Xi Lanh Khí Nén SMC CY1S Series CY1S6 CY1S10 Magnetically Coupled Rodless Cylinder

Magnetically Coupled Rodless Cylinder, Slider Type: Slide Bearing, CY1S Series

Air slide table made by SMC

Download

Xi Lanh Khí Nén SMC CY1S Series CY1S6 CY1S10 Magnetically Coupled Rodless Cylinder

Specifications of Magnet Type Rodless Cylinder, Slider Type / Slide Bearing CY1S Series – Xi Lanh Khí Nén SMC

[Features] · Weight reduced by up to 15% (0.96 kg: conventionally 1.13 kg)· Overall length reduced by up to 15 mm (240 mm: conventionally 255 mm)

· The inner and outer peripheral surfaces of the cylinder tube are equipped with Lub-retainers to improve lubricity retention.

· Stroke position reproducibility is improved with an adjusting bolt

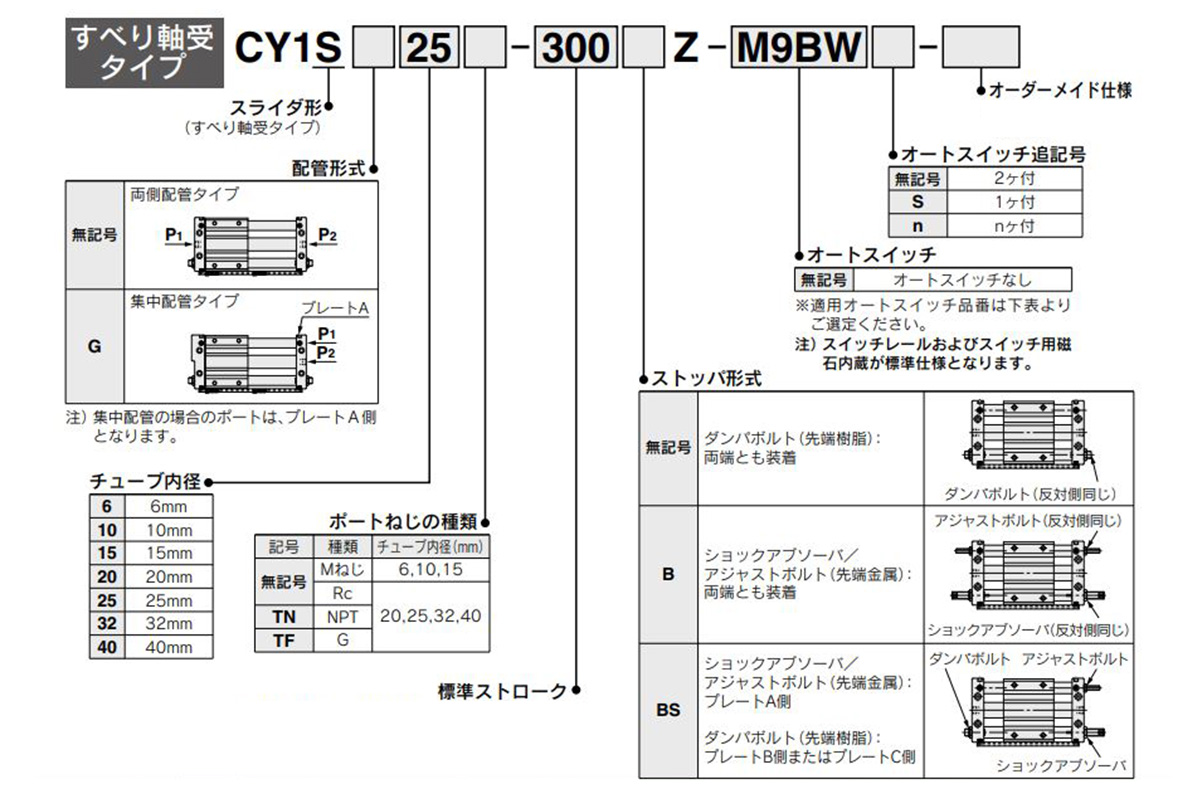

Model Number Notation

How to order: image

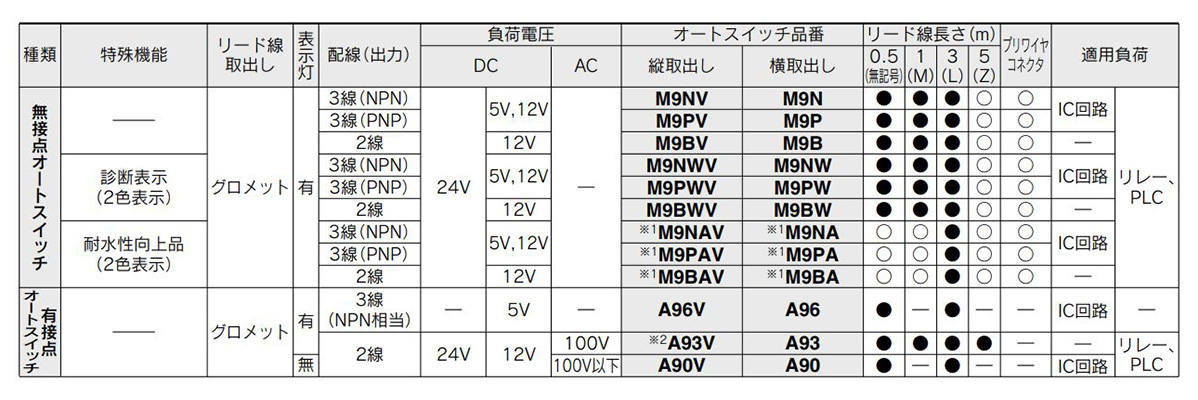

Applicable auto switches

Applicable auto switch part number identification, reference

- * 1The water resistant type auto switch can be mounted on the above models, but it does not guarantee the water-resistant performance of the product.

Check with the manufacturer regarding water-resistant types for the above model numbers. - * 2Lead wire length 1 m type is only compatible with D-A93.

- *Auto switches are shipped together (but not assembled).

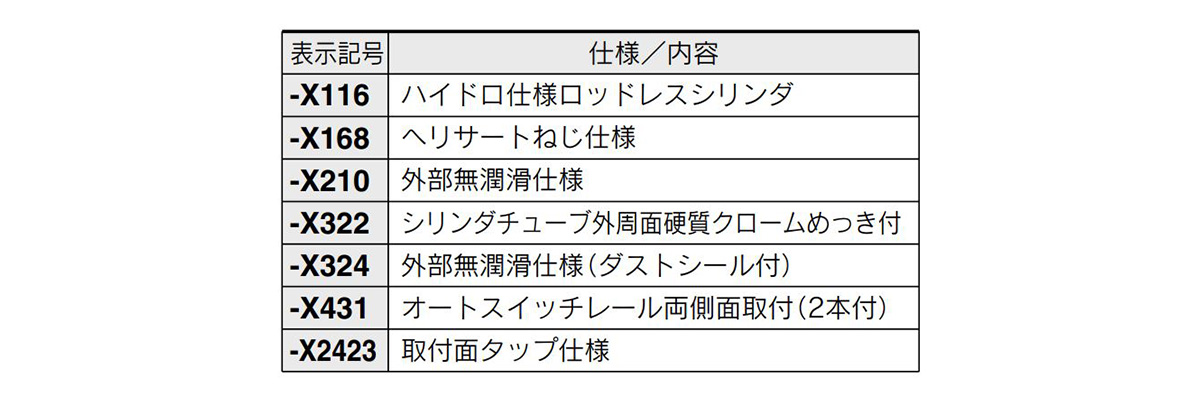

Individual Made-to-Order Specifications

Reference for identifying the part number of individually made-to-order specifications

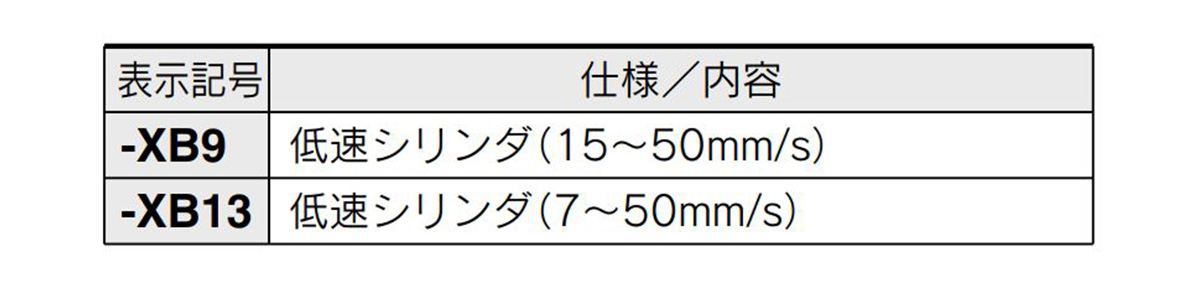

Made to Order Specifications

Reference for identifying the part number for made-to-order specifications

Specifications Table

| Tube Internal Diameter (mm) | 6 | 10 | 15 | 20 | 25 | 32 | 40 |

|---|---|---|---|---|---|---|---|

| Fluid | Air | ||||||

| Proof Pressure | 1.05 MPa | ||||||

| Maximum operating pressure | 0.7 MPa | ||||||

| Minimum operating pressure | 0.18 MPa | ||||||

| Ambient and fluid temperature | -10°C to +60°C (no freezing) | ||||||

| * Piston Speed | 50 to 400 mm/s | ||||||

| Cushioning | Rubber cushion / shock absorber | ||||||

| Lubrication | Not required | ||||||

| Stroke Length Tolerance (mm) | 0-250st: 0 to +1.0, 251 to 1,000st: 0 to +1.4, 1,001st to: 0~+1.8 | ||||||

| Magnetic retention force (N) | 19.6 | 53.9 | 137 | 231 | 363 | 588 | 922 |

- * When setting the auto switch to the intermediate position, the maximum piston speed that can be detected is restricted by the response time of the load (relay, sequence controller, etc.).

Standard Stroke Table

| Tube Internal Diameter (mm) | Standard Stroke (mm) | Manufacturable Maximum stroke (mm) |

|---|---|---|

| 6 | 50, 100, 150, 200 | 300 |

| 10 | 50, 100, 150, 200, 250, 300 | 500 |

| 15 | 50, 100, 150, 200, 250, 300, 350, 400, 450, 500 | 750 |

| 20 | 100, 150, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800 |

1,000 |

| 25 | 1,500 | |

| 32 | ||

| 40 | 100, 150, 200, 250, 300, 350, 400, 450, 500, 600, 700, 800, 900, 1,000 |

1,500 |

- * *1) The minimum manufacturable stroke is up to 15st without a switch or with 1 switch, and up to 25st with 2 switches.

- * *2) If there are multiple switches and the stroke is shorter than 25st (up to 15st), consider X431 (2 switch rail types).

Weight Table

(Unit: kg)

| Tube Internal Diameter (mm) | 6 | 10 | 15 | 20 | 25 | 32 | 40 | |

|---|---|---|---|---|---|---|---|---|

| CY1S□ | Basic weight | 0.231 | 0.428 | 0.743 | 1.317 | 1.641 | 2.870 | 4.508 |

| Additional weight per 50 strokes | 0.053 | 0.082 | 0.111 | 0.184 | 0.186 | 0.284 | 0.430 | |

| CY1SG□ | Basic weight | 0.236 | 0.435 | 0.743 | 1.331 | 1.662 | 2.903 | 4.534 |

| Additional weight per 50 strokes | 0.050 | 0.079 | 0.108 | 0.176 | 0.178 | 0.273 | 0.411 | |

Calculation method/example: CY1SG25-500

Basic weight (At 0 stroke): 1.662 kg / additional weight per 50 strokes: 0.178 kg

Cylinder Stroke: 500st

1.662 + 0.178×500 ÷ 50 = 3.442 kg

Shock Absorber Specifications

| Compatible cylinder | CY1S□6 | CY1S□10 | CY1S□15 | CY1S□20 | CY1S□25 | CY1S□32 | CY1S□40 |

|---|---|---|---|---|---|---|---|

| Shock absorber model | RJ0604 | RJ0806H | RJ0806L | RJ1007L | RJ1412L | RJ2015H | RJ2015L |

| Maximum energy absorption (J) | 0.5 | 1 | 3 | 10 | 30 | ||

| Stroke absorption (mm) | 4 | 6 | 7 | 12 | 15 | ||

| Collision speed (m/s) | 0.05 to 1 | 0.05 to 2 | 0.05 to 1 | 0.05 to 1 | 0.05 to 1 | 0.05 to 2 | 0.05 to 1 |

| Maximum frequency of use (cycle/min) | 80 | 80 | 70 | 45 | 25 | ||

| Max. allowable thrust (N) | 150 | 245 | 422 | 814 | 1961 | ||

| Ambient Temperature (°C) | -10°C to +60°C (no freezing) | ||||||

* *) The maximum absorbed energy and maximum frequency of use are the values at room temperature (approximately 20 to 25°C).

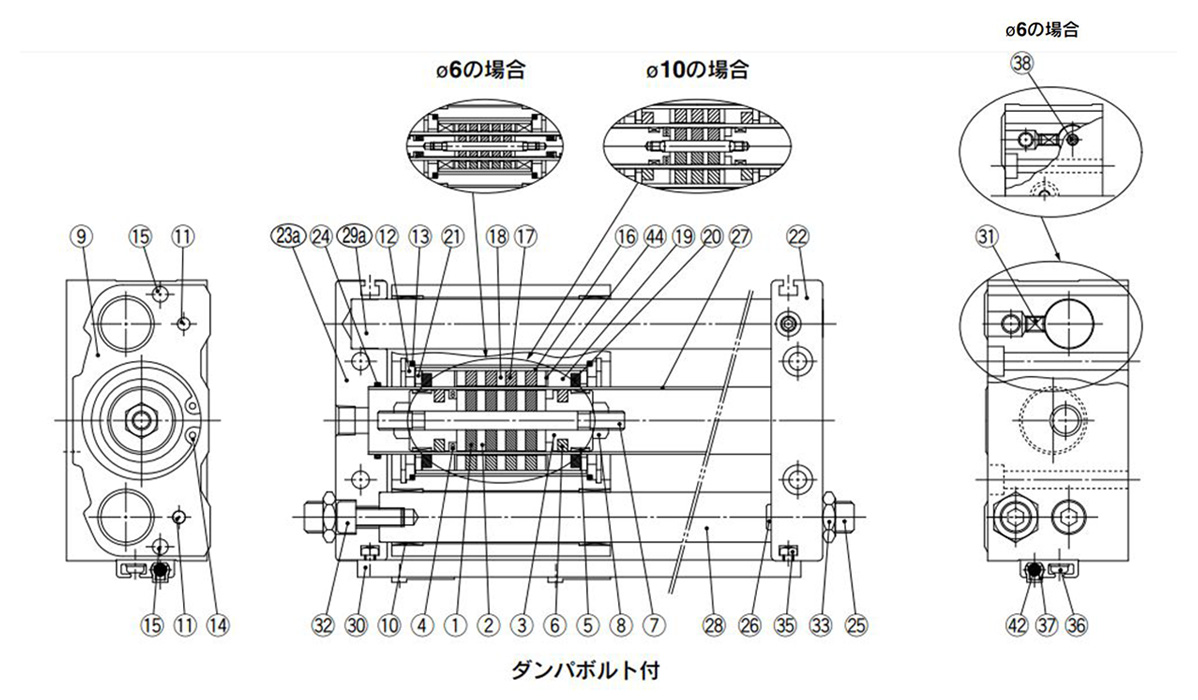

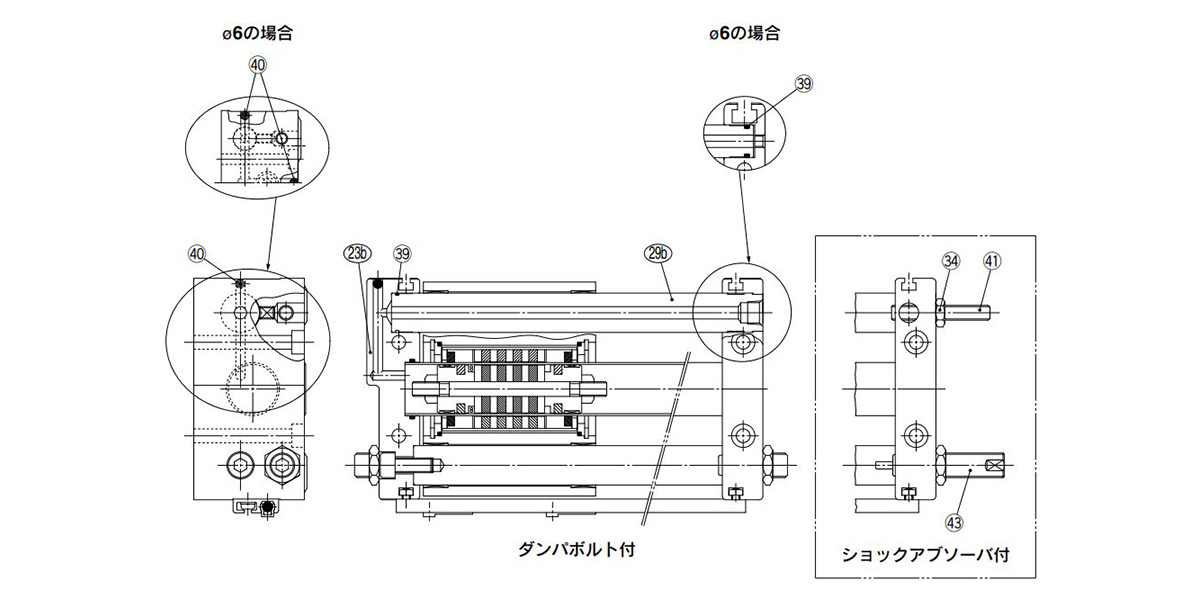

Diagram

CY1S / both sides piping type configuration diagram

Structural drawing of CY1SG / Centralized piping type

Components

| Number | Name | Material | Note |

|---|---|---|---|

| 1 | Magnet A | – | – |

| 2 | Piston-Side Yoke | Rolled steel | – |

| 3 | Piston | Aluminum alloy | – |

| *4 | Piston packing | NBR | – |

| *5 | Wear Ring A | Special resin | – |

| *6 | Lube-retainer A | Special resin | Excluding ø6 (diameter 6 mm) and ø10 (diameter: 10 mm) |

| 7 | Shaft | Stainless steel | – |

| 8 | Piston Nut | Carbon steel | Except ø6 (diameter: 6 mm) to ø15 (diameter: 15 mm) |

| 9 | Slide block | Aluminum alloy | – |

| 10 | Bushing | Resin/Copper alloy (Multiple layers) | – |

| 11 | Parallel pin | Carbon steel | – |

| 12 | Moving element spacer | Rolled steel | – |

| *13 | Mover gasket | NBR | – |

| 14 | Retaining Ring | Carbon tool steel | – |

| 15 | Magnet for switches | – | – |

| 16 | External Slider Tube | Aluminum alloy | – |

| 17 | Magnet B | – | – |

| 18 | External Slider Side Yoke | Rolled steel | – |

| *19 | Wear Ring B | Special resin | – |

| *20 | Lube-retainer B | Special resin | Except ø6 (diameter: 6 mm) |

| 21 | Spacer | Rolled steel | Except ø6 (diameter: 6 mm) |

| 22 | Plate A | Aluminum alloy | – |

| 23a | Plate C | Aluminum alloy | For piping on both sides |

| 23b | Plate B | Aluminum alloy | For centralized piping |

| *24 | Cylinder Tube Gasket | NBR | – |

| 25 | Bumper bolt | Chrome molybdenum steel | – |

| 26 | Damper | Urethane rubber | – |

| 27 | Cylinder Tube | Stainless steel | – |

| 28 | Guide shaft B | Carbon steel | Hard chrome plating |

| 29a | Guide shaft C | Carbon steel | Hard chrome plating |

| 29b | Guide shaft A | Carbon steel | Hard chrome plating |

| 30 | Switch rail | Aluminum alloy | – |

| 31 | Hex Socket Head Set Screw | Chrome molybdenum steel | – |

| 32 | Hex Socket Head Cap Screw | Chrome molybdenum steel | – |

| 33 | Hex Nut | Chrome molybdenum steel | – |

| 34 | Hex Nut | Chrome molybdenum steel | – |

| 35 | Square Nut | Chrome molybdenum steel | – |

| 36 | Cross-head machine screw with SW | Chrome molybdenum steel | – |

| 37 | Switch spacer | Special resin | – |

| 38 | Port plug | Chrome molybdenum steel | ø6 (diameter: 6 mm), piping on both sides only |

| *39 | Guide shaft gasket | NBR | For centralized piping |

| 40 | Steel ball | Bearing steel | For centralized piping |

| 41 | Adjusting bolt | Chrome molybdenum steel | – |

| 42 | Auto switch | – | – |

| 43 | Shock absorber | – | – |

| 44 | Liner | Aluminum alloy | – |

- * *1) The contents of the parts of the seal set are * -marked.

- * *2) Auto switch and switch spacer are shipped together.

Packing set

| Tube inner diameter (mm) |

Packing set | |

|---|---|---|

| Part No. | Details | |

| 6 | CY1S6-Z-PS | Above number 4, 5, 13, 19, 24, 39 |

| 10 | CY1S10-Z-PS | Above number 4, 13, 19, 20, 24, 39 |

| 15 | CY1S15-Z-PS | Above number 4, 5, 6, 13, 19, 20, 24, 39 |

| 20 | CY1S20-Z-PS | |

| 25 | CY1S25-Z-PS | |

| 32 | CY1S32-Z-PS | |

| 40 | CY1S40-Z-PS | |

- * *1) For the seal kit, the ø6 kit (inner diameter: 6 mm) includes 4, 5, 13, 19, 24, 39, and the ø10 kit (inner diameter: 10 mm) includes 4, 13, 19, 20, 24, 39, the kits for ø15 (inner diameter: 15 mm) to ø40 (inner diameter: 40 mm) include 4, 5, 6, 13, 19, 20, 24, 39 in 1 set, so please order using the order number for each tube inner diameter.

- * *2) A grease pack (10 g) is attached to the seal kit.

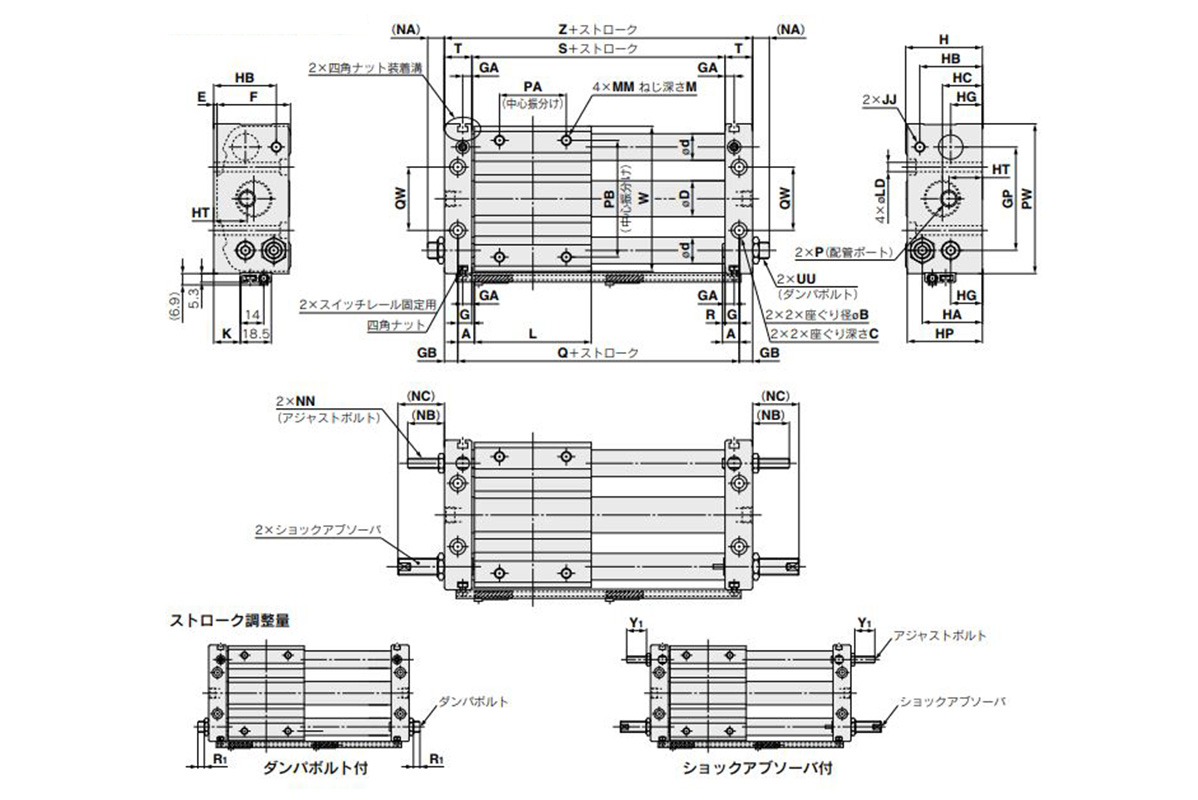

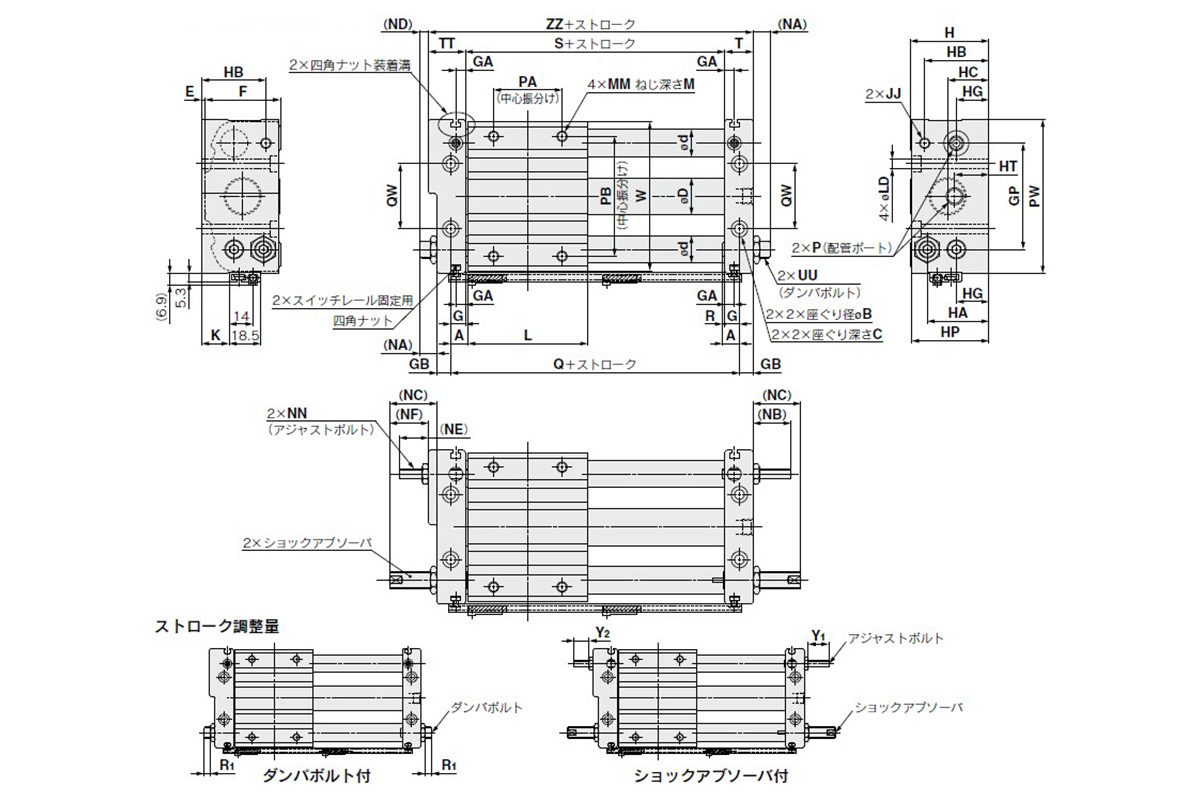

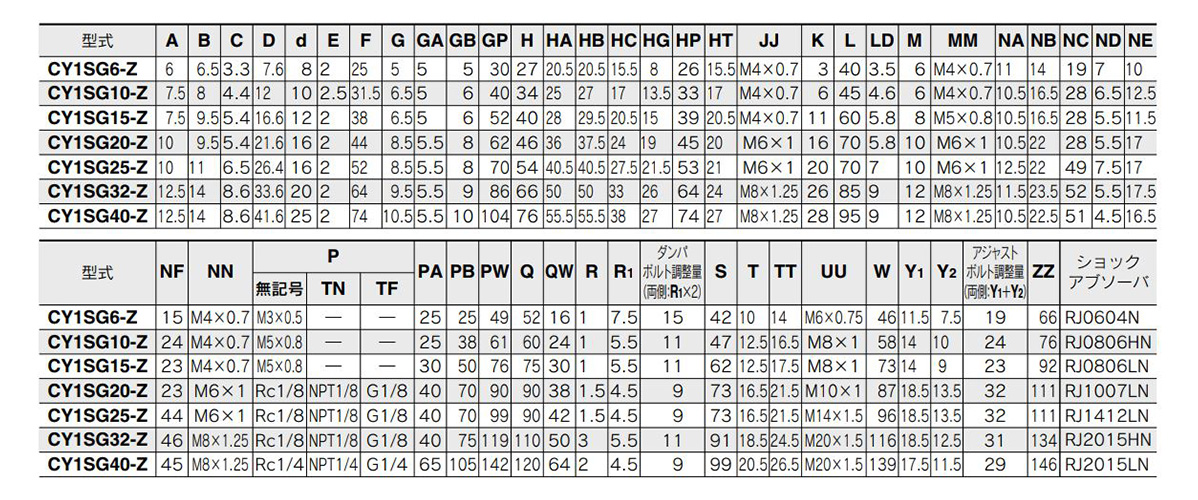

Dimensions of Magnet Type Rodless Cylinder, Slider Type / Slide Bearing CY1S Series

CY1S / both sides piping type

(Units: mm)

Dimensional drawing of CY1S / both sides piping type

(Units: mm)

Image of dimensions table for CY1S / both sides piping type

- * *) The above figure shows the case where the auto switch is installed. The auto switch and switch spacer are shipped together.

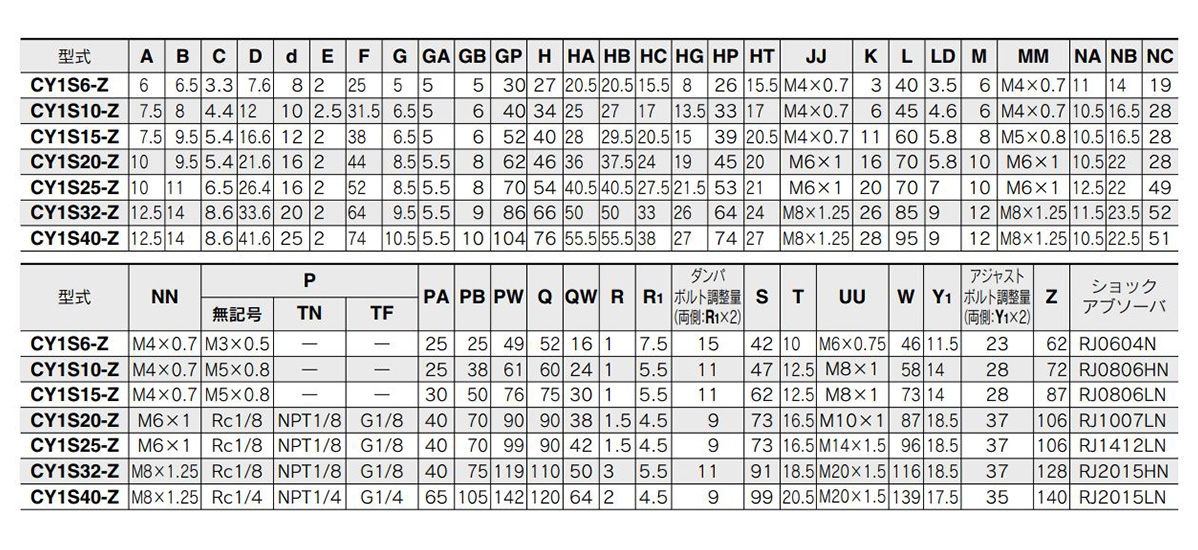

CY1SG / Centralized piping type

(Units: mm)

Dimensional drawing of CY1SG / Centralized piping type

(Units: mm)

Image of dimensions table for CY1SG / centralized piping type

- * *) The above figure shows the case where the auto switch is installed. The auto switch and switch spacer are shipped together.

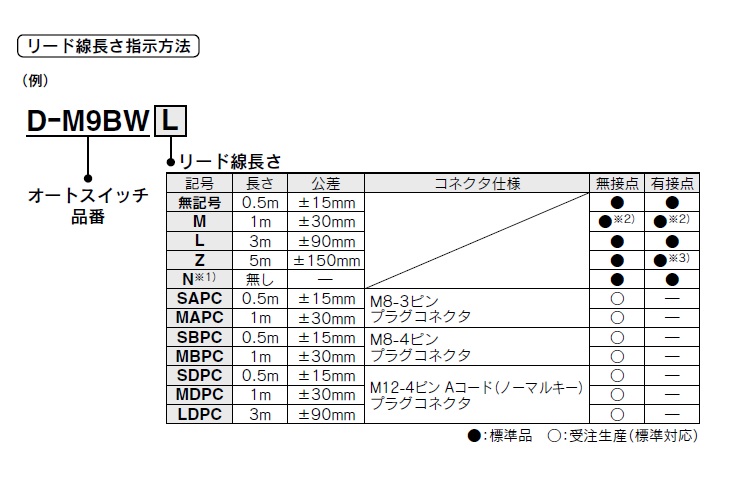

Please refer to the table below for details about lead wire / connector specifications.

Basic Information

| Type | Rodless Cylinder | Table Material | Aluminum Alloy | Rodless Cylinder Joint Type | Magnetic |

|---|---|---|---|---|---|

| Environment | General Purpose | Table Surface Treatment | No | Guide Type | Guide Type of Slide Bearing |

| Switch Rail | Yes | Specifications | Magnet built-in | Custom-made Specifications | 0.18 to 0.7 |

CY1S6-15Z

CY1S6-20Z

CY1S6-30Z

CY1S6-30Z-M9BW

CY1S6-50BSZ

CY1S6-50BSZ-A93L

CY1S6-50BSZ-A93V

CY1S6-50BZ-A93

CY1S6-50BZ-M9B

CY1S6-50BZ-M9BL

CY1S6-50BZ-M9BW

CY1S6-50BZ-M9NWL

CY1S6-50BZ-M9NWV

CY1S6-50BZ-M9PVL

CY1S6-50Z

CY1S6-50Z-A93

CY1S6-50Z-M9BAL

CY1S6-50Z-M9BL

CY1S6-50Z-M9BS

CY1S6-50Z-M9BW

CY1S6-50Z-M9BWL

CY1S6-50Z-M9N

CY1S6-50Z-M9NV

CY1S6-60BZ

CY1S6-60BZ-M9BW

CY1S6-60Z

CY1S6-60Z-M9BW

CY1S6-62Z-M9BW

CY1S6-63Z

CY1S6-65BSZ-M9B

CY1S6-65BZ

CY1S6-65BZ-M9BL

CY1S6-65Z

CY1S6-65Z-M9B

CY1S6-65Z-M9NV

CY1S6-65Z-X2423

CY1S6-70BSZ-M9BS

CY1S6-70Z

CY1S6-70Z-M9BS

CY1S6-75BZ

CY1S6-75BZ-M9NW

CY1S6-75Z-A93

CY1S6-80Z-A93L

CY1S6-100BSZ

CY1S6-100BSZ-M9BW

CY1S6-100BZ-A93

CY1S6-100BZ-A93L

CY1S6-100BZ-A96V

CY1S6-100BZ-M9BAL

CY1S6-100BZ-M9BL

CY1S6-100BZ-M9BM

CY1S6-100BZ-M9BVL

CY1S6-100BZ-M9BW

CY1S6-100BZ-M9NWV

CY1S6-100Z-A93

CY1S6-100Z-A93L

CY1S6-100Z-M9BA

CY1S6-200BZ-M9BW

CY1S6-200BZ-M9BWL

CY1S6-200BZ-M9NV

CY1S6-200BZ-M9NWL

CY1S6-200Z

CY1S6-200Z-A93

CY1S6-200Z-A93V

CY1S6-200Z-M9B

CY1S6-200Z-M9BL

CY1S6-200Z-M9BW

CY1S6-200Z-M9BWMS

CY1S6-200Z-M9N

CY1S6-200Z-M9NL

CY1S6-200Z-M9NV

CY1S6-200Z-M9NWM

CY1S6-200Z-X2423

CY1S6-210BSZ

CY1S6-210BZ

CY1S6-210Z

CY1S6-225BSZ

CY1S6-225Z

CY1S6-240BZ

CY1S6-240Z

CY1S6-250BZ

CY1S6-250BZ-A93

CY1S6-250Z

CY1S6-250Z-A93

CY1S6-250Z-M9N

CY1S6-250Z-M9N-X242

CY1S6-250Z-XB9

CY1S6-260Z

CY1S6-270BZ-M9BWL

CY1S6-270Z

CY1S6-290Z-M9N

CY1S6-290Z-M9N-X2423

CY1S6-290Z-M9N-XB13

CY1S6-300BSZ

CY1S6-300BSZ-A93

CY1S6-300BZ

CY1S6-300BZ-A93

CY1S6-300BZ-M9B

CY1S6-300BZ-M9BW

CY1S6-300BZ-M9NWM

CY1S6-300Z

CY1S6-300Z-A93

CY1S10-30Z

CY1S10-35BSZ-M9B

CY1S10-35Z

CY1S10-40BZ

CY1S10-40Z

CY1S10-40Z-M9BL

CY1S10-40Z-M9BW-XB9

CY1S10-50BSZ

CY1S10-50BSZ-A93

CY1S10-50BSZ-M9BL

CY1S10-50BZ

CY1S10-50BZ-A93L

Giới thiệu SMC Việt Nam

SMC là thương hiệu hàng đầu thế giới trong lĩnh vực công nghệ khí nén, cung cấp các giải pháp tiên tiến nhằm hỗ trợ tự động hóa và tối ưu hóa quy trình sản xuất.

Với nền tảng vững chắc trong ngành, SMC Việt Nam luôn đi đầu trong việc nghiên cứu, đổi mới và phát triển sản phẩm, góp phần nâng cao năng suất và tiết kiệm lao động cho các doanh nghiệp công nghiệp.

Với phương châm “đóng góp vào tự động hóa và tiết kiệm lao động trong ngành công nghiệp”, SMC Việt Nam không ngừng cải tiến và mang đến những sản phẩm công nghệ tiên tiến nhất.

SMC Việt Nam cam kết cung cấp những giải pháp hiện đại, giúp khách hàng duy trì lợi thế cạnh tranh trên thị trường.

Medin Company cung cấp các sản phẩm SMC tại Việt Nam.

Đa dạng các sản phẩm và giải pháp khí nén phục vụ cho nhiều ngành công nghiệp khác nhau, bao gồm:

- Xy lanh khí nén – Giúp kiểm soát chuyển động chính xác và hiệu quả.

- Van điện từ – Ứng dụng rộng rãi trong điều khiển luồng khí nén.

- Bộ lọc khí nén – Đảm bảo chất lượng khí nén tối ưu.

- Cảm biến và bộ điều khiển – Tăng cường tự động hóa trong quy trình sản xuất.

———————-

👉 Xem thêm sản phẩm của SMC

Liên Hệ Medin Co., Ltd

- Công ty TNHH Mễ Đình được thành lập từ năm 2006.

- Từ đó đến nay Medin luôn là Công ty dẫn đầu về lĩnh vực Tự Động Hoá ở thị trường trong và ngoài nước với hơn 1,000 khách hàng, cùng với rất nhiều dự án lớn nhỏ cho các nhà máy sản xuất.

- Chúng tôi cung cấp cho khách hàng những giải phát tuyệt vời nhất trong việc ứng dụng Tự Động Hoá vào sản xuất

- Phương châm: “Giải pháp của chúng tôi, lợi ích của khách hàng”

- Giá trị cốt lõi: “Uy tín là sự tồn tại của chúng tôi”

- Hơn 20 năm kinh nghiệm, chúng tôi có đội ngũ kỹ sư nhiều kinh nghiệm, có khả năng tư vấn, đưa ra giải pháp có lợi nhất cho khách hàng.

- Sự tin tưởng và đồng hành của khách hàng là động lực để Medin phát triển cao hơn và xa hơn.