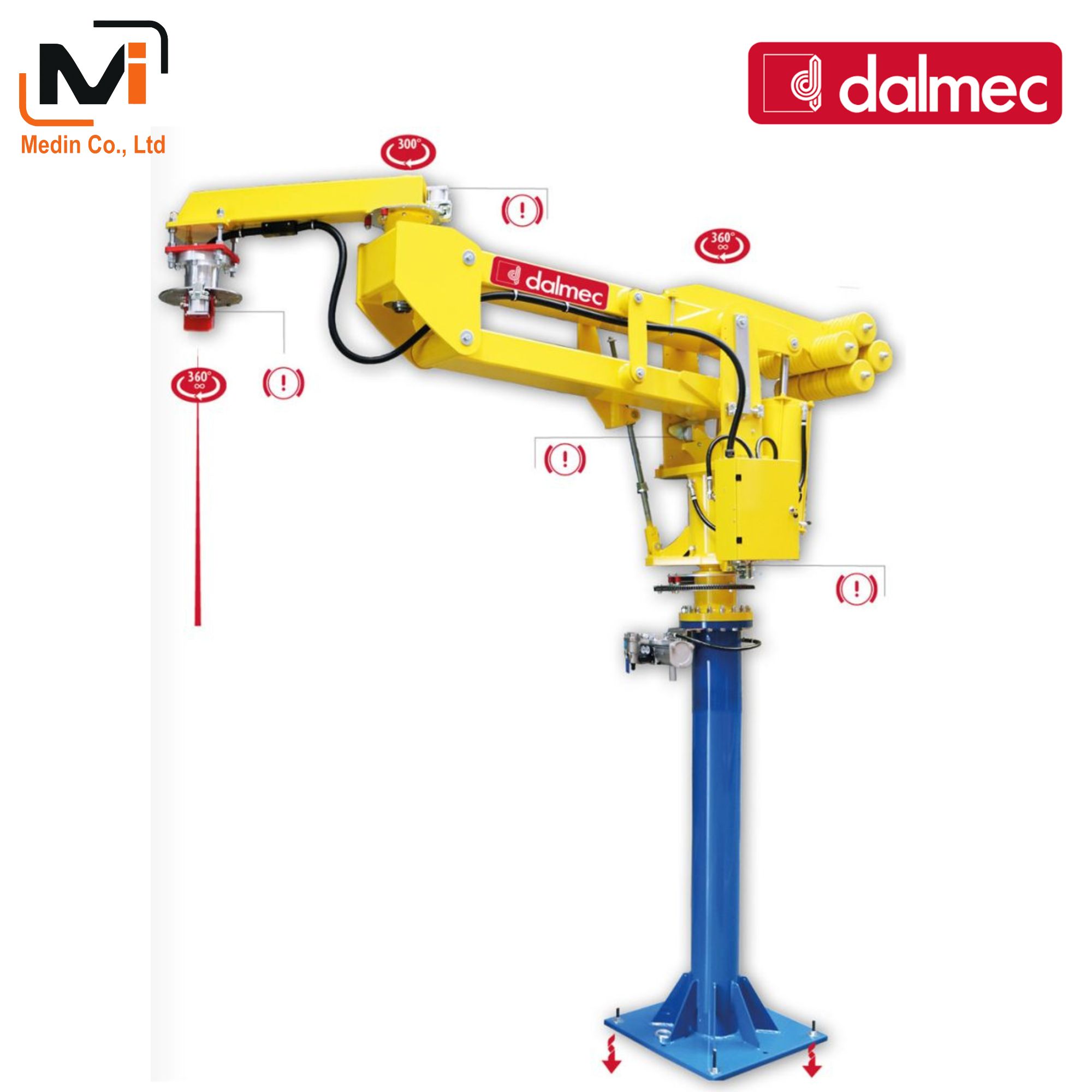

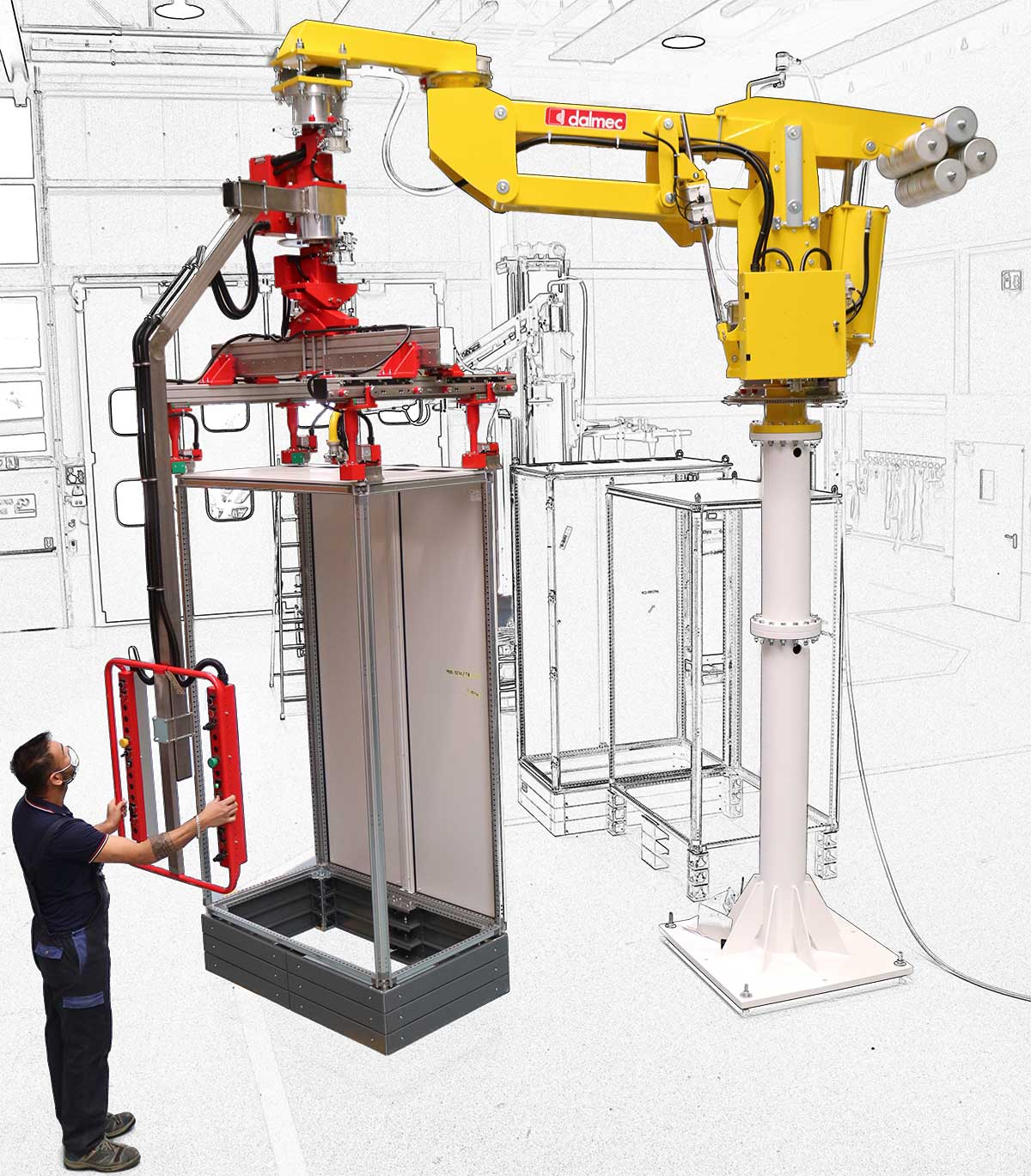

MANIPULATOR WITH ARTICULATED ARMS MEGAPARTNER MG

Pneumatic Manipulator MEGAPARTNER MG with articulated arms, equipped with special gripping tools, is suitable to handle heavy (max 1500 kg) and also off-set loads, in any direction, allowing the operator to work with the minimum effort in good ergonomic and safety conditions.