 | – |

| CY3B25 | M5 × 0.8 | 18.5* | 30 | M26 × 1.5 | – | 15* | 111 | 10 | – |

| CY3B32 | M6 × 1 | 20* | 36 | M26 × 1.5 | – | 18* | 124 | 13 | – |

| CY3B40 | M6 × 1 | 26* | 46 | M32 × 2 | – | 23* | 150 | 13 | – |

| CY3B50 | M8 × 1.25 | 25 | 55 | – | 30 (-0.037 to -0.007) | 27.5* | 176 | – | M8 × 1.25 |

| CY3B63 | M8 × 1.25 | 25 | 69 | – | 32 (-0.043 to -0.007) | 34.5* | 188 | – | M10 × 1.5 |

(Unit: mm)

| Model | W | X | Y | ZZ | P (piping port) | ||

|---|---|---|---|---|---|---|---|

| No mark | TN* | TF* | |||||

| CY3B6 | 25 | 10 | – | 78* | M3 × 0.5* | – | – |

| CY3B10 | 30 | 16 | – | 81 | M5 × 0.8 | – | – |

| CY3B15 | 35 | 19 | – | 103 | M5 × 0.8 | – | – |

| CY3B20 | 50 | 25 | – | 132 | Rc 1/8 | NPT1/8 | G1/8 |

| CY3B25 | 50 | 30 | – | 137 | Rc 1/8 | NPT1/8 | G1/8 |

| CY3B32 | 50 | 40 | – | 156 | Rc 1/8 | NPT1/8 | G1/8 |

| CY3B40 | 60 | 40 | – | 182 | Rc 1/4 | NPT1/4 | G1/4 |

| CY3B50 | 60 | 60 | 16 | 180 | Rc 1/4 | NPT1/4 | G1/4 |

| CY3B63 | 70 | 70 | 16 | 192 | Rc 1/4 | NPT1/4 | G1/4 |

Note 2: Dimensions marked with “*” are different from the CY1B series.

Note 3: Mounting nuts can be screwed on only for the effective thread length of the head cover (T dimension). When mounting a cylinder, consider the thickness of flange, etc.

Basic Information

| Type | Rodless Cylinder | Table Material | Aluminum Alloy | Rodless Cylinder Joint Type | Magnetic |

|---|---|---|---|---|---|

| Table Surface Treatment | Hard Anodize | Guide Type | Prototype | Cushion | Rubber cushion |

CY3B6-20-X1468

CY3B6-20-XB13

CY3B6-25

CY3B6-27

CY3B6-30

CY3B6-35

CY3B6-40

CY3B6-45

CY3B6-45-X1468

CY3B6-45-XB13

CY3B6-50

CY3B6-50-X132

CY3B6-50-X1468

CY3B6-50-XB6

CY3B10-25

CY3B10-25-X324

CY3B10-30

CY3B10-30-X324

CY3B10-35

CY3B10-40

CY3B10-40-X324

CY3B10-40-XB13

CY3B10-44-XC24

CY3B10-45-X324

CY3B10-48-X324

CY3B10-49-X324

CY3B10-50

CY3B10-50-X132

CY3B15-25-XB6

CY3B15-28

CY3B15-30

CY3B15-30-X324

CY3B15-38

CY3B15-40

CY3B15-45

CY3B15-49

CY3B15-50

CY3B15-50-X132

CY3B15-50-X206

CY3B15-50-X322

CY3B15-50-XB6

CY3B20-25

CY3B20-27

CY3B20-30

CY3B20-30-X210

CY3B20-30-XB6

CY3B20-35

CY3B20-40

CY3B20-40-X132

CY3B20-40-X210

CY3B20-50

CY3B20-50-X160

CY3B20-50-X210

CY3B20-52

CY3B20-60

CY3B20-70

CY3B25-27

CY3B25-30

CY3B25-30-X322

CY3B25-40

CY3B25-49

CY3B25-50

CY3B25-50-X322

CY3B25-50-X324

CY3B25-50-XB6

CY3B25-55

CY3B25-61

CY3B25-63

CY3B25-70

CY3B25-75

CY3B32-36

CY3B32-37

CY3B32-40

CY3B32-40-X160

CY3B32-40-X210

CY3B32-45

CY3B32-45-X322

CY3B32-50

CY3B32-50-X132

CY3B32-50-X210

CY3B32-50-XB6

CY3B32-55

CY3B32-60

CY3B32-60-X322

CY3B32-60-X324

CY3B32-70

CY3B40-40-X210

CY3B40-40-X324

CY3B40-45

CY3B40-45-X160

CY3B40-50

CY3B40-50-X160

CY3B40-50-X210

CY3B40-50-X322

CY3B50-35

CY3B50-40

CY3B50-45

CY3B50-50

CY3B50-50-XB6

CY3B50-55

CY3B50-75

CY3B50-80

CY3B50-85

CY3B50-100

CY3B63-40-X322

CY3B63-40-X324

CY3B63-43-X322

CY3B63-43-X324

CY3B63-50

CY3B63-75

CY3B63-80

CY3B63-100

CY3B63-1000

CY3B63-1000-X116

Giới thiệu SMC Việt Nam

SMC là thương hiệu hàng đầu thế giới trong lĩnh vực công nghệ khí nén, cung cấp các giải pháp tiên tiến nhằm hỗ trợ tự động hóa và tối ưu hóa quy trình sản xuất.

Với nền tảng vững chắc trong ngành, SMC Việt Nam luôn đi đầu trong việc nghiên cứu, đổi mới và phát triển sản phẩm, góp phần nâng cao năng suất và tiết kiệm lao động cho các doanh nghiệp công nghiệp.

Với phương châm “đóng góp vào tự động hóa và tiết kiệm lao động trong ngành công nghiệp”, SMC Việt Nam không ngừng cải tiến và mang đến những sản phẩm công nghệ tiên tiến nhất.

SMC Việt Nam cam kết cung cấp những giải pháp hiện đại, giúp khách hàng duy trì lợi thế cạnh tranh trên thị trường.

Medin Company cung cấp các sản phẩm SMC tại Việt Nam.

Đa dạng các sản phẩm và giải pháp khí nén phục vụ cho nhiều ngành công nghiệp khác nhau, bao gồm:

- Xy lanh khí nén – Giúp kiểm soát chuyển động chính xác và hiệu quả.

- Van điện từ – Ứng dụng rộng rãi trong điều khiển luồng khí nén.

- Bộ lọc khí nén – Đảm bảo chất lượng khí nén tối ưu.

- Cảm biến và bộ điều khiển – Tăng cường tự động hóa trong quy trình sản xuất.

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.