Xi Lanh Khí Nén SMC Vacuum Rodless Cylinder CYV Series CYV15 CYV32

Vacuum Rodless Cylinder CYV Series

A low-dust-generation type air cylinder, usable for transport in vacuum environments.

Download

Xi Lanh Khí Nén SMC Vacuum Rodless Cylinder CYV Series CYV15 CYV32

[Features] · Being able to be placed in a vacuum chamber helps contribute to making more compact and simplified transport systems.· Stainless steel linear guide and low-dust-generation vacuum grease.

· Reduced initial dust generation for reduced dust generated at the stroke end.

· Uses a magnetic rodless cylinder which has no sliding-induced external leaks.

· Outgassing has been reduced by surface treatments and the plastic/resin materials eliminated.

· Tube internal diameter: 15 mm, Magnetic attractive force: 59 N. Piping connection port diameter: 5/16-24 UNF.

· Tube internal diameter: 32 mm, Magnetic attractive force: 268 N. Piping connection port diameter: 7/16-20 UNF.

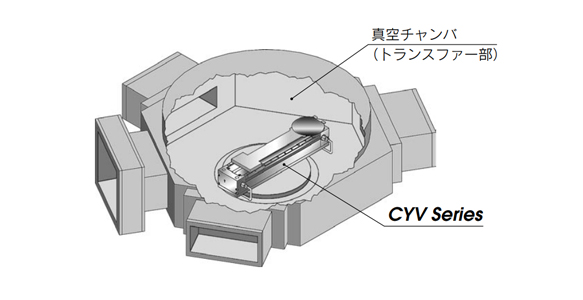

Vacuum Rodless Cylinder CYV Series external appearance

Vacuum Rodless Cylinder CYV Series example application

*The concept drawing above is an example showing how to install the cylinder. However, it is not to fulfill all the vacuum-chamber usage conditions.

Specifications

- Operating environment pressure: atmospheric to 1.3 × 10-4 Pa (ABS)

- Operating environment atmosphere (*1): air and inert gases

- Operating fluid (*1): air and inert gases

- Operation type: double action

- Guaranteed proof pressure: 0.5 MPa

- Operating pressure range: 0.05 to 0.3 MPa

- Leak amount: 1.3 × 10-7 Pa·m3/sec or less (at normal temperature, excluding gas permeation)

- Maximum baking temperature (*2, *3): 100°C

- Ambient and operating fluid temperature: -10 to +60°C (no freezing)

- Maximum operating piston speed (*4): 50 to 300 mm/s

- Stroke adjustable amount: Each side -2 to 0 mm (both sides -4 to 0 mm)

- Cushioning: sine cushion (air cushioning)

- Lubrication method: vacuum grease for linear guide and in cylinder tube

- *1 Air is recommended for the operating environment atmosphere and operating liquid. If using other inert gases, the product lifespan and other variables may vary. Contact the SMC support center for details.

- *2 This baking is limited to baking before cylinder operation. For cylinder operation, use a temperature range of -10 to +60°C.

- *3 Contact the SMC support center if the baking temperature is to exceed 100°C.

- *4 The operating piston speed above indicates the maximum speed. From the beginning of slide table movement at the stroke end until the end of the cushion stroke takes approx. 0.5 seconds (one side) or 1 second for both sides.

Weight List

CYV15 Standard Stroke

- 100 mm: 1.2 kg

- 150 mm: 1.4 kg

- 200 mm: 1.6 kg

- 250 mm: 1.7 kg

- 300 mm: 1.9 kg

- 350 mm: 2 kg

- 400 mm: 2.2 kg

- 450 mm: 2.4 kg

- 500 mm: 2.5 kg

- 600 mm: 2.8 kg

- 700 mm: 3.2 kg

CYV32 Standard Stroke

- 100 mm: 4.2 kg

- 150 mm: 4.6 kg

- 200 mm: 5 kg

- 250 mm: 5.5 kg

- 300 mm: 5.9 kg

- 350 mm: 6.3 kg

- 400 mm: 6.7 kg

- 450 mm: 7.1 kg

- 500 mm: 7.5 kg

- 600 mm: 8.3 kg

- 700 mm: 9.1 kg

Theoretical Output List

Tube Inner Diameter: 15 mm, Piston Area: 176 mm2 Theoretical Output

- Operating pressure 0.1 MPa: 18 N

- Operating pressure 0.2 MPa: 35 N

- Operating pressure 0.3 MPa: 53 N

Tube Inner Diameter: 32 mm, Piston Area: 804 mm2 Theoretical Output

- Operating pressure 0.1 MPa: 80 N

- Operating pressure 0.2 MPa: 161 N

- Operating pressure 0.3 MPa: 241 N

Product Features

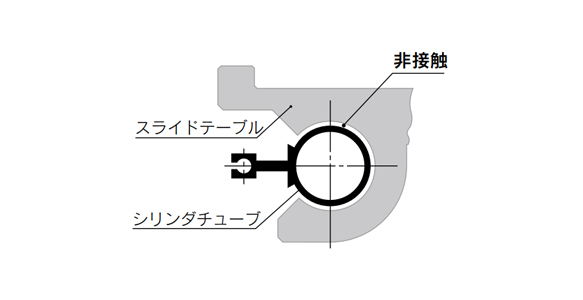

Its non-contact structure ensures no contact between the outer surface of the cylinder tube and the inner surface of the slide table, eliminating the generation of dust caused by sliding friction

Special cylinder tube, long stroke (max 700 mm)

Uses a special cylinder tube made of extruded aluminum

As the cylinder is directly attached to the rail base, there is no deflection, even with long strokes. The use of a linear guide ensures this non-contact structure

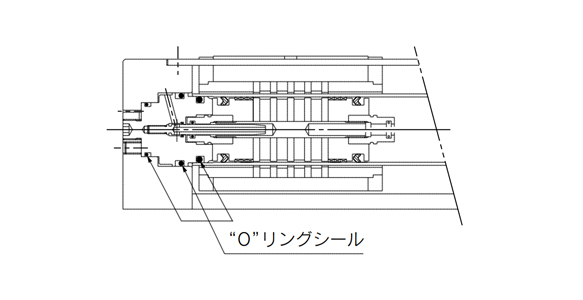

O-ring seals separate the vacuum and atmosphere

*To allow fine adjustments to be made to the stroke, O-rings are installed to separate the vacuum from the atmosphere. Contact SMC if you require a different sealing method.

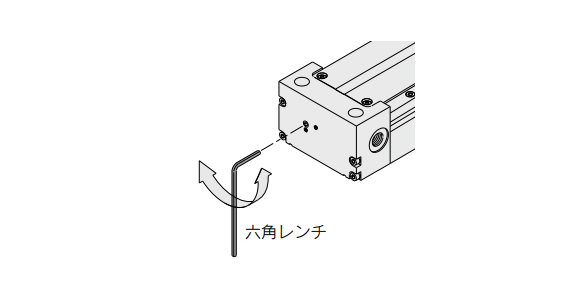

Can be fine-tuned at the end of the stroke

Fine adjustments can be made on one side (-2 to 0 mm) or both sides together (-4 to 0 mm)

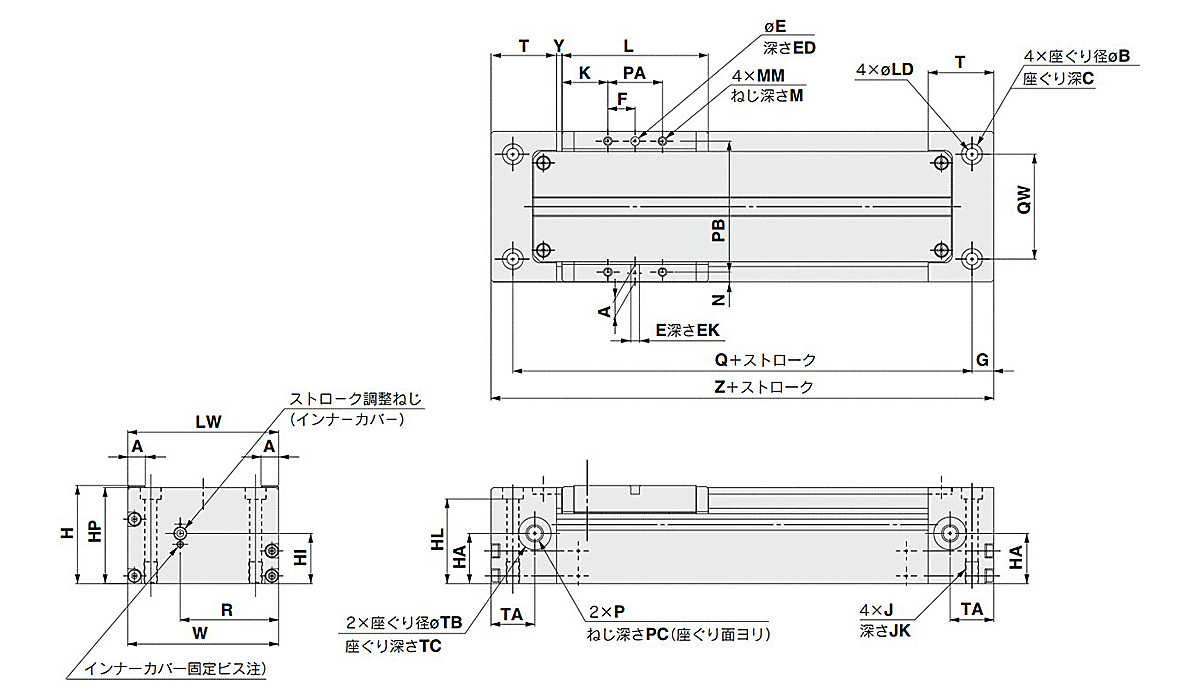

Product Drawing

(Unit: mm)

Vacuum Rodless Cylinder CYV Series dimensional drawing

| Model | A | B | C | E | ED | EK | F | G | H | HA | HI | HL | HP | J | JK | K | L | LD |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CYV15 | 8 | 10.5 | 6.4 | 6H9 (0 to +0.030) | 9.5 | 4 | 12.5 | 10 | 45 | 23 | 23 | 37.6 | 44 | M6 × 1 | 10 | 21 | 67 | 5.6 |

| CYV32 | 12 | 16 | 10.2 | 4H9 (0 to +0.030) | 13 | 6 | 25 | 9 | 75 | 39 | 39 | 63.3 | 73.5 | M10 × 1.5 | 12 | 20 | 90 | 9.2 |

| Model | LW | MM | M | N | P | PA | PB | PC | Q | QW | R | T | TA | TB | TC | W | Y | Z |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CYV15 | 69 | M4 × 0.7 | 6 | 4.5 | 5/16-24UNF | 25 | 60 | 10 | 112 | 48 | 45 | 30 | 20 | 15 | 0.5 | 69 | 2.5 | 132 |

| CYV32 | 115 | M6 × 1 | 8 | 7.5 | 7/16-20UNF | 50 | 100 | 12 | 147 | 83 | 79.5 | 34 | 22.5 | 20 | 0.5 | 115 | 3.5 | 165 |

*See the individual product notes in the SMC catalog (cushioning effect [sine cushion] and stroke adjustment).

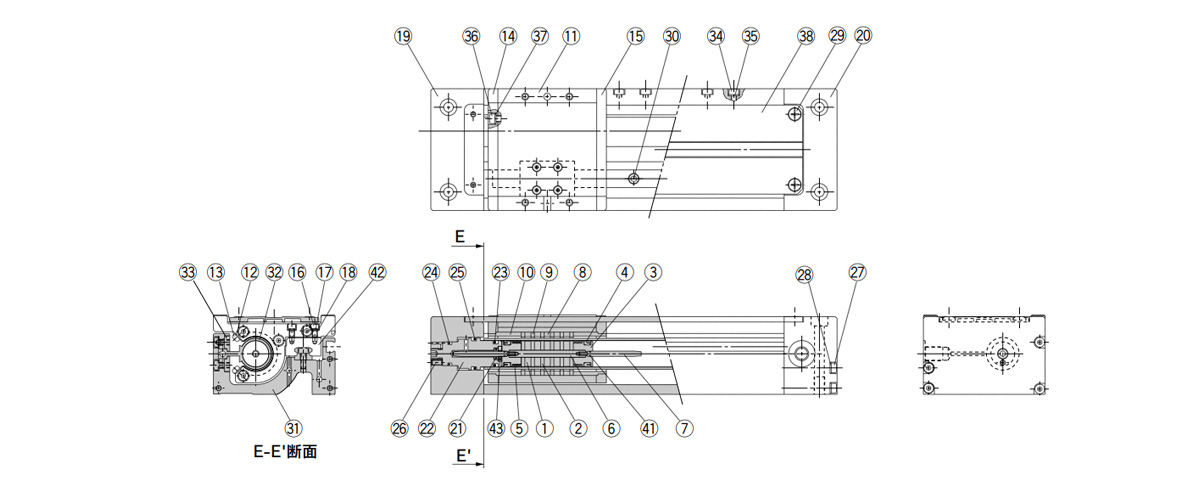

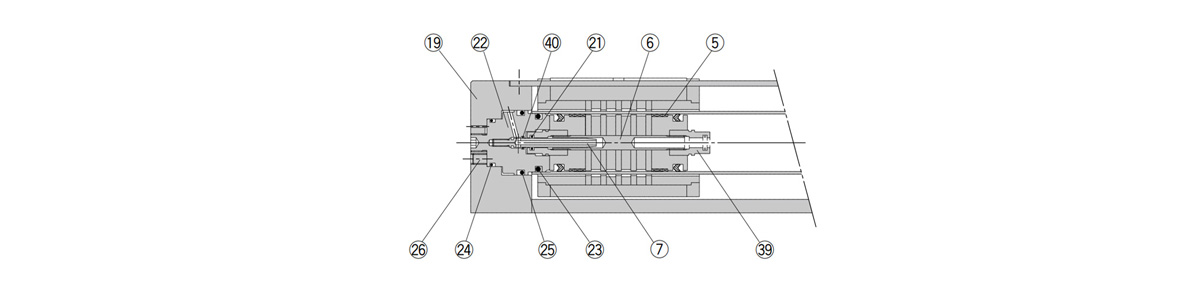

Product Structural Drawing

CYV15 structural drawing

CYV32 structural drawing

| Number | Part Name | Material | Note |

|---|---|---|---|

| 1 | Magnet A | – | – |

| 2 | Piston-Side Yoke | Rolled steel plate | Zinc chromate |

| 3 | Piston | Brass / aluminum alloy | Electroless nickel plating / chromate |

| 4 | Piston Seal | Fluororubber | – |

| 5 | Wear Ring | Special bearing | – |

| 6 | Shaft | Stainless steel | – |

| 7 | Cushion Ring | Stainless steel / brass | – / electroless nickel plating |

| 8 | Magnet B | – | Titanium nitride coating |

| 9 | External Slider Side Yoke | Rolled steel | Electroless nickel plating |

| 10 | Hold Spacer | Aluminum alloy | Electroless nickel plating |

| 11 | Slide Table | Aluminum alloy | Electroless nickel plating |

| 12 | Insertion Guide Plate | Stainless steel | – |

| 13 | Cross-Head Pan Head Screw | Stainless steel | – |

| 14 | Side Plate A | Aluminum alloy | Electroless nickel plating |

| 15 | Side Plate B | Aluminum alloy | Electroless nickel plating |

| 16 | Hexagon Socket Head Bolt | Stainless steel | – |

| 17 | Spring Washer | Stainless steel | – |

| 18 | Flat Washer | Stainless steel | – |

| 19 | Plate A | Aluminum alloy | Electroless nickel plating |

| 20 | Plate B | Aluminum alloy | Electroless nickel plating |

| 21 | Cushion Seal | Fluororubber | – |

| 22 | Inner Cover | Aluminum alloy | Electroless nickel plating |

| 23 | Cylinder Tube Gasket | Fluororubber | – |

| 24 | O-ring | Fluororubber | – |

| 25 | O-ring | Fluororubber | – |

| 26 | Hex Socket Head Set Screw | Stainless steel | – |

| 27 | Hexagon Socket Head Bolt | Stainless steel | – |

| 28 | Flat Washer | Stainless steel | – |

| 29 | Cross-Head Pan Head Screw | Stainless steel | – |

| 30 | Hexagon Socket Head Bolt | Stainless steel | – |

| 31 | Rail base | Aluminum alloy | Electroless nickel plating |

| 32 | Cylinder Tube | Aluminum alloy | Electroless nickel plating |

| 33 | Tube Attaching Bracket | Aluminum alloy | Electroless nickel plating |

| 34 | Hexagon Socket Head Bolt | Stainless steel | – |

| 35 | Flat Washer | Stainless steel | – |

| 36 | Hexagon Socket Head Bolt | Stainless steel | – |

| 37 | Flat Washer | Stainless steel | – |

| 38 | Top Cover | Aluminum alloy | Electroless nickel plating |

| 39 | Cushion Seal Holder | Aluminum alloy | Chromate |

| 40 | O-ring | Fluororubber | – |

| 41 | O-ring | Fluororubber | – |

| 42 | Linear Guide | Stainless steel | – |

| 43 | Holding Plate | Aluminum alloy | Hard anodized aluminum |

- *In the Materials and Notes columns of the list above, the first description is for CYV15, and the second description is for CYV32.

Precautions

- *Open the inner package of the double packaged clean series in a clean room or other clean environment.

- *Do not use bare hands to install the cylinder. Doing so can cause the outgassing characteristics to degrade.

- *Fully exhaust the compressed air in the piping outside of the clean room before replacing parts in the chamber or disassembling.

- *See the SMC catalog for product information other than that detailed above.

Basic Information

| Type | Rodless Cylinder | Table Material | Aluminum Alloy | Rodless Cylinder Joint Type | Magnetic |

|---|---|---|---|---|---|

| Environment | Vacuum | Table Surface Treatment | Electroless Nickel Plating | Guide Type | Linear guide type |

| Operating Speed(mm/s) | 50::300 | Operating Pressure(MPa) | 0.05 to 0.3 | Cushion | Sine cushion (air cushion) |

CYV15-100

CYV15-150

CYV15-200

CYV15-250

CYV15-300

CYV15-350

CYV15-400

CYV15-450

CYV15-500

CYV15-600

CYV15-700

CYV32-100

CYV32-150

CYV32-200

CYV32-250

CYV32-300

CYV32-350

CYV32-400

CYV32-450

CYV32-500

CYV32-600

CYV32-700

Giới thiệu SMC Việt Nam

SMC là thương hiệu hàng đầu thế giới trong lĩnh vực công nghệ khí nén, cung cấp các giải pháp tiên tiến nhằm hỗ trợ tự động hóa và tối ưu hóa quy trình sản xuất.

Với nền tảng vững chắc trong ngành, SMC Việt Nam luôn đi đầu trong việc nghiên cứu, đổi mới và phát triển sản phẩm, góp phần nâng cao năng suất và tiết kiệm lao động cho các doanh nghiệp công nghiệp.

Với phương châm “đóng góp vào tự động hóa và tiết kiệm lao động trong ngành công nghiệp”, SMC Việt Nam không ngừng cải tiến và mang đến những sản phẩm công nghệ tiên tiến nhất.

SMC Việt Nam cam kết cung cấp những giải pháp hiện đại, giúp khách hàng duy trì lợi thế cạnh tranh trên thị trường.

Medin Company cung cấp các sản phẩm SMC tại Việt Nam.

Đa dạng các sản phẩm và giải pháp khí nén phục vụ cho nhiều ngành công nghiệp khác nhau, bao gồm:

- Xy lanh khí nén – Giúp kiểm soát chuyển động chính xác và hiệu quả.

- Van điện từ – Ứng dụng rộng rãi trong điều khiển luồng khí nén.

- Bộ lọc khí nén – Đảm bảo chất lượng khí nén tối ưu.

- Cảm biến và bộ điều khiển – Tăng cường tự động hóa trong quy trình sản xuất.

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.