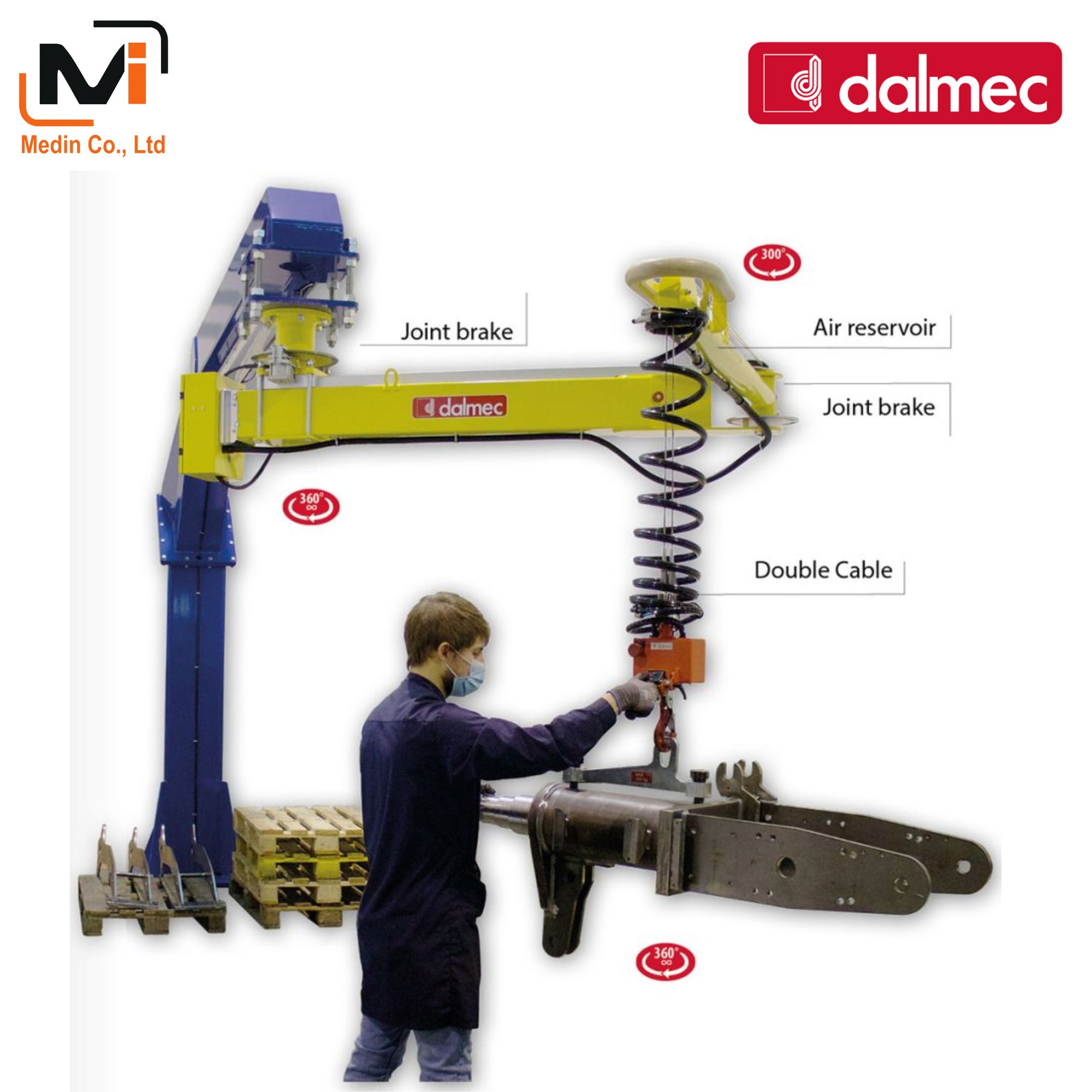

PNEUMATIC MANIPULATOR POSIPLUS PP WITH DOUBLE CABLE

POSIPLUS PP is a double cable manipulator with high load capacities, capable of handling loads up to 200 kg and reaching working radii up to 4500 mm. The gripping tooling is connected to the balancing group through two independent steel cables to ensure maximum safety. The particular double-arm structure with intermediate joint makes it easy to operate within the entire working area. Specific brakes mounted on the main joints guarantee control of drift movements.

OPERATION

A pneumatic cylinder fed with compressed-air, combined with a transmission cables system provides balance to the load weight applied.

The cylinder force is controlled through two pneumatic circuits purposely arranged: the first one always keeps the weight system balanced; the second one provides to always keep the weight load balanced.

The operator can change the load level applying a minimum force on the gripping tool or directly on the load.